Double-sided multi-linkage hot rolling spring forming mechanism

A spring forming, bilateral technology, used in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, large quality, large floor space, etc., to achieve high production efficiency, improve production efficiency, avoid The effect of manual positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

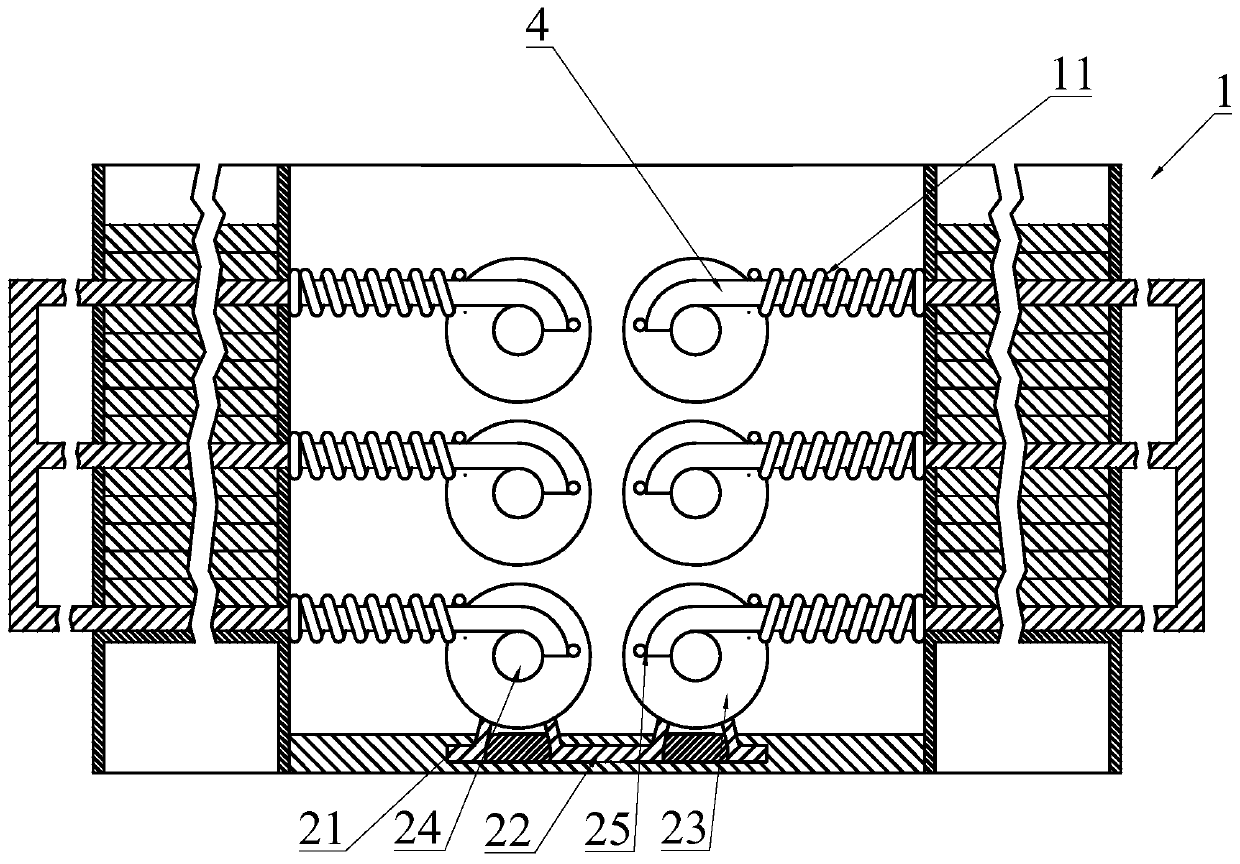

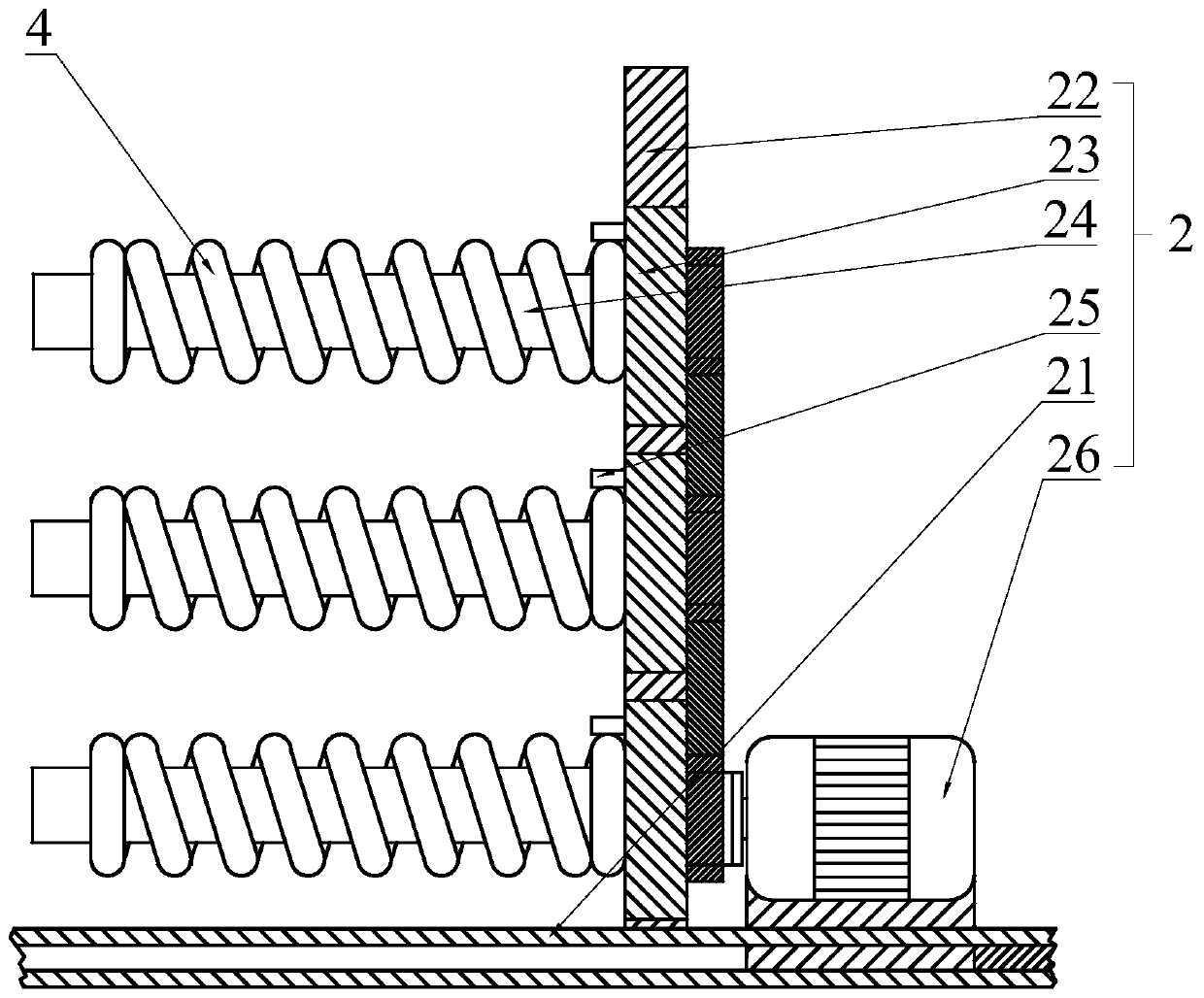

