Photosensitive thin film transistor and preparation method thereof

A photosensitive thin film and transistor technology, which is applied in the direction of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

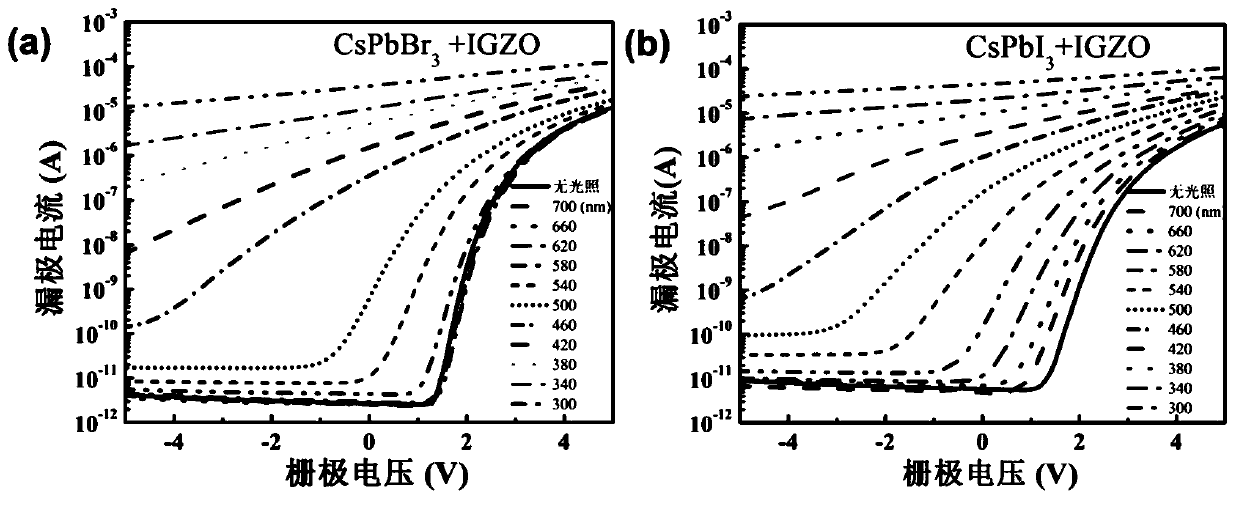

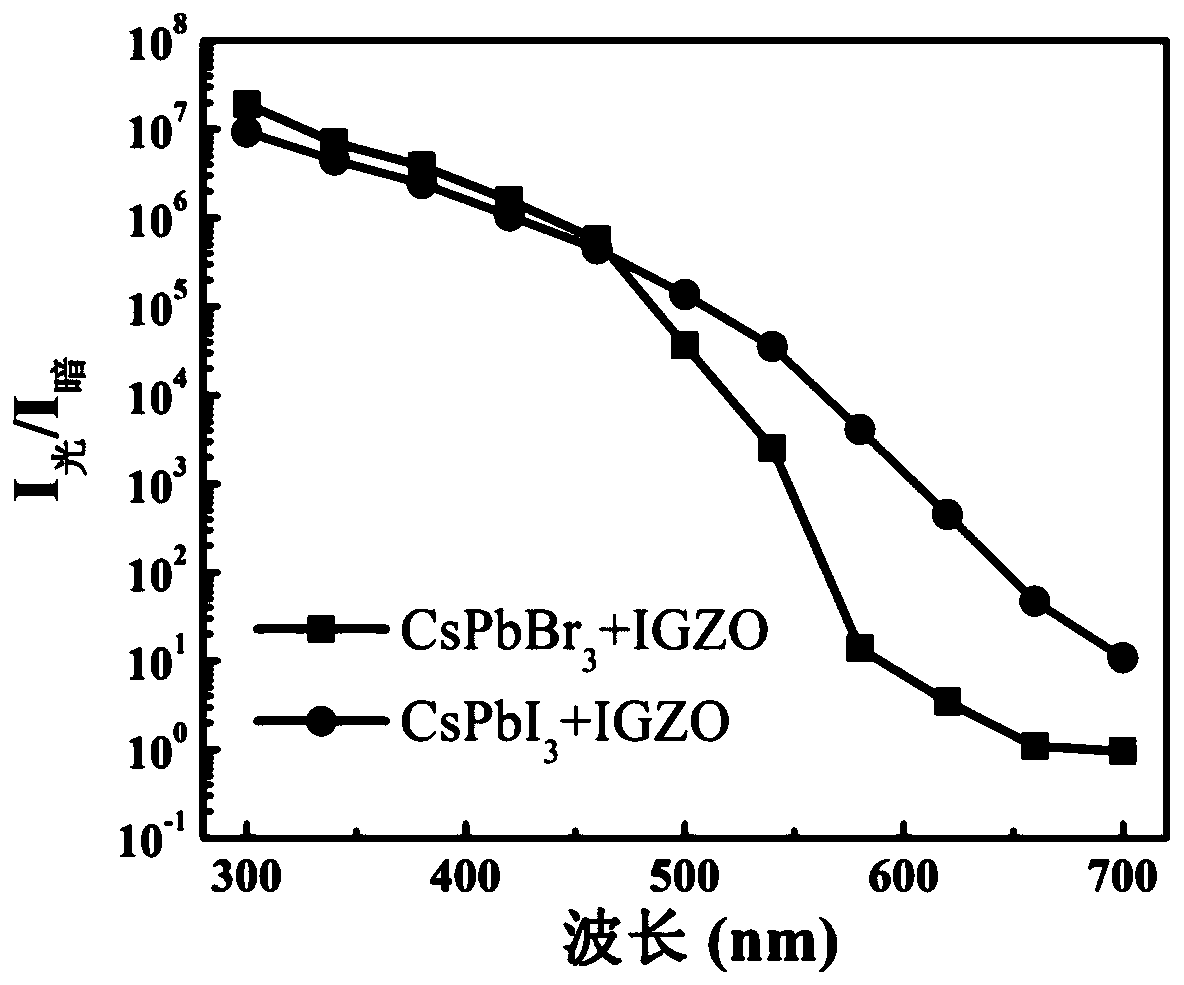

[0039] The photosensitive material used in this embodiment is CsPbBr 3 quantum dots.

