Automobile part carrying protective shell with shock absorption function

A technology for auto parts and protective cases, which is applied in the field of protective cases for carrying auto parts, which can solve problems such as damage to auto parts, poor shock-absorbing function, and the lack of shock-absorbing function of the protective case, so as to reduce the probability of damage, facilitate use, and Avoid the effect of excessive shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

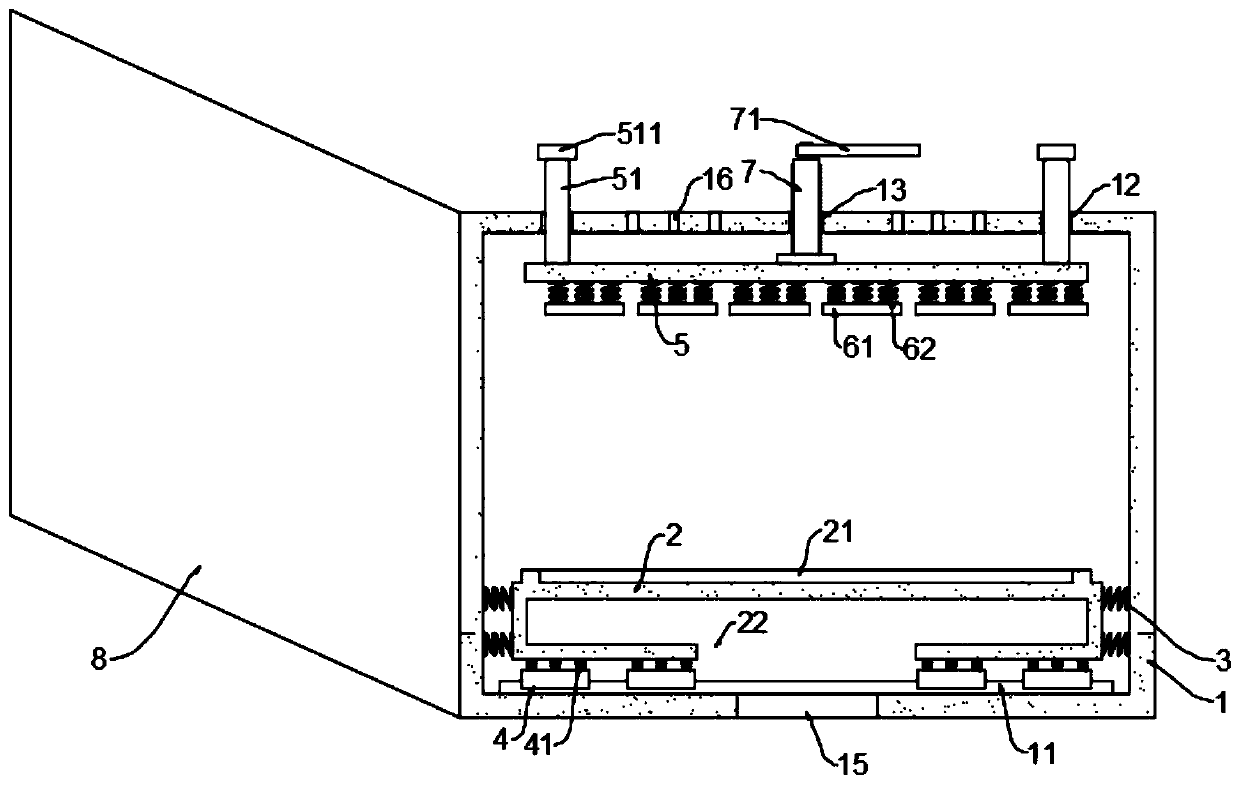

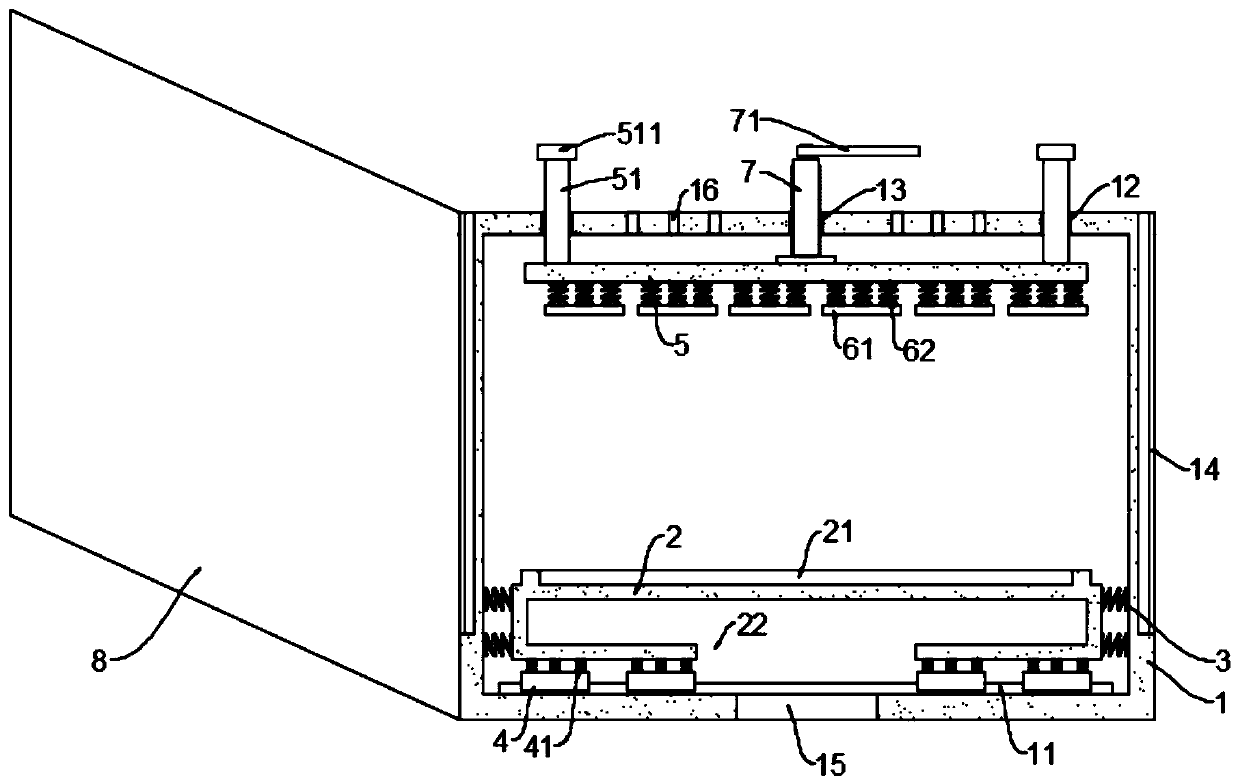

[0024] see figure 1 , in an embodiment of the present invention, a protective case for carrying automobile parts with a cushioning function, comprising a box body 1 and a box door 8 arranged at the front opening of the box body 1; a bearing seat 2 is arranged inside the box body 1 , the side of the bearing seat 2 is connected with the inner wall of the box body 1 through the first shock absorbing spring 3 , the support seat 4 is arranged under the bearing seat 2 , and the top of the supporting seat 4 is connected with the inner wall of the bearing seat 2 through the second shock absorbing spring 41 . Bottom connection, the bottom of the support seat 4 is slidingly connected to the bottom of the inner cavity of the box body 1. When in use, the auto parts are placed on the support seat 4. During the transportation process, the first damping spring 3 performs horizontal shock absorption. The vertical shock absorption is performed by the second shock absorbing spring 4, so as to r...

