Compressor and air conditioner with compressor

A compressor and body technology, applied in compressors, machines/engines, refrigerators, etc., can solve the problems of compressor reliability hazards, high and low pressure gas leakage, sliding vanes and rollers detachment, etc., to solve the problem of clicking noise , to ensure reliability and reduce the effect of liquid hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described in conjunction with the following examples.

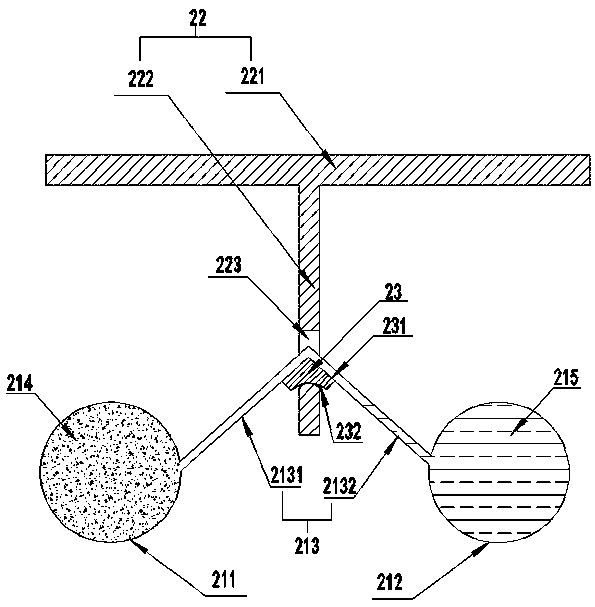

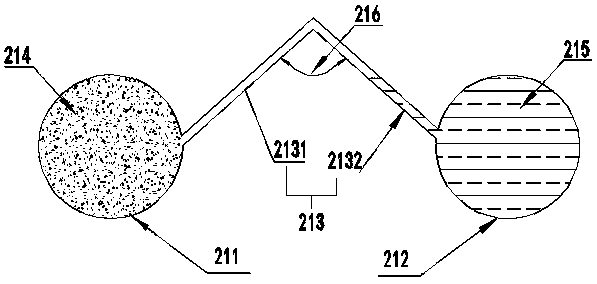

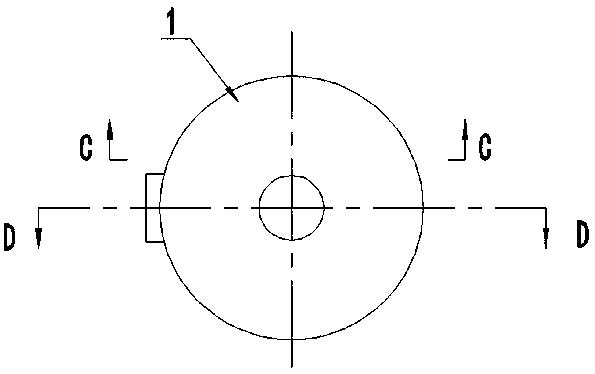

[0026] Such as Figure 1-8 As shown, the embodiment of the present invention provides a compressor, which includes a compressor body 1. A liquid separator 2 for absorbing refrigerant inside the compressor body 1 is fixed inside the compressor body 1. The liquid separator 2 includes a The hot heat radiation assembly 21 and the limit piece 22 used to limit the inclination angle of the heat radiation assembly 21 in the vertical direction, the heat radiation assembly 21 is rotatably connected to the limit piece 22 through the connecting piece 23. The liquid separator 2 that absorbs the refrigerant inside the compressor body 1, so that when there is a certain amount of refrigerant inside the compressor, all the liquid refrigerant inside the compressor can be absorbed through the heat release component 21, so as to avoid the compressor from being converted by the refrigerant when it sucks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com