Transmission device capable of adjusting tension degree

A transmission device and tension technology, which is applied in the field of transmission devices with adjustable tension, can solve the problems of difficult adjustment of the conveyor belt, and achieve the effects of ensuring safety, prolonging service life and reducing replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

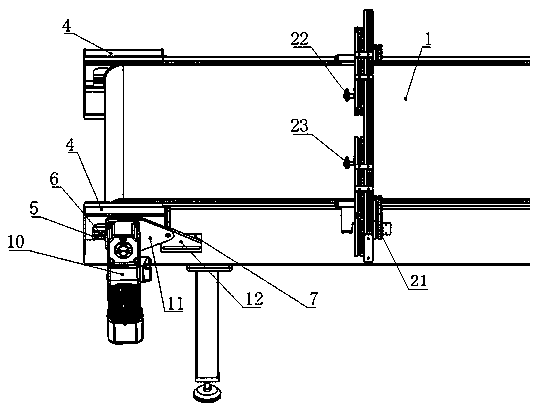

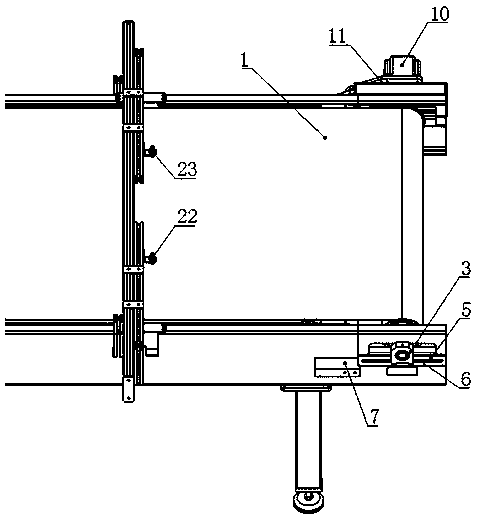

[0030] like Figure 1-2 As shown, a tension-adjustable transmission device includes a belt 1, a roller shaft 2 that drives the belt 1 to rotate, and a support unit. Both ends of the roller shaft 2 are provided with symmetrical bearing seats 3 and adjustment seats 4. , the bearing seat 3 is installed on the adjustment hole or the adjustment groove 6 of the adjustment seat 4, the adjustment direction of the adjustment hole or the adjustment groove 6 is consistent with the rotatable direction of the belt 1, the adjustment seat 4 is fixedly installed on the support unit, the bearing seat 3 can Slide along the adjustment hole or the adjustment groove 6 to drive the roller shaft 2 to move, and then achieve the purpose of adjusting the tightness of the belt 1.

Embodiment 2

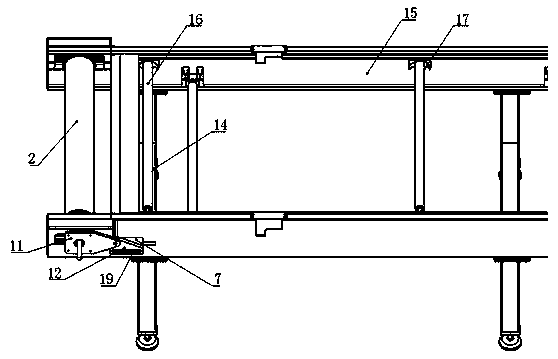

[0032] like Figure 4 As shown, on the basis of the structure of Embodiment 1, in order to better adjust the horizontal movement of the roller shaft 2, a fixed seat 7 is provided in the sliding direction of the bearing seat 3, and an adjusting threaded hole 8 and Matching adjustment screw 9, the installation direction of the adjustment screw 9 is consistent with the adjustment hole of the adjustment seat 4 or the direction of the adjustment groove 6, and one end of the adjustment screw 9 is against the bearing seat 3, and cooperates to push the bearing seat 3 along the adjustment hole of the adjustment seat 4 Or the adjustment groove 6 slips, so as to realize the movement of the roller shaft 2 and achieve the purpose of assisting in adjusting the tightness of the belt 1 .

[0033] like Figure 5 As shown, a bearing seat cover plate 4 is also provided outside the bearing seat 3 .

Embodiment 3

[0035] like Figure 3-4 As shown, on the basis of the structure of Embodiment 2, when the roller shaft 2 is used as the driving shaft, one end of the driving shaft is connected to the driving motor 10 through the bearing seat 3 . Preferably, in order to prevent the driving motor 10 from rotating during operation, a torsion arm plate 11 is also provided, one end of the torsion arm plate 11 is fixedly connected to the driving motor 10 , and the other end is slidably connected to the supporting unit or the fixing seat 7 .

[0036] Further, the fixing seat 7 is provided with a connecting plate 12 for connecting with the torsion arm plate 11 , and the connecting plate 12 is provided with a slide groove 13 which facilitates the movement of the torsion arm plate 11 . When the position of the driving shaft needs to be adjusted, the bearing seat 3 drives the torsion arm plate 11 to move, and at the same time, the torsion arm plate 11 is limited by the connecting plate 12 to prevent the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com