A plate and wire welding fixture

A welding fixture and wire technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as wire fixing, achieve long service life, good quality of solder joints, and solve the effect of low welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

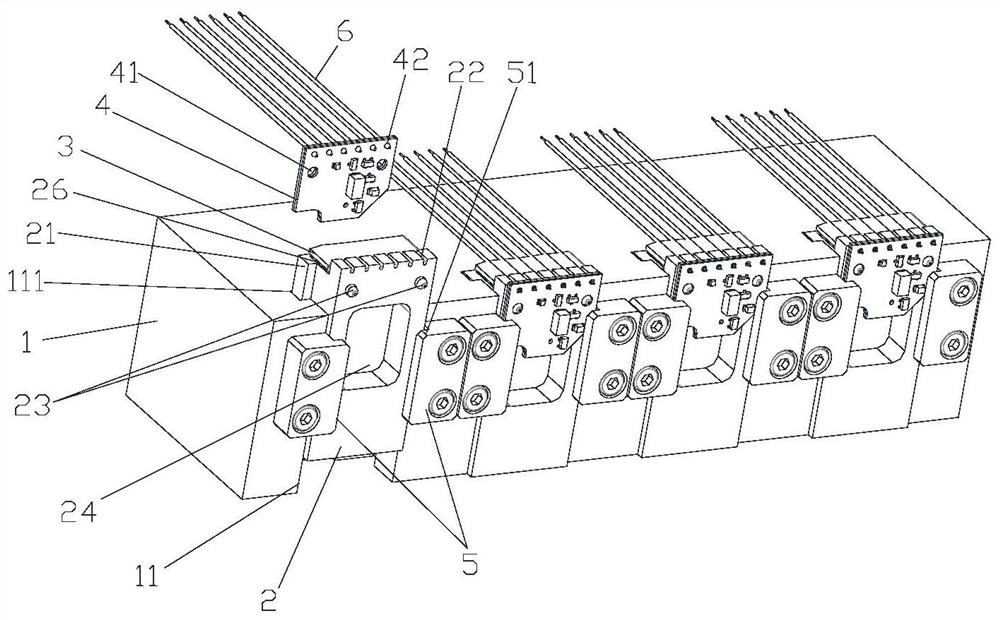

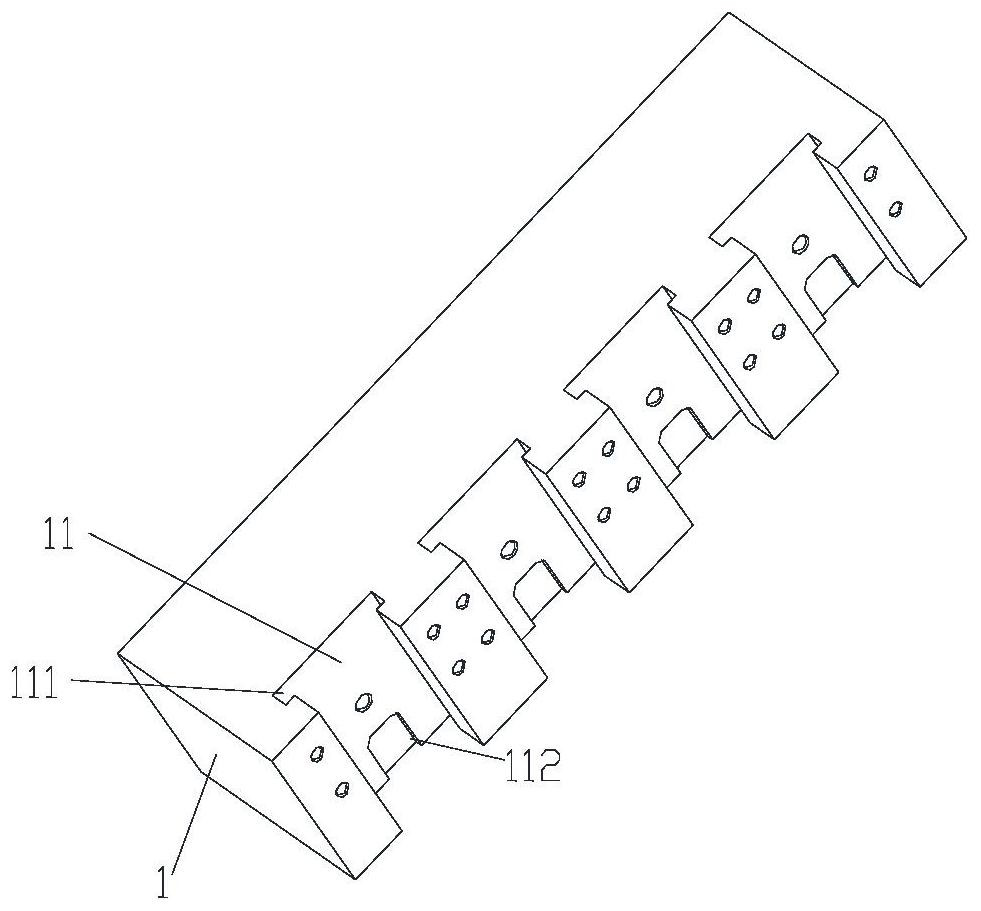

[0040] Such as Figure 1 ~ Figure 4 As shown, a plate and wire welding fixture of the present invention includes:

[0041] Base 1, the base 1 is provided with a slider engagement chute 11, the slider engagement chute 11 is a T-shaped structure, and the bottom of the slider engagement chute 11 has an inner groove structure 111;

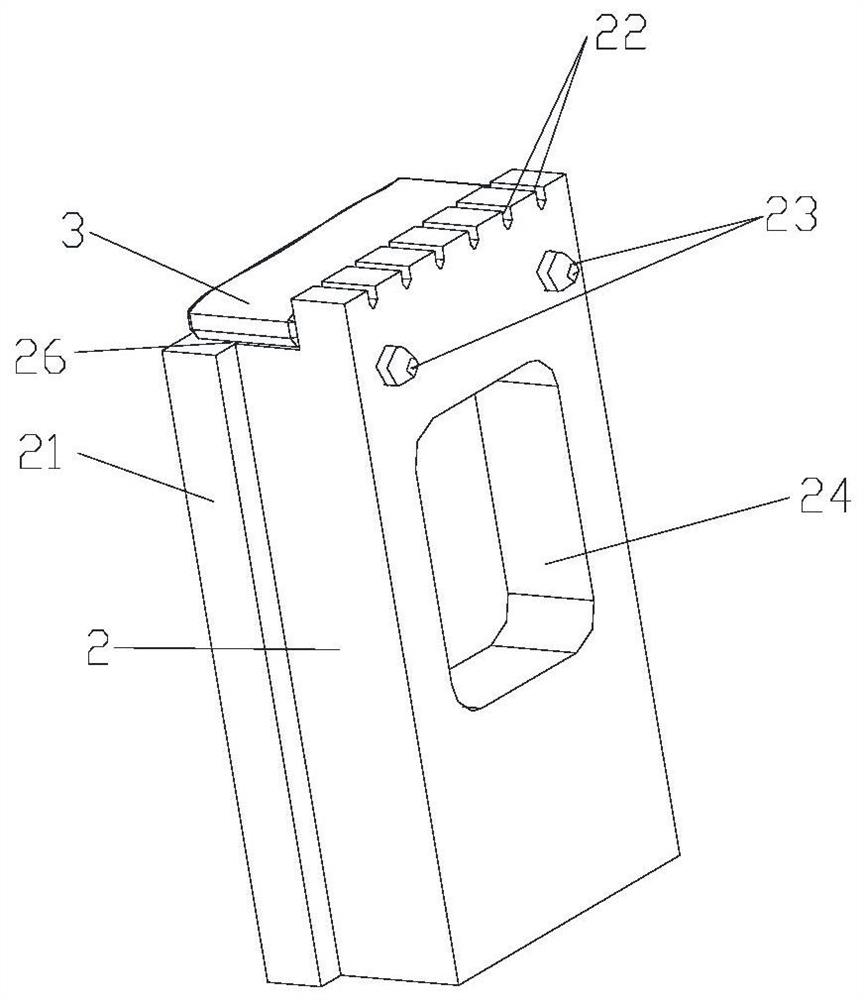

[0042] A plurality of sliders 2, the bottom end of the slider 2 is provided with a protruding structure 21, and the protruding structure 21 and the inner groove structure 111 are slidably connected to each other, so as to realize the sliding connection between the slider 2 and the base 1; The side of the slider 2 connected to the PCB board 4 to be welded is provided with a positioning pin 23, and the positioning pin 23 is used for positioning and fixing the PCB board 4 to be welded by cooperating with the positioning hole 41 on the PCB board 4 to be welded; One end of the slider 2 is provided with a slider table 26 and some arc grooves 22. When the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com