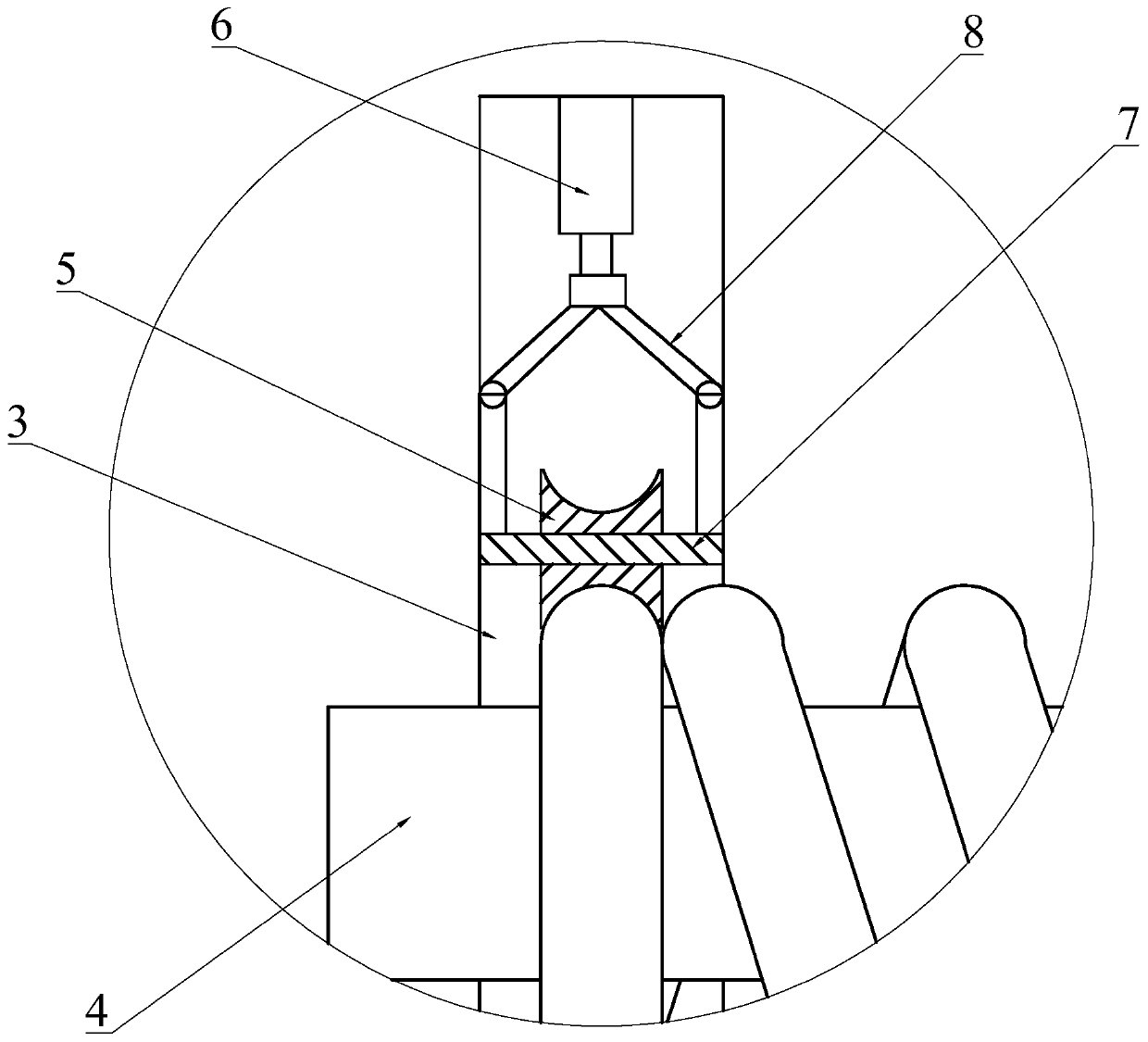

[0014] see figure 1 , figure 2 and image 3 As shown, the double-sided multi-linkage hot-rolled spring forming mechanism of the present invention includes a heating assembly 1 and a torsion assembly 2, and is characterized in that the torsion assembly 2 includes two parallel rails 21 and a turntable 23 arranged on the rails 21 Frame 22, described turntable 23 frame 22 is vertically provided with at least two turntables 23, and described rail 21 is also provided with the motor 26 that is relatively fixed with turntable 23 frame 22, and described turntable 23 is connected with motor 26 is a drive plate connected by transmission. The rotating disc 23 is provided with a main shaft 24 and a positioning pin 25. The heating assembly 1 is divided into two groups and arranged symmetrically on both sides of the twisting assembly 2. The heating assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com