Acquisition method of laser resistance trimming scheme, laser resistance trimming scheme and chip resistor

A technology of laser resistance adjustment and acquisition method, which is applied to non-adjustable metal resistors, resistors, resistance manufacturing and other directions, can solve the problems of low resistance precision and low yield, and achieves the improvement of controllability, precision and yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The method for obtaining a laser resistance trimming solution provided in this embodiment is used to obtain a laser resistance trimming method.

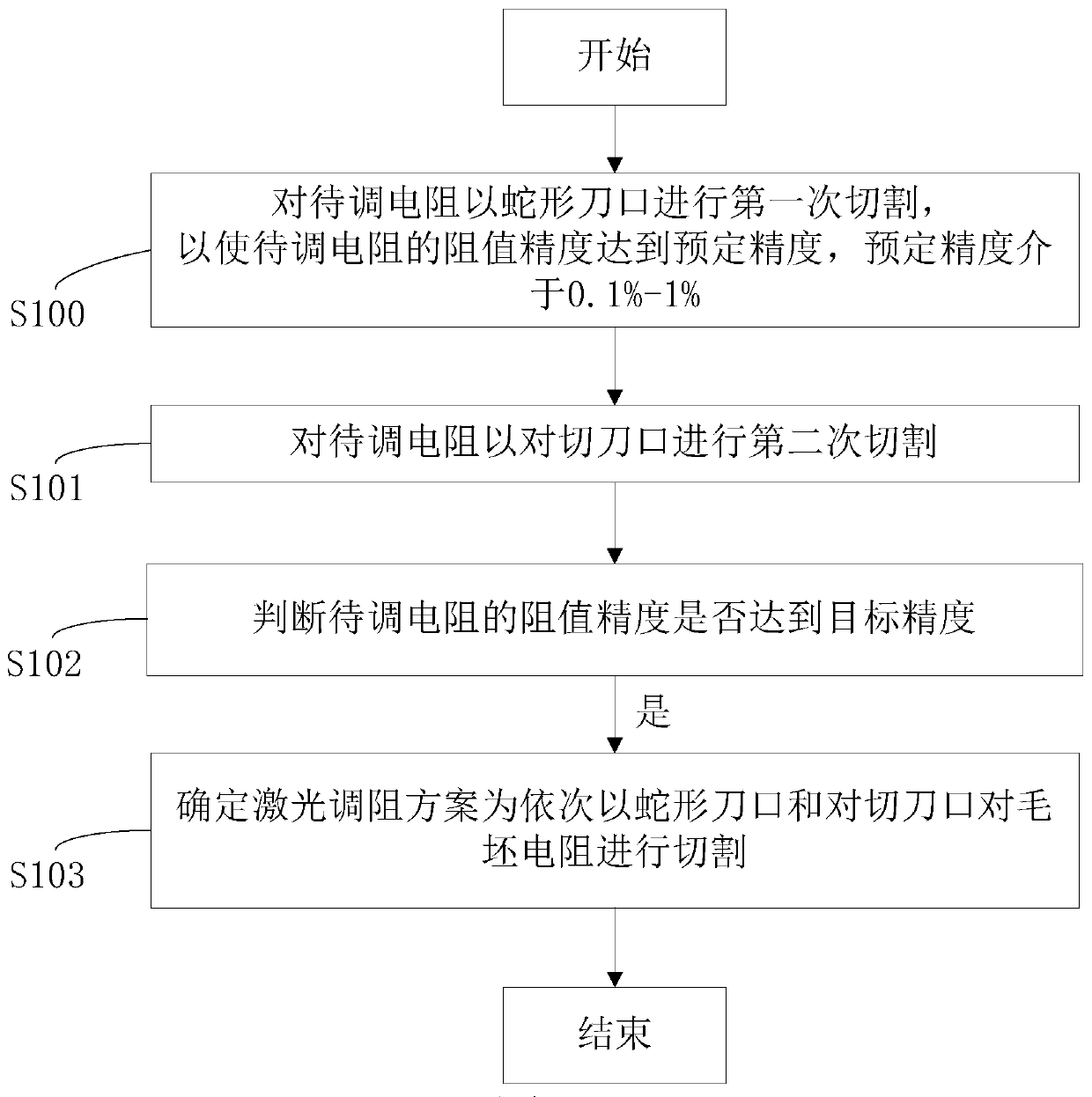

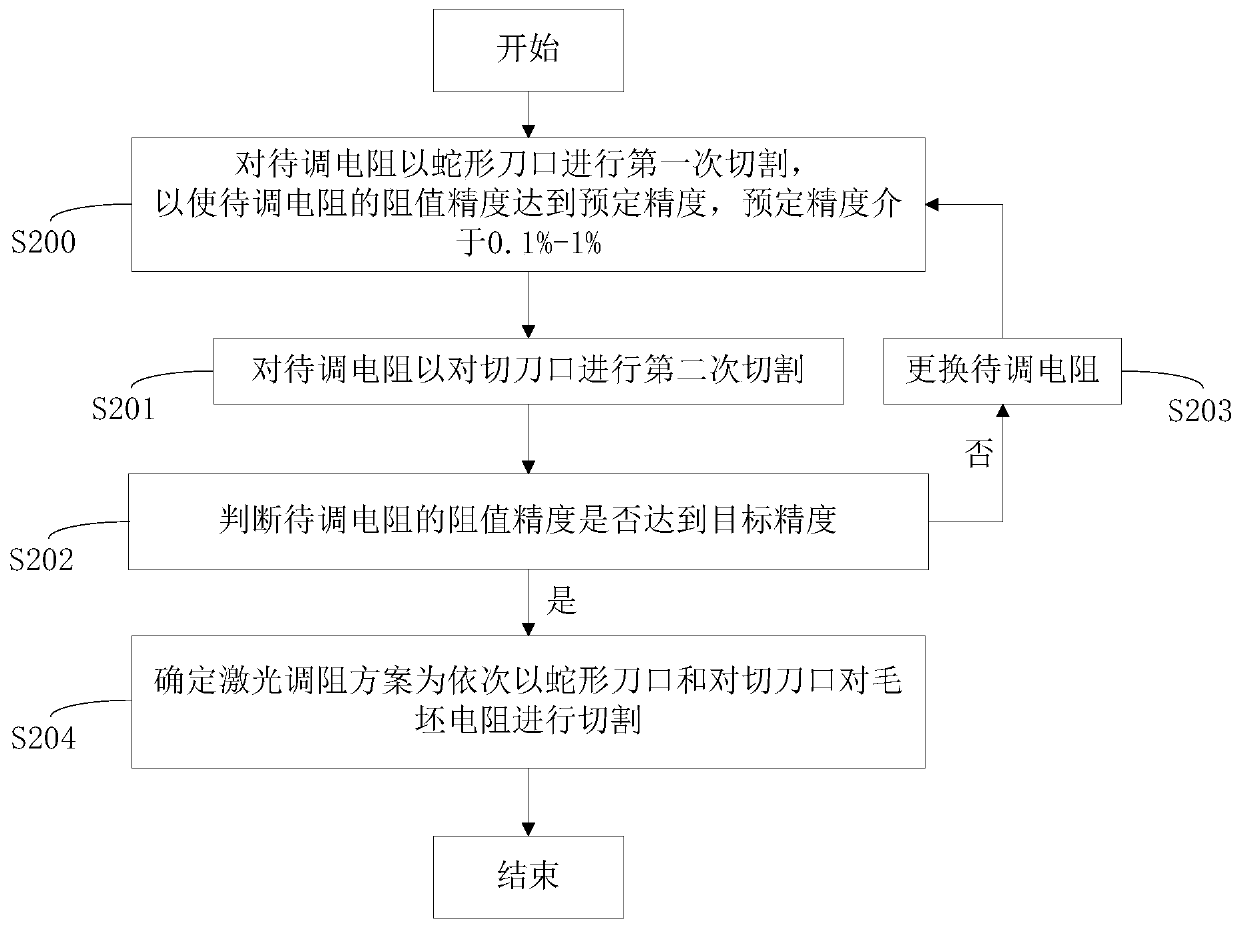

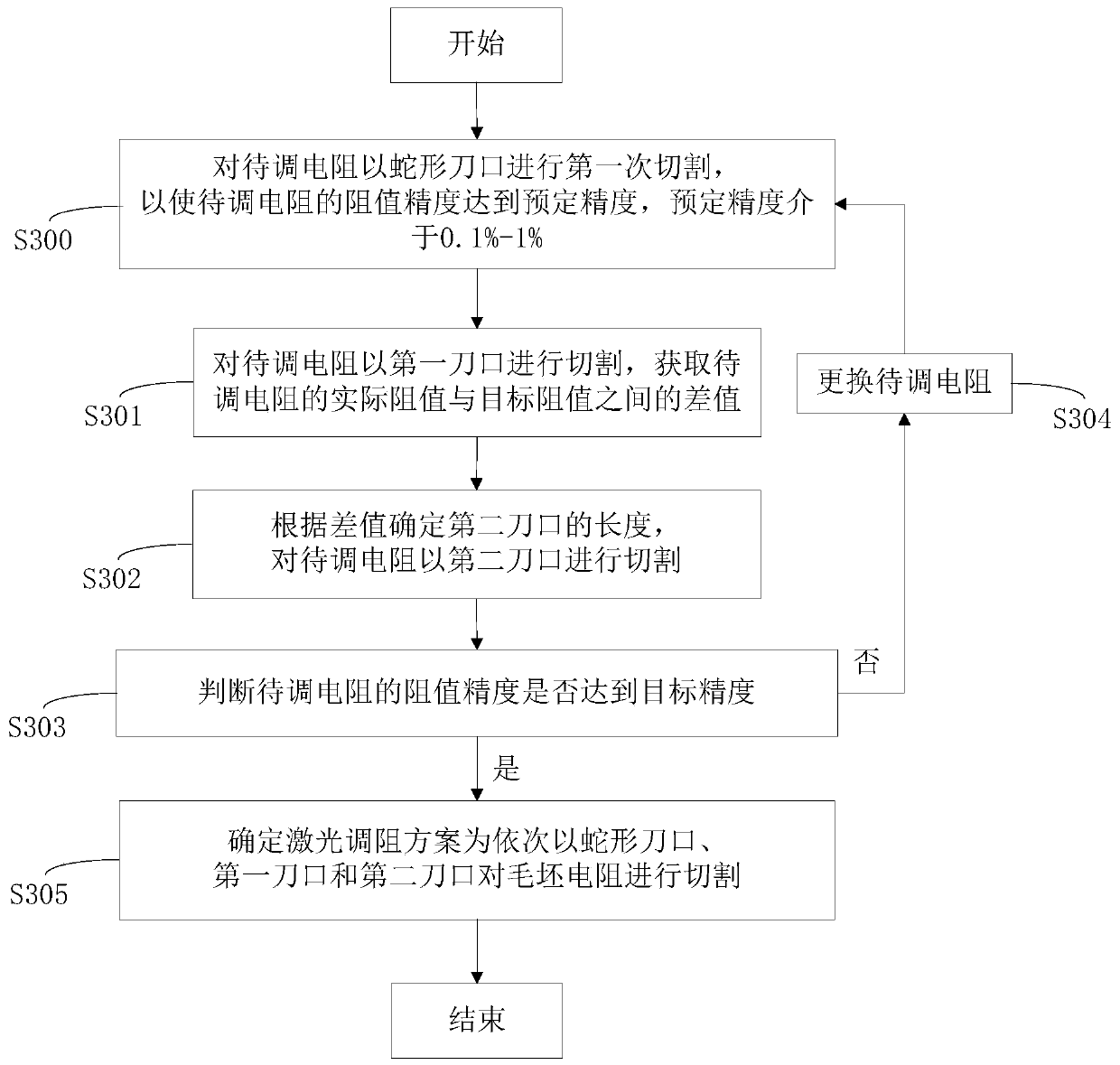

[0059] see figure 1 As shown, the method for obtaining the laser resistance trimming solution provided in this embodiment includes the following steps:

