A high-performance fastener spring, its manufacturing method and application

A high-performance, elastic bar technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problem of low fatigue life of elastic bars, achieve the effect of increased raw material costs, good promotion and application prospects, high strength, toughness, and high cycle fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

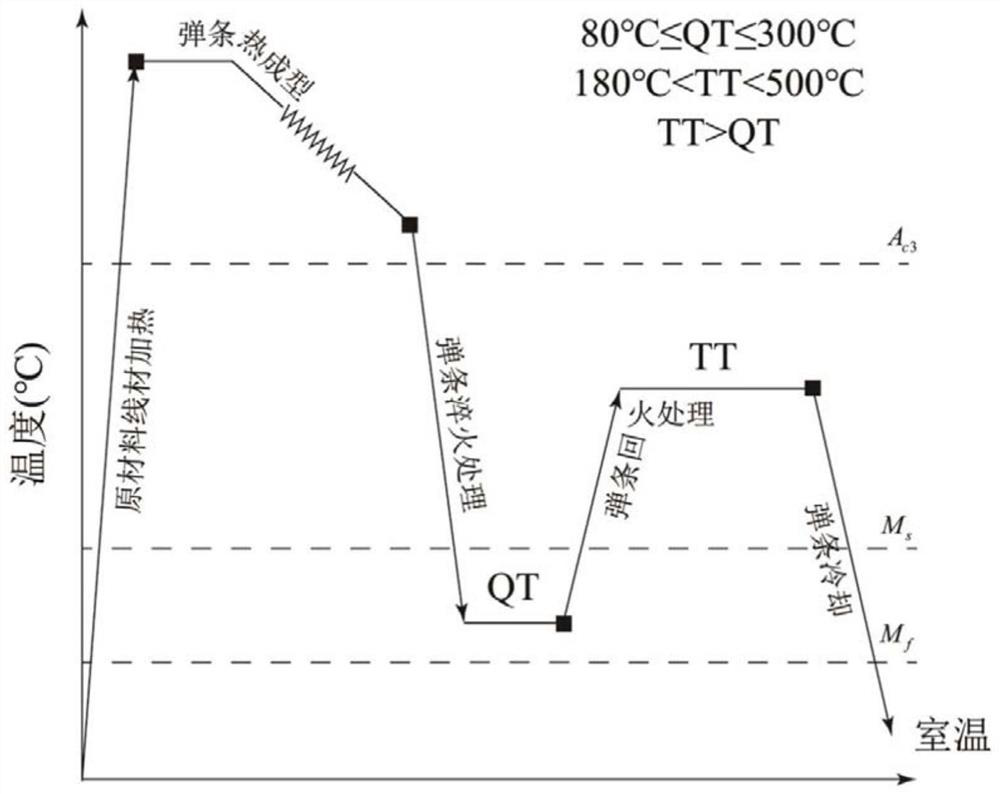

[0077] A raw material wire for fastener clips, the mass percent of its chemical composition is: C=0.58%, Si=1.73%, Mn=0.88%, Cr=0.27%, Pfigure 1 As shown, the preparation method of the high-performance fastener elastic strip comprises the steps:

[0078] 1) Thermoforming of spring raw material wire:

[0079] The raw material wire (diameter 20mm) with the above chemical composition was heated to 1050°C, kept for 0.3h, and then the soaked wire was bent and formed into an "e-shaped" spring bar, and the forming temperature was 850°C.

[0080] 2) Quenching and tempering treatment of spring bars:

[0081] Quench and cool the hot-formed elastic bars at a cooling rate of about 80°C / s to the quenching temperature (QT) of 140°C, the temperature before quenching is 850°C, and the quenching and holding time is 2 minutes; then, temper the quenched elastic bars For treatment, heat the quenched elastic strip at a heating rate of about 35°C / s to the tempering temperature (TT) of 410°C, and h...

