Adjustable horizontal-pouring buttress template provided with magnetic jig

An adjustable and formwork technology, which is applied in the direction of mold fixing devices, mold auxiliary parts, ceramic molding machines, etc., can solve the problems of difficult fixation, time-consuming and labor-consuming, heavy steel formwork, etc., to achieve easy installation and disassembly, and convenient Reusable, versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

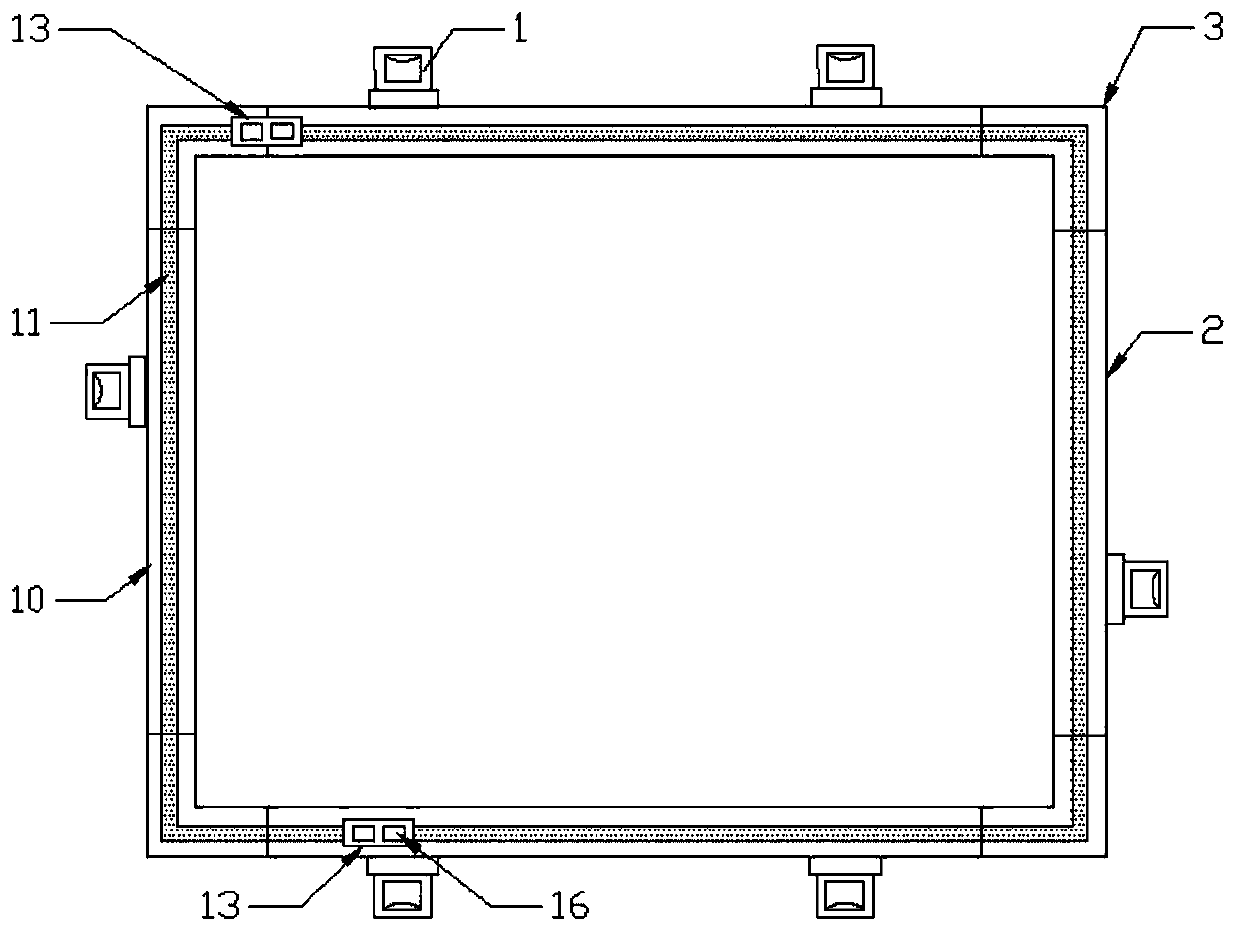

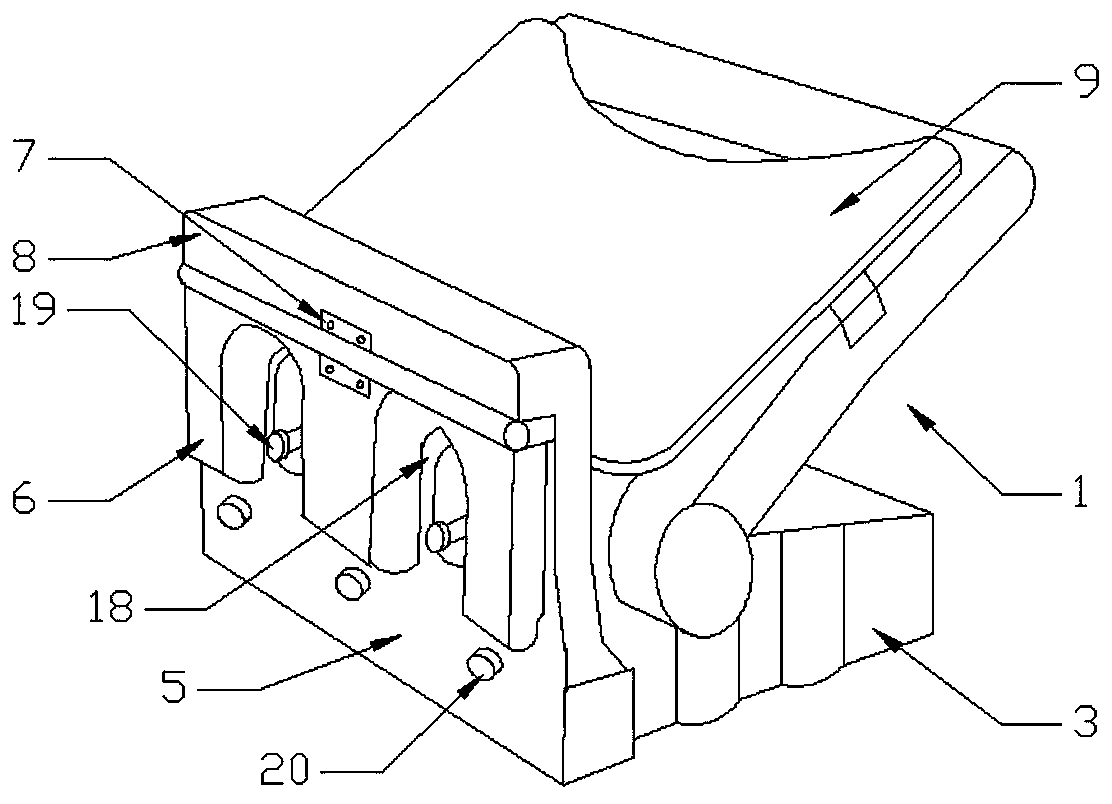

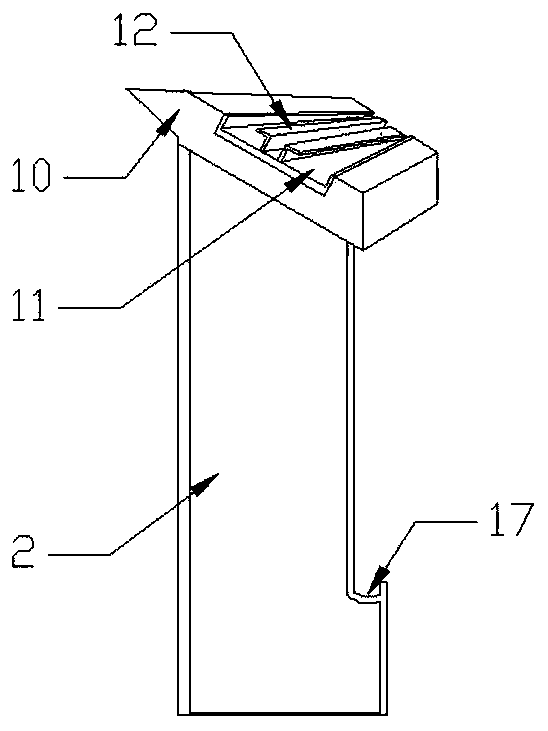

[0023] According to the different requirements for the length and width of the material, select different numbers of the first formwork 2, place the first formwork 2 on the iron workbench, place an appropriate number of connectors 13 on the first formwork 2, take four The second formwork 3 is distributed at the four corners. Move and adjust the first formwork 2 and the second formwork 3 so that they are spliced into a rectangular ring with a cross section, and the connector 13 is moved to the connection between the corresponding formworks. Parts 16 are respectively located on two adjacent templates, and when the limiter 16 is closed, the block 21 on the rotating shaft 15 just touches the upper surface of the engaging mechanism 12. At this time, the connecting part 13 cannot be placed on the first template 2 or the second template. The top of the template 3 moves to fix the relative position between the first template 2 and the second template 3; place an appropriate number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com