Double-insurance high-pressure ventilated reaction kettle with external reinforcing ribs

A double insurance and reinforcing rib technology, applied in the direction of pressure vessels used in chemical processes, can solve problems such as chemical reaction effects and explosions, and achieve the effects of enhancing strength, ensuring ventilation quality, and being easy to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

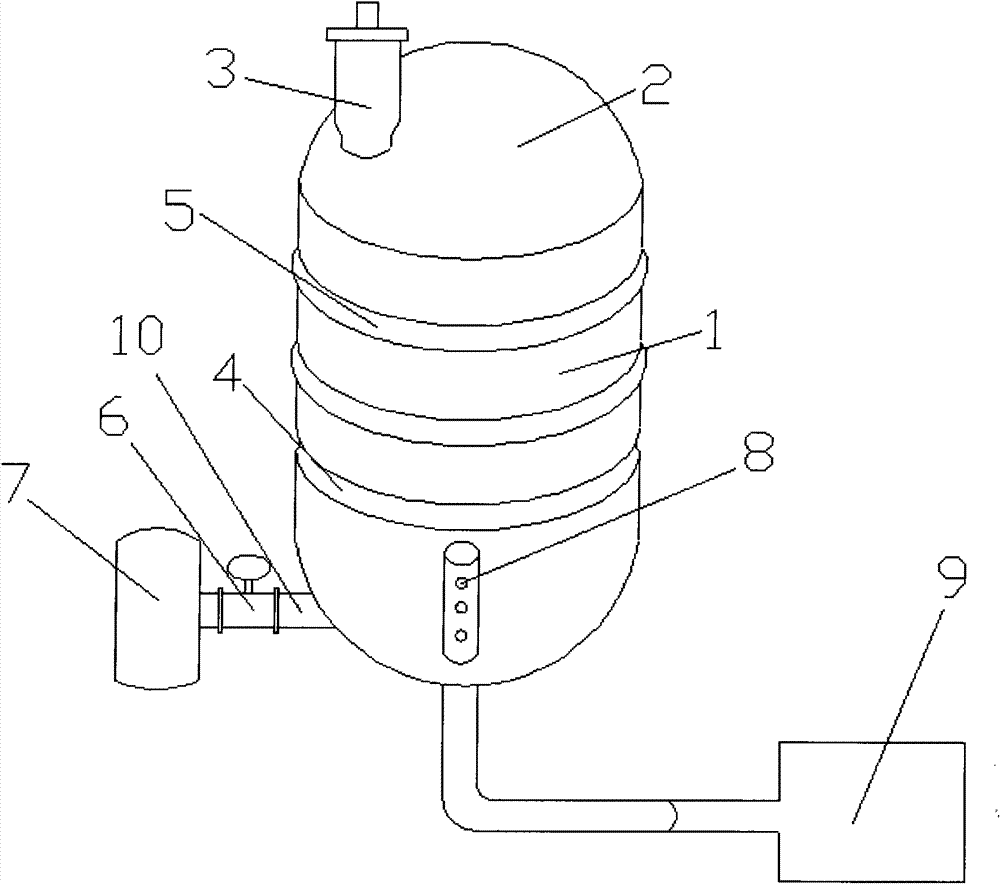

[0009] Such as figure 1 shown. A double-safety high-pressure ventilated reaction kettle with external reinforcing ribs, including a kettle body 1, a kettle cover 2, an explosion-proof valve 3 is installed on the kettle cover 2, and a plurality of annular grooves 4 surrounding the kettle body 1 are formed on the outer wall of the kettle body 1 , the annular groove 4 on the outer wall of the kettle body 1 is respectively provided with ring-shaped reinforcing ribs 5, the ring-shaped reinforcing ribs 5 are welded in the annular groove 4 of the kettle body 1, and the side of the kettle body 1 is provided with a pressure relief nozzle 10 for pressure relief. A valve 6 is installed on the nozzle 10, and a pressure relief storage tank 7 is arranged outside the kettle body 1. The air inlet of the pressure relief storage tank 7 communicates with the pressure relief nozzle 10 on the side of the kettle body 1 through the valve 6. An inflatable bubbling device is also installed. The infl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com