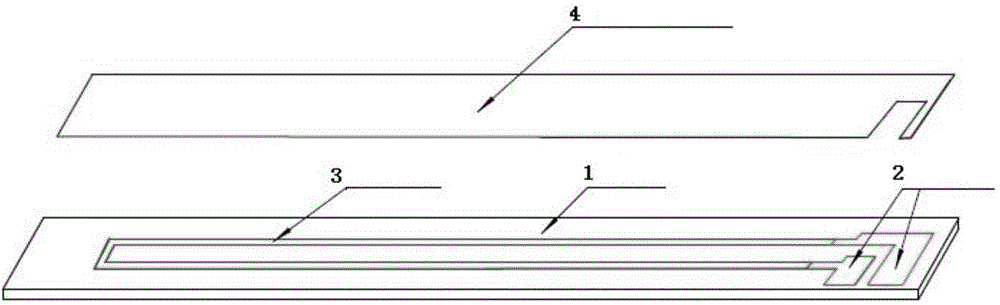

Ceramic heating sheet and manufacturing method thereof

A technology of ceramic heating sheet and heating wire, applied in heating element materials, ohmic resistance heating, electric heating devices, etc., can solve the problems of short service life and large resistance change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

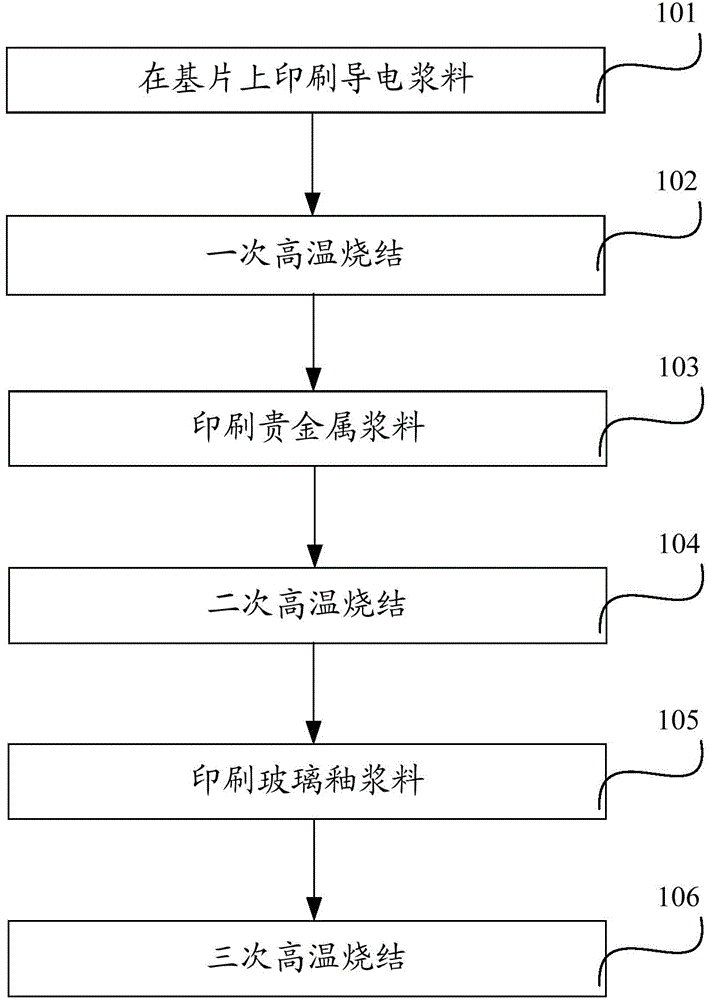

[0022] Correspondingly, the present invention also provides a method for preparing a ceramic heating chip, comprising the following steps:

[0023] 101: printing conductive paste on the ceramic substrate;

[0024] 102: One-time high-temperature sintering;

[0025] 103: printing precious metal paste;

[0026] 104: secondary high temperature sintering;

[0027] 105: printing glass glaze paste;