Embodiment 2

[0035] see Figure 2~4 , the embodiment of the present invention expands the function on the basis of embodiment 1, specifically:

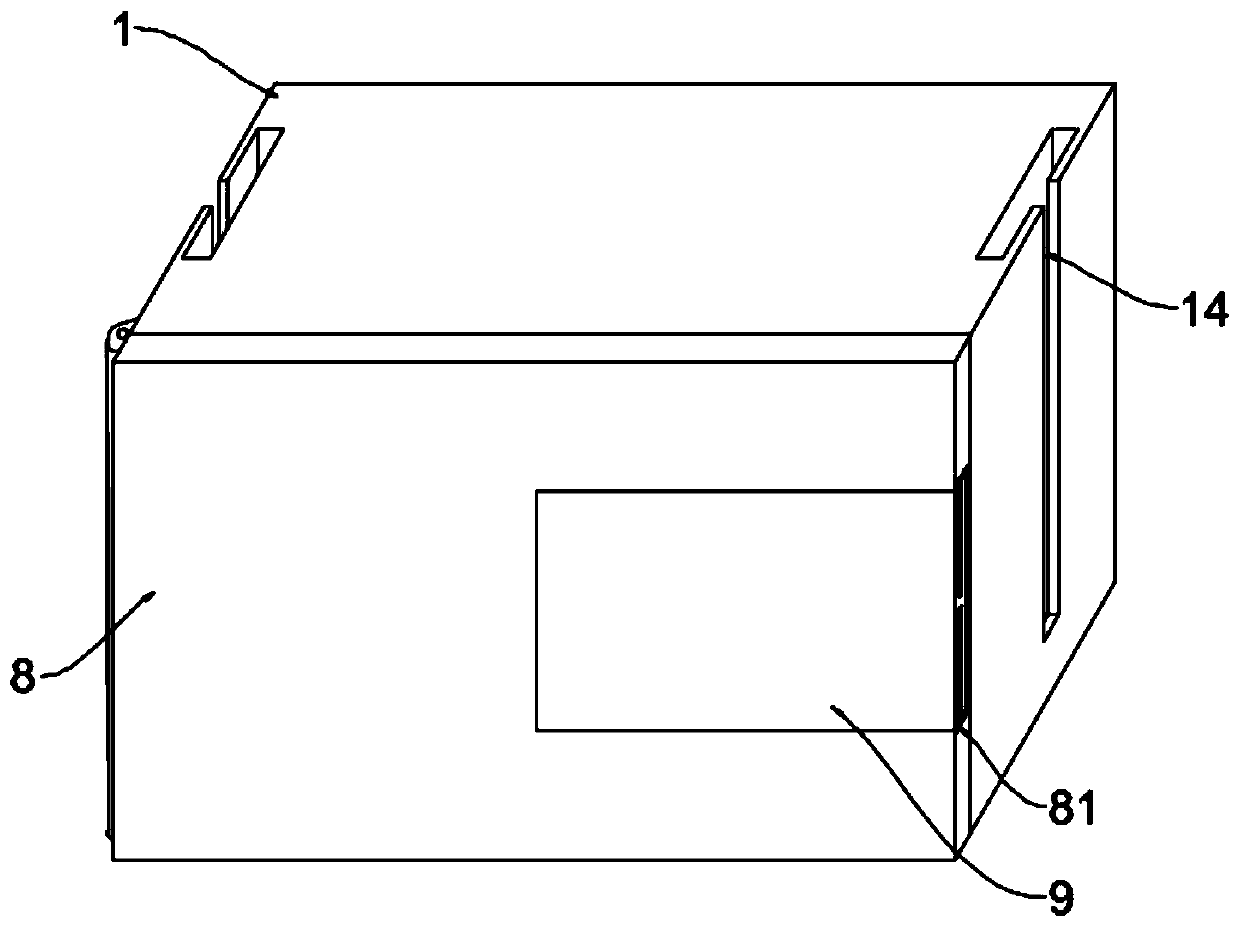

[0036] The side outer wall of the box body 1 is provided with a card slot 14, the cross section of the card slot 14 is "T" shaped, the box door 8 is provided with a slot 81, and the slot 81 is provided with a connecting block 9. The cross-section of the connecting block 9 presents a shape formed by splicing the cross-sections of two slots 14, so that when in use, the connecting block 9 can be inserted into the slots 14 of two adjacent boxes 1, thereby completing two The combination of the boxes 1 is convenient for overall transportation.

[0037] To sum up, in this embodiment, by setting the card slot 114 and the connecting block 9, the combined connection between two adjacent boxes 1 can be carried out, which is convenient for transportation, so that the connecting block 9 is embedded in the box door 8 , can avoid the loss of the connection blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com