A high-speed common rail vane pump

A vane pump and common rail technology, which is applied to pumps, pump components, fuel injection pumps, etc., can solve problems affecting the oil delivery efficiency of vane pumps, unstable high-pressure environment for oil delivery in the stator, etc., achieve good low-speed performance and ensure stability performance, improve the efficiency of oil delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

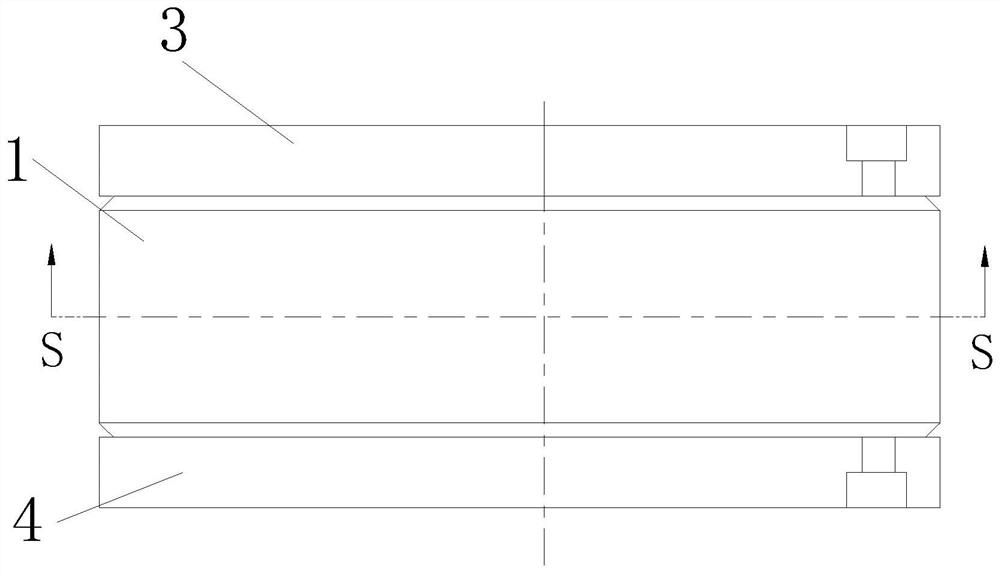

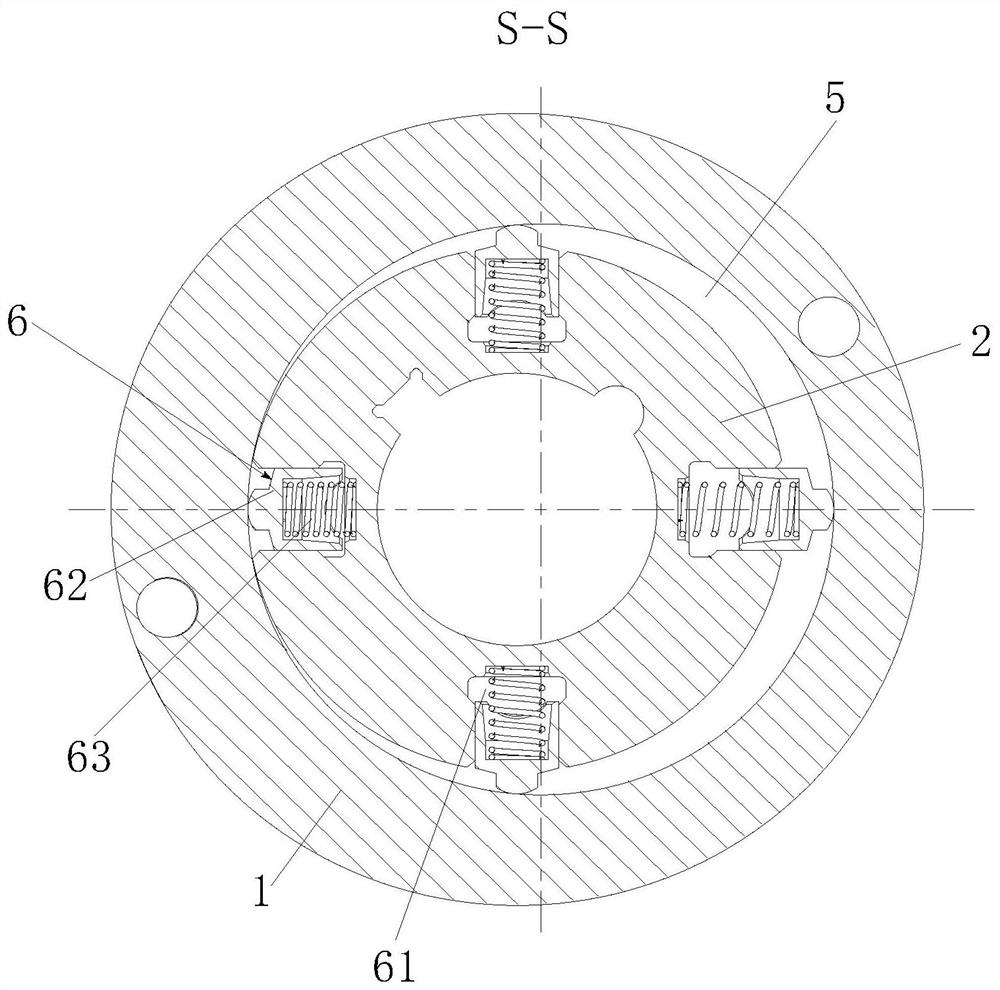

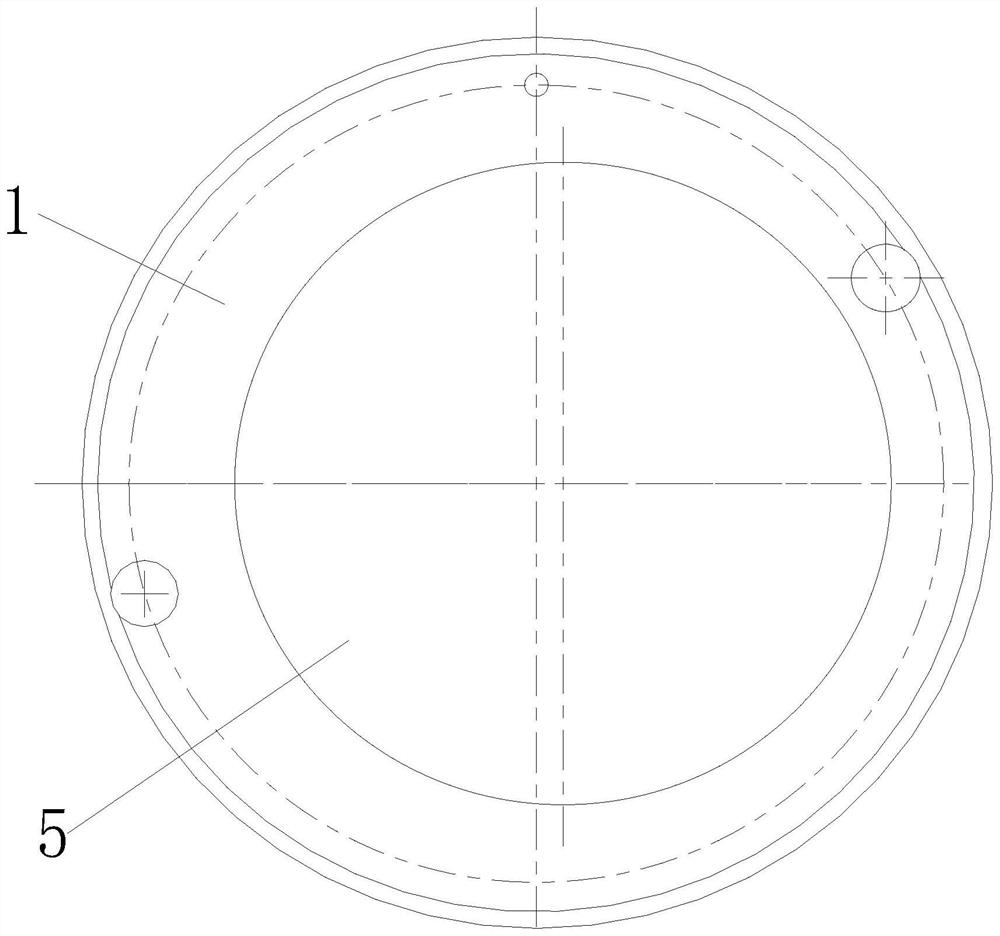

[0028] see Figure 1-9 , the present invention provides a technical solution: a high-speed common rail vane pump, including a stator 1, a rotor 2, an end cover 3 and a bottom plate 4, the rotor 2 is located in the eccentric hole 5 opened on the stator 1, and the outer wall of the rotor 2 There are four vane mechanisms 6 arranged circularly with the center of the rotor 2 as a reference, and the bottom plate 4 and the end cover 3 are symmetrically attached to the upper and lower surfaces of the stator 1 respectively.

[0029] The vane mechanism 6 includes a vane groove 61, a vane 62, a spring 63 and an arc bearing groove 64. The four vane grooves 61 are arranged in an annular arrangement on the outer side wall of the rotor 2. The vane 62 is inserted into the vane groove 61, and the arc The shape bearing groove 64 is offered at the side of the blade 62 near the bottom wall of the blade groove 61, and the bottom wall of the spring groove 65 provided in the middle of the arc bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com