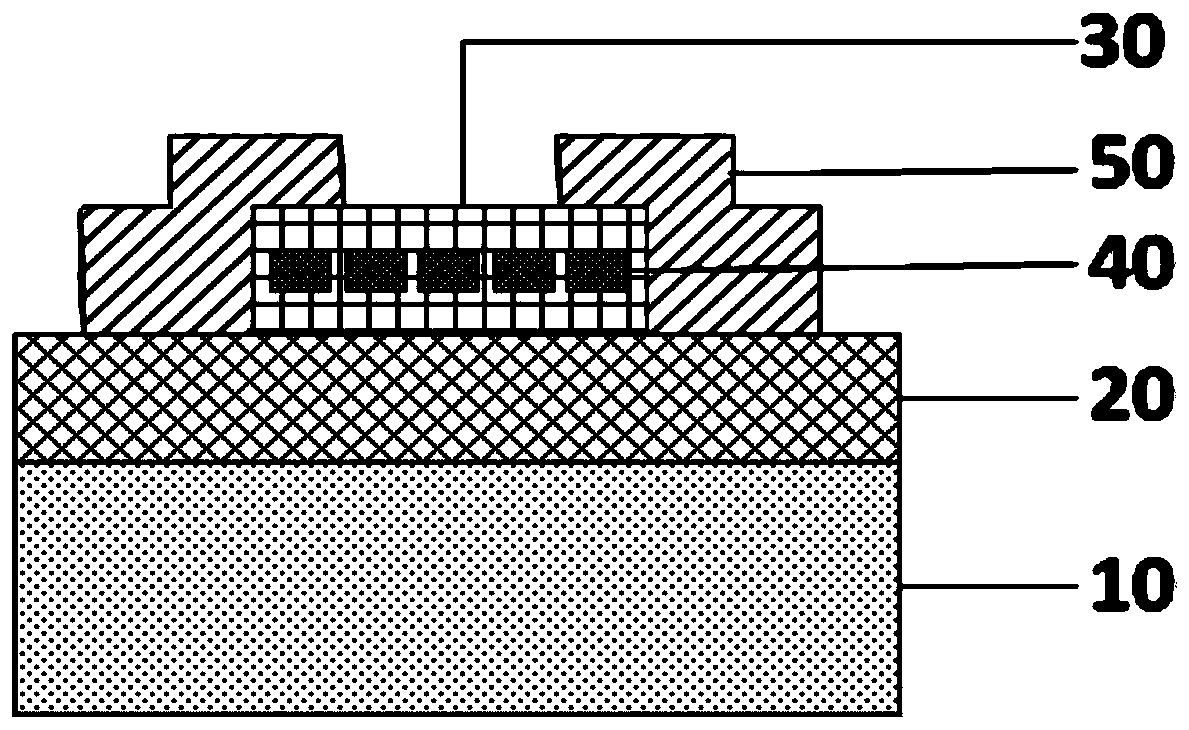

[0040] Such as figure 1 As shown, the photosensitive thin film transistor provided by the present invention has a structure from bottom to top: back gate electrode 10, gate dielectric layer 20, conductive channel 30, and source and drain electrodes 50, wherein perovskite quantum dots 40 are used as photosensitive materials , located in the middle of the conducting channel. Concrete preparation process is as follows:

[0041] (1) The back gate electrode 10 is made of heavily doped p-type silicon with a resistivity of <0.005 Ω•cm, and is cleaned with acetone, isopropanol, and deionized water in sequence before use.

[0042] (2) The gate dielectric layer 20 is made of Al 2 o 3 Thin film, oxygen source is oxygen plasma, aluminum source is trimethylaluminum (TMA), TMA temperature, oxygen gas flow rate and plasma generation power are set to 18 ℃, 150 sccm and 2500 W, respectively, growth tem...

Embodiment 2

[0047] The photosensitive material that present embodiment adopts is CsPbI 3 quantum dots. The specific preparation process is:

[0048] (1) The back gate electrode 10 is made of heavily doped p-type silicon with a resistivity of <0.005 Ω•cm, and is cleaned with acetone, isopropanol, and deionized water in sequence before use.

[0049] (2) The gate dielectric layer 20 is made of Al 2 o 3 For thin films, the oxygen source is oxygen plasma, the aluminum source is TMA, the TMA temperature, oxygen gas flow rate and plasma generation power are set to 18 ℃, 150 sccm and 2500 W, respectively, the growth temperature is 30 ℃, and the growth thickness is 40 nm.

[0050] (3) The conductive channel 30 is an amorphous IGZO film prepared by magnetron sputtering. The selected target is an IGZO target with an atomic ratio of In:Ga:Zn:O = 1:1:1:4. The total growth The thickness was 40 nm, and the working pressure, RF power, argon and oxygen gas flows were set to 0.88 Pa, 110 W, 48 and 2 sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap