Double-edge hot-rolling spring forming mechanism

A spring forming, bilateral technology, used in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of high quality and low production efficiency, and achieve high production efficiency, improve production efficiency, and reduce operational risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

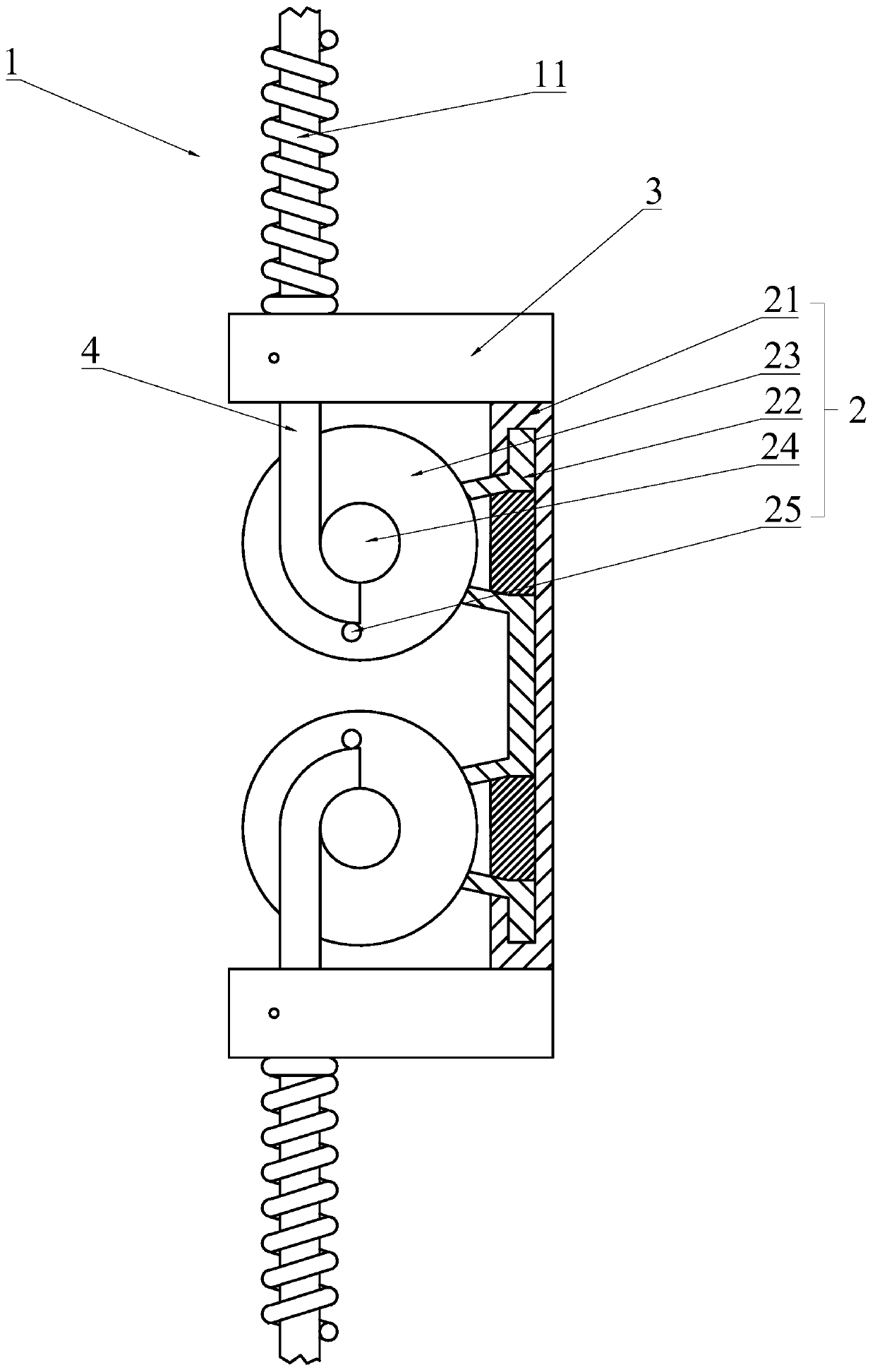

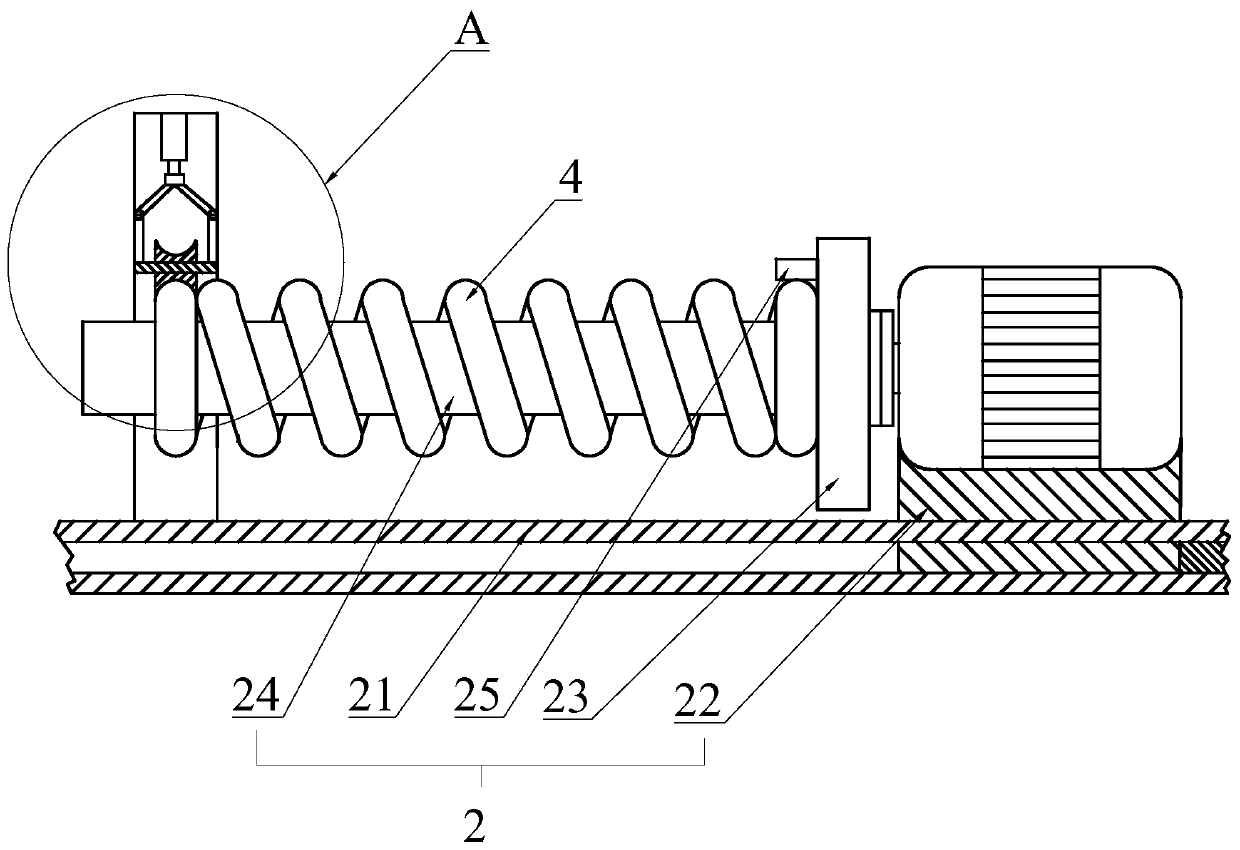

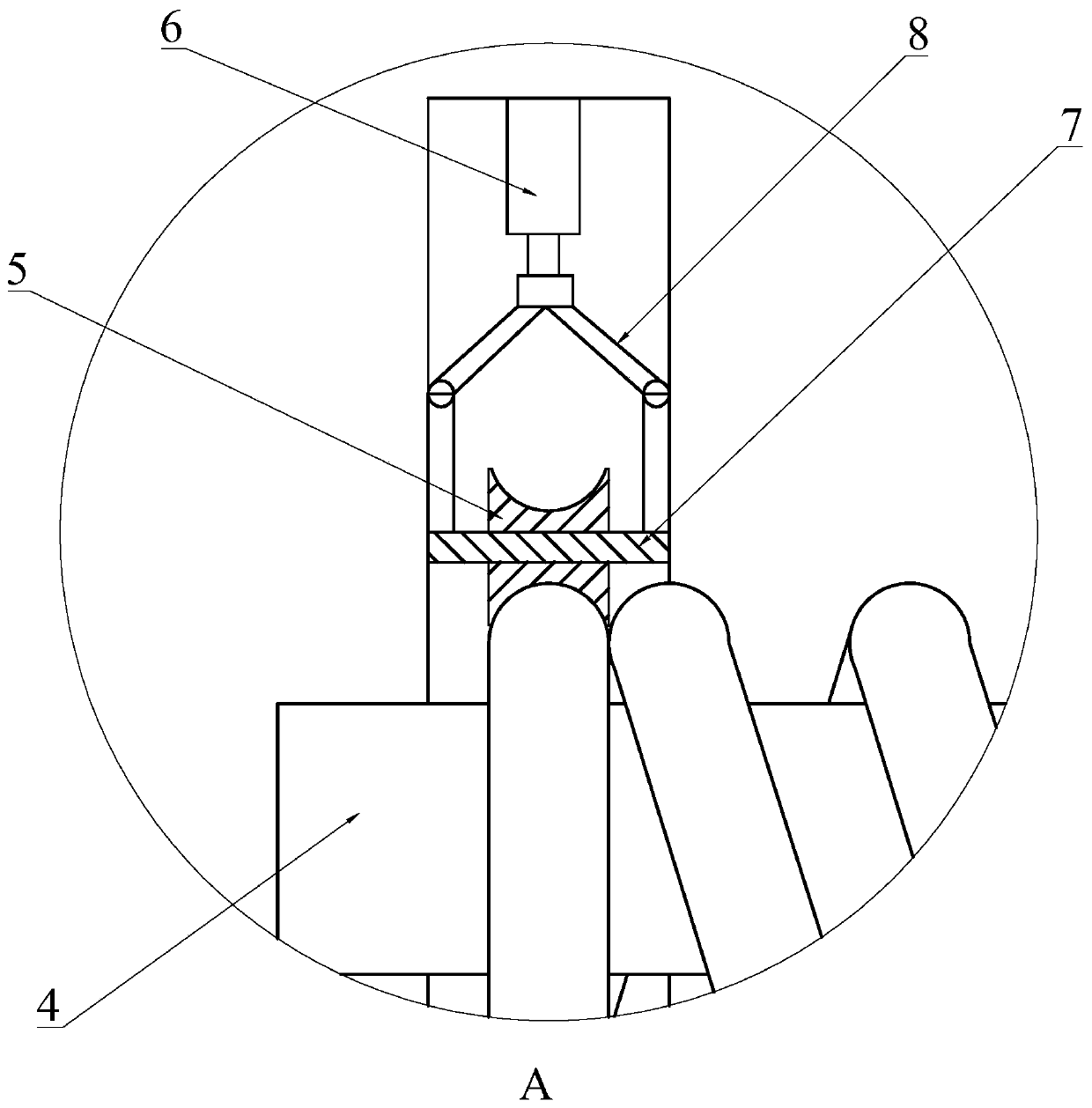

[0015] see figure 1 , figure 2 and image 3 As shown, a double-sided hot-rolled spring forming mechanism of the present invention includes a heating assembly 1 and a torsion assembly 2. The torsion assembly 2 includes two parallel rails 21 and a sliding bracket 22 arranged on the rails 21. The sliding bracket 22 is provided with a turntable 23, the turntable 23 is provided with a main shaft 24 and a positioning pin 25, and the turntable 23 is respectively driven by two motors or driven by a motor drive, and also includes a heating assembly 1 and a The positioning assembly between the torsion assemblies 2, by setting two parallel rails 21 and the sliding bracket 22 arranged on the rails 21, there can be two simultaneously rotating turntables 23 at the same time, that is, two sets of correspondingly arranged heating assemblies 1, which can Tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com