Supporting device and supporting method for solid rocket engine end face combustion grain

A solid rocket, end face combustion technology, applied in rocket engine devices, machines/engines, jet propulsion devices, etc., can solve the problems of grain sloshing, unsafe, uneven stress on grain surface ventilation, etc., to avoid cracking, improve Stress condition, unique high temperature resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

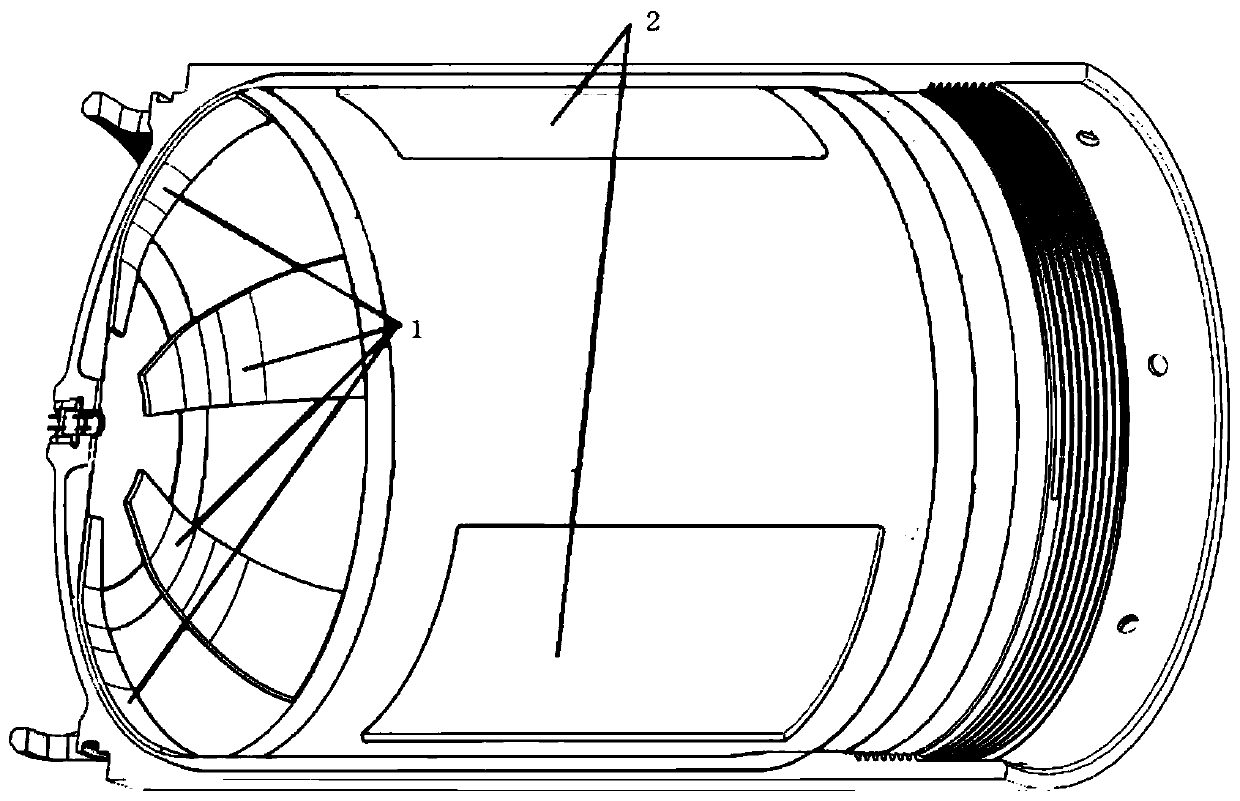

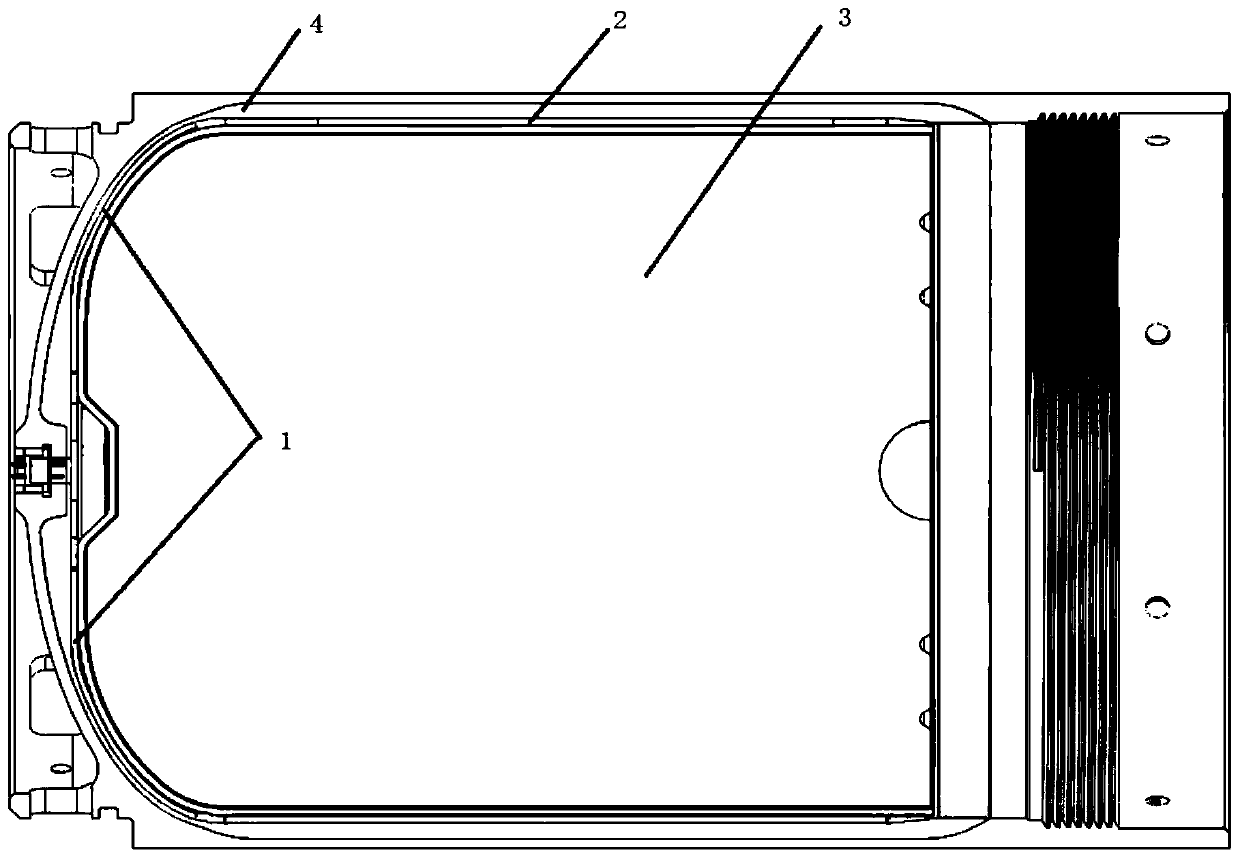

[0035] In this embodiment, the support device used for the solid rocket motor end combustion charge, the bottom support plate 1 and the side support plate 2 are EPDM plates, the inner surface of the side support plate 2 and the outer surface of the charge 3 There is a gap of 0.3mm between them, the cross section of the bottom support plate 1 is fan-shaped, and the thickness of the bottom support plate 1 is 1.3mm, and the supporting surface area of the bottom support plate 1 is 1200mm 2 , the bonding strength of the bottom support plate 1 is 2MPa; the cross section of the side support plate 2 is rectangular, and the length, width and thickness of the side support plate 2 are 100mm, 60mm and 1.5mm respectively; the combustion chamber is cylindrical, and the combustion chamber The diameter of the indoor surface is Ф142.2mm, and the diameter of the outer surface of the grain column 3 is Ф139mm.

[0036] Using the supporting device of this embodiment for the solid rocket motor en...

Embodiment 2

[0041] The difference from Embodiment 1 is that in this embodiment, a gap of 0.2mm is left between the inner surface of the side support plate 2 and the outer surface of the charge 3 in the supporting device for the solid rocket motor end combustion charge. The length, width and thickness of the support plate 2 are 100mm, 60mm and 1.2mm respectively.

[0042] (1) Determine that the proportion of the gap between the combustion inner surface 4 and the outer surface of the grain 3 is 62%, that is Into the formula It is calculated that the number of side support plates 2 installed is 4; the number of bottom support plates 1 installed is 4; where n is the number of side support plates, b is the width of the side support plates, δ is the thickness of the side support plates, and D is The diameter of the inner surface of the combustion chamber, d is the diameter of the outer surface of the grain, is the proportion of the space between the inner surface of the combustion chamber ...

Embodiment 3

[0046] The difference from Embodiment 1 is that this embodiment is used as a supporting device for solid rocket motor end-face combustion charges, and there is a gap of 0.1 mm between the inner surface of the side support plate 2 and the outer wall of the charge 3 . All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com