Embodiment 2

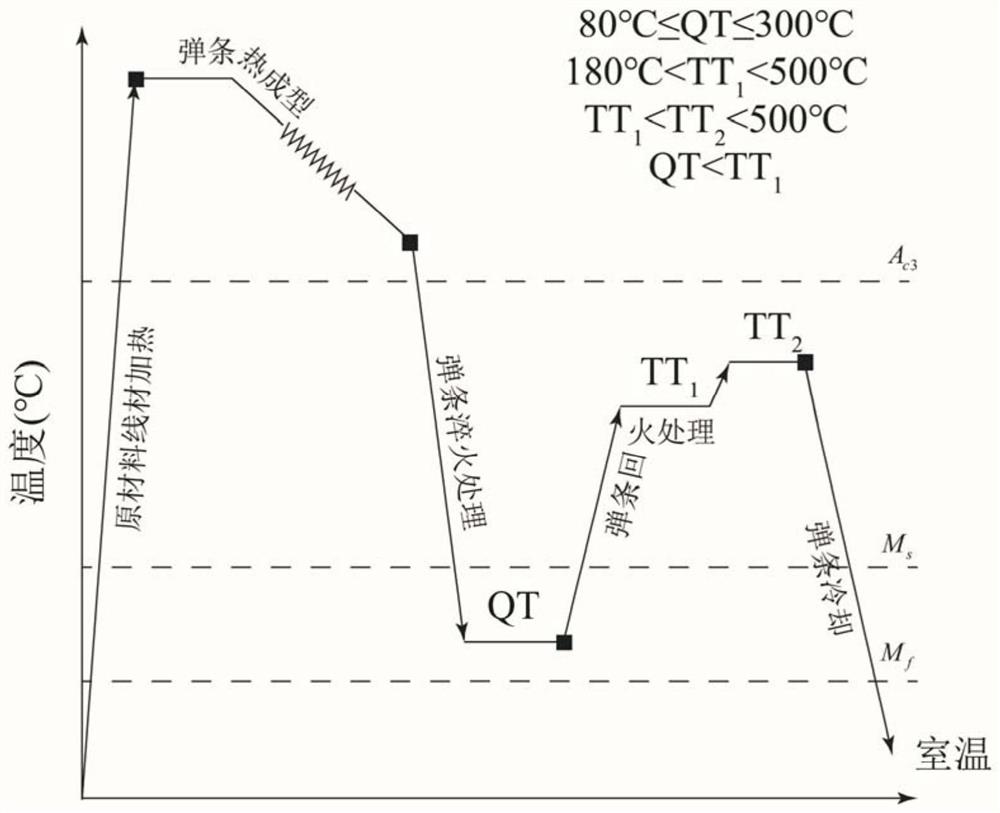

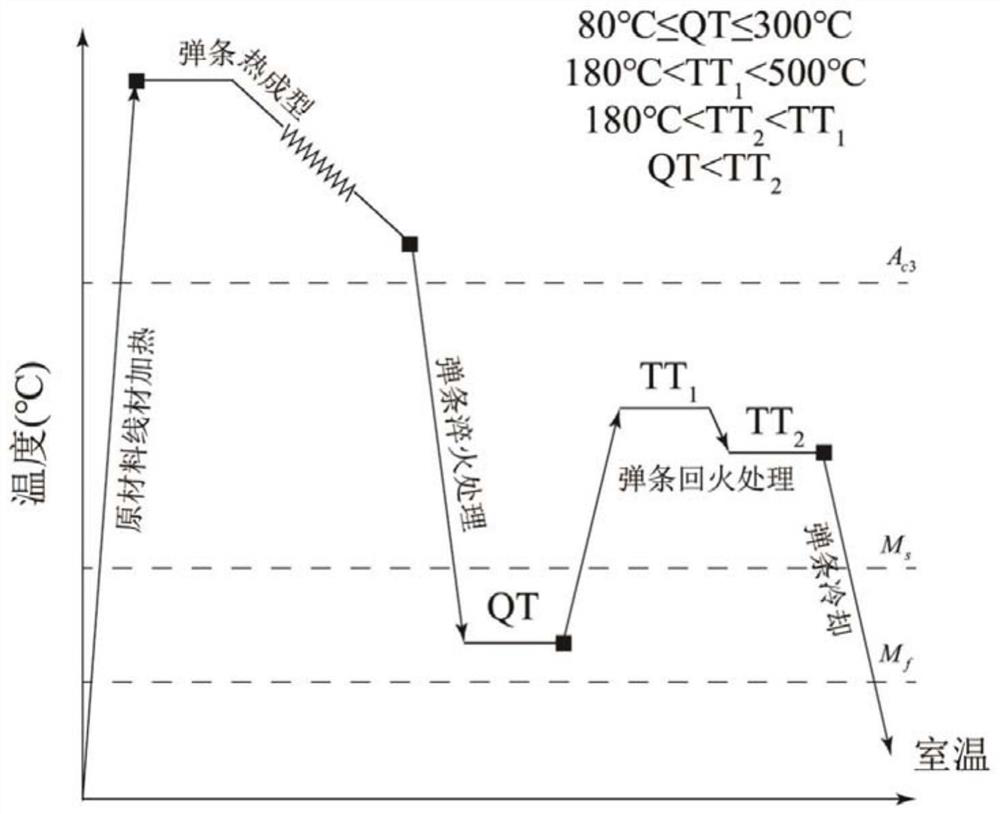

[0089] A raw material wire for fastener clips, the mass percent of its chemical composition is: C=0.48%, Si=1.2%, Mn=1.5%, Nb=0.2%, P figure 2 As shown, the preparation method of the high-performance fastener elastic strip comprises the steps:

[0090] 1) Thermoforming of spring raw material wire:

[0091] The raw material wire (diameter 20mm) with the above chemical composition was heated to 1050°C, kept for 0.3h, and then the soaked wire was bent and formed into an "e-shaped" spring bar, and the forming temperature was 850°C.

[0092] 2) Quenching and tempering treatment of spring bars:

[0093] Quench and cool the hot-formed elastic bars at a cooling rate of about 80°C / s to the quenching temperature (QT) of 100°C, the temperature before quenching is 850°C, and the quenching and holding time is 2 minutes; then, implement two-stage cooling on the quenched elastic bars For tempering treatment, first heat the quenched elastic strip at a heating rate of about 35°C / s to the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com