[0028] 106: three times high temperature sintering,

[0029] Obtain ceramic heating plate, described noble metal slurry comprises following composition: P d : 35wt% ~ 85wt%; A g : 10wt% ~ 40wt%; S i o 2 : 1wt% ~ 4wt%; Al 2 o 3 : 2wt% ~ 5wt%; M n o 2 : 1wt% ~ 6wt%; CaO: 0 ~ 6wt%; the balance is cellulose and terpineol. As a preferred version, the noble metal slurry includes the following components: P d : 40wt% ~ 80wt%; A g : 20wt% ~ 30wt%; S i o 2 : 2wt% ~ 3wt%; Al 2 o 3 : 3wt% ~ 4wt%; M n o 2 : 2wt% ~ 5wt%; CaO: 1wt% ~ 5wt%; the balance is cellulose and terpineol.

[...

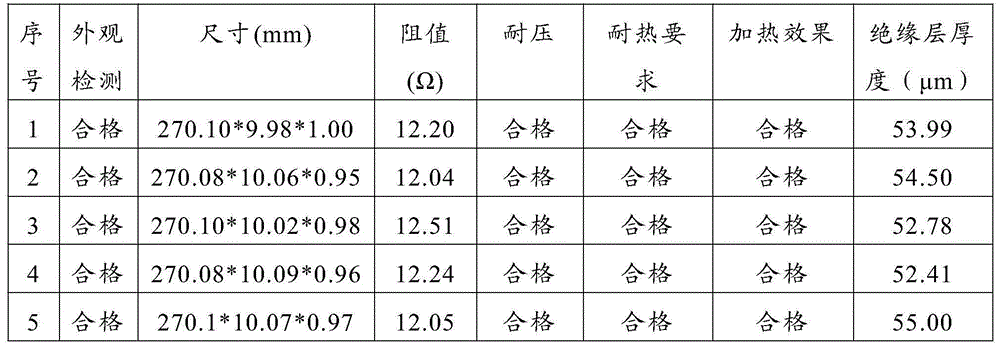

Embodiment 1

[0040] Step 101: Printing conductive paste on the ceramic substrate, including: photo master plate, photosensitive, developing, fixing, printing, leveling, drying, sintering;

[0041] Step 102: primary high-temperature sintering, the temperature of the primary high-temperature sintering is 800° C., and the holding time is 5 minutes;

[0042] Step 103: printing precious metal paste, including: photo master plate, photosensitive, developing, fixing, printing, leveling, drying, sintering, the precious metal paste includes the following components: P d : 50wt%; A g : 30wt%; S i o 2 : 3wt%; Al 2 o 3 : 4wt%; M n o 2 : 5wt%; CaO: 5wt%, the balance is cellulose and terpineol;

[0043] Step 104: secondary high-temperature sintering, the temperature of the secondary high-temperature sintering is 850° C., and the holding time is 10 minutes;

[0044] Step 105: printing glass glaze paste, including: photographic master plate, photosensitive, developing, fixing, printing, leveling, ...

Embodiment 2

[0064] Step 101: Printing conductive paste on the ceramic substrate, including: photo master plate, photosensitive, developing, fixing, printing, leveling, drying, sintering;

[0065] Step 102: primary high-temperature sintering, the temperature of the primary high-temperature sintering is 800° C., and the holding time is 5 minutes;

[0066] Step 103: printing precious metal paste, including: photo master plate, photosensitive, developing, fixing, printing, leveling, drying, sintering, the precious metal paste includes the following components: P d : 60wt%; A g : 25wt%; S i o 2 : 2wt%; Al 2 o 3 : 2wt%; M n o 2 : 2wt%; CaO: 2wt%, the balance is cellulose and terpineol;

[0067] Step 104: secondary high-temperature sintering, the temperature of the secondary high-temperature sintering is 850° C., and the holding time is 10 minutes;

[0068] Step 105: printing glass glaze paste, including: photographic master plate, photosensitive, developing, fixing, printing, leveling, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com