A device and method for measuring the verticality of a deep hole in a tube sheet

A measurement method and a technology of a measurement device, which are applied in the direction of a measurement device, a mechanical measurement device, and a mechanical device, can solve the problems of restricting the progress of manufacturing and inspection of heat exchangers, the inability to complete inspections independently, and the large ratio of hole depth to hole diameter. Achieve the effects of avoiding a large number of unqualified verticality of deep holes, less difficulty in measurement implementation, and shorter detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

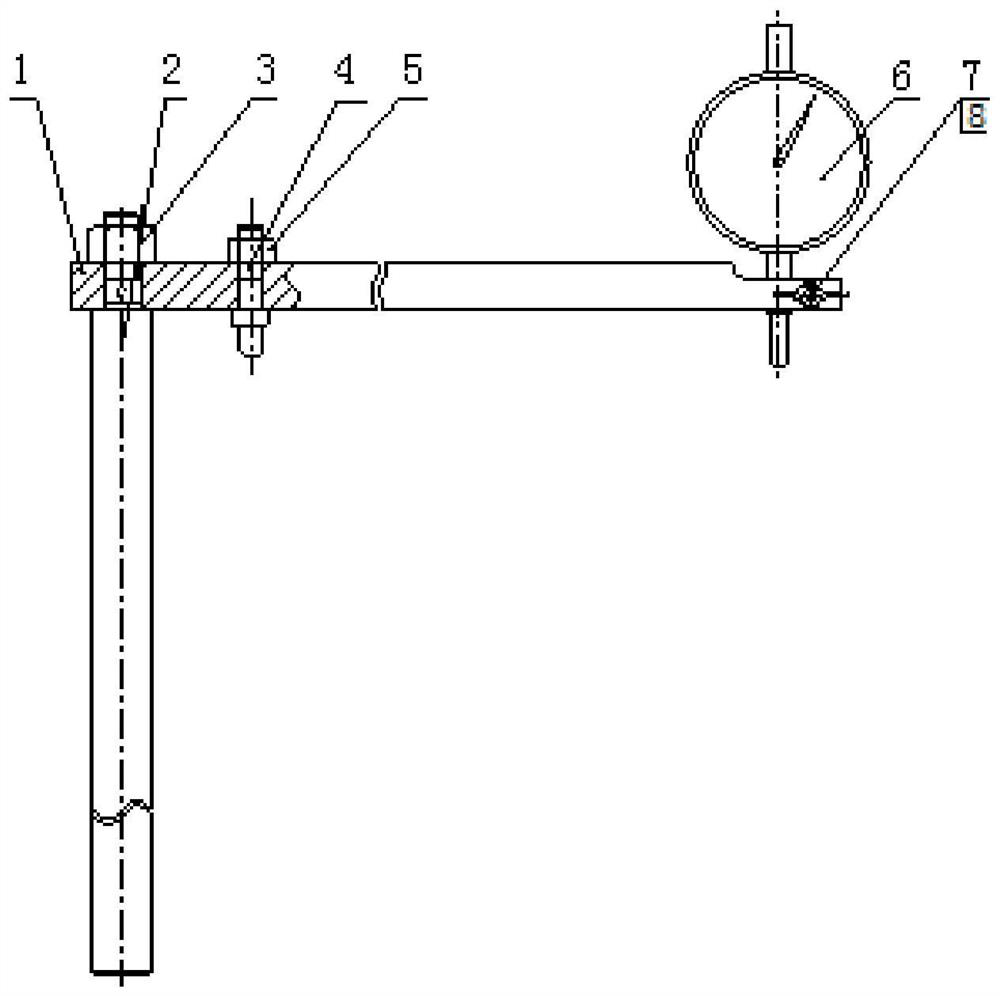

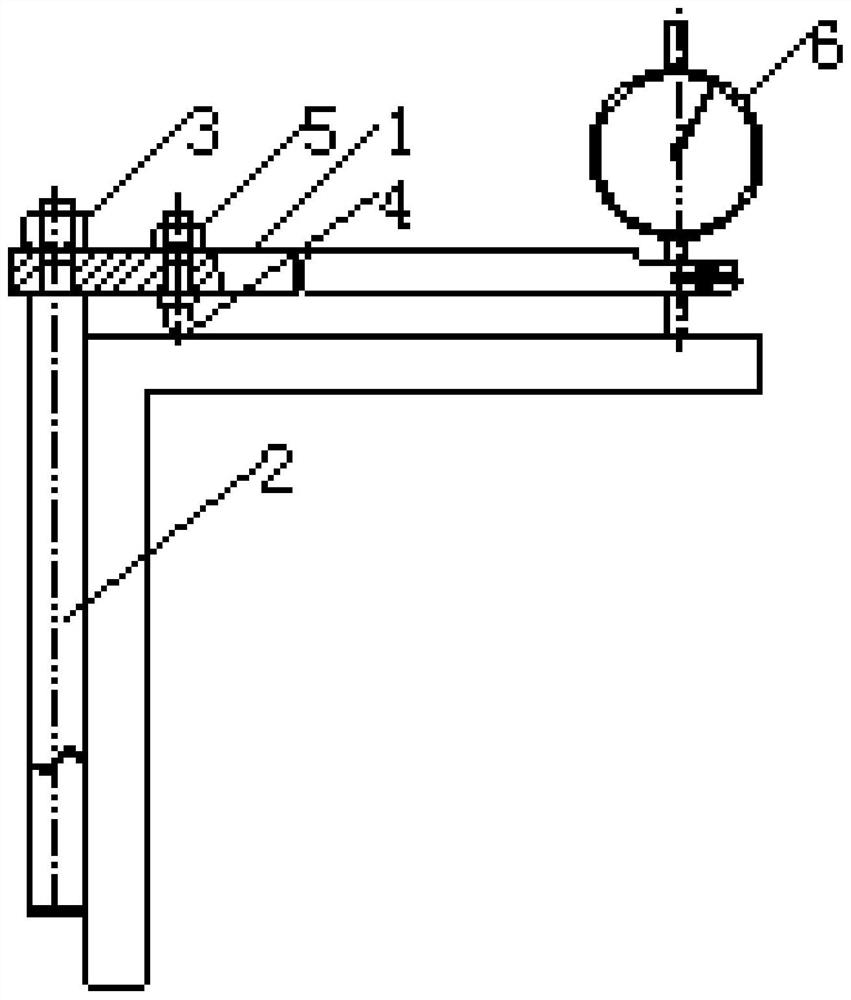

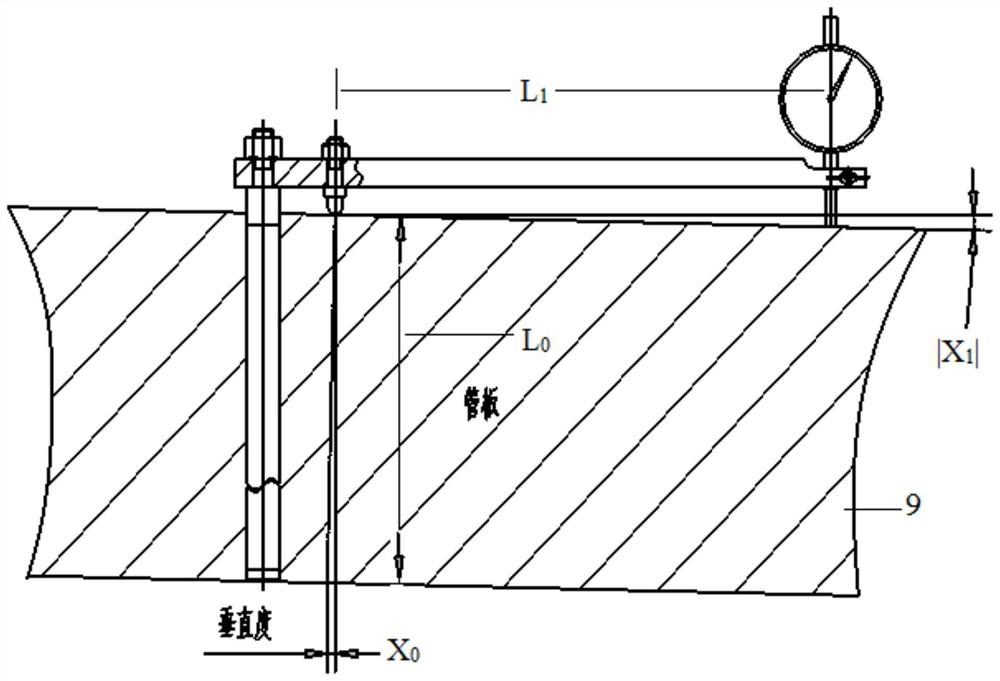

[0046] The present invention will be further described in detail through the drawings and examples below. Through these descriptions, the features and advantages of the present invention will become more apparent.

[0047] The word "exemplary" is used exclusively herein to mean "serving as an example, embodiment, or illustration." Any embodiment described herein as "exemplary" is not necessarily to be construed as superior or better than other embodiments. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

[0048] The deep hole of the tube plate of nuclear power heat exchanger is an important manufacturing process of the heat exchanger. The tube plate hole is the weak link of the heat exchanger, especially the verticality of the tube hole, which directly affects the size of the secondary side hole bridge, which will directly affect the to the quality of the heat exchanger. Therefore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com