Synchronous operation device for plastic profile cutting platform

A technology for cutting platforms and plastic profiles, which is applied in metal processing and other directions, can solve the problems of large precision error of fixed-length cutting, poor quality of cutting section, fluctuation of compressed air pressure, etc., and achieves simple and convenient maintenance, low cost and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

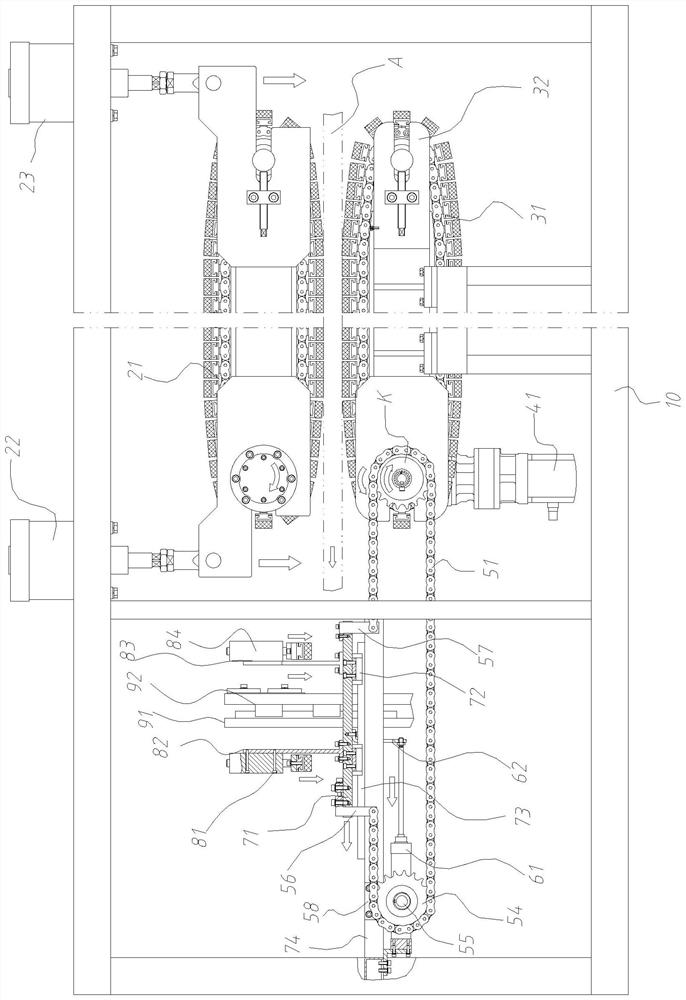