[0060] S100, cut the resistance to be adjusted for the first time with a serpentine knife edge, so that the resistance accuracy of the resistance to be adjusted can reach the predetermined accuracy, and the value range of the predetermined accuracy is 0.1%-1%;

[0061] S101, adjust the resistance to perform a second cut on the cutting edge;

[0062] S102, judging whether the resistance precision of the resistor to be adjusted reaches the target precision;

[0063] S103, if the resistance accuracy of the resistor to be adjusted reaches the target accuracy, determine the laser resistance adjustment solution as cutting the blank resistor with a serpentine edge and a counter-cu...

Embodiment 2

[0126] Embodiment 2 provides a laser resistance trimming solution, which includes the acquisition method of the laser resistance trimming solution in Embodiment 1, and the technical features of the laser resistance trimming solution acquisition method disclosed in Embodiment 1 are also applicable to this implementation For example, the technical features of the method for obtaining the disclosed laser resistance trimming solution in Embodiment 1 will not be described repeatedly.

[0127] The laser resistance trimming solution provided in this embodiment is obtained by the method for obtaining the laser resistance trimming solution provided in Embodiment 1.

[0128] Specifically, the laser resistance trimming solution includes the following steps:

[0129] S700, for the first cutting of the blank resistor with a snake-shaped knife edge, so that the resistance precision of the resistor to be adjusted can reach the predetermined precision;

[0130] S701, performing a second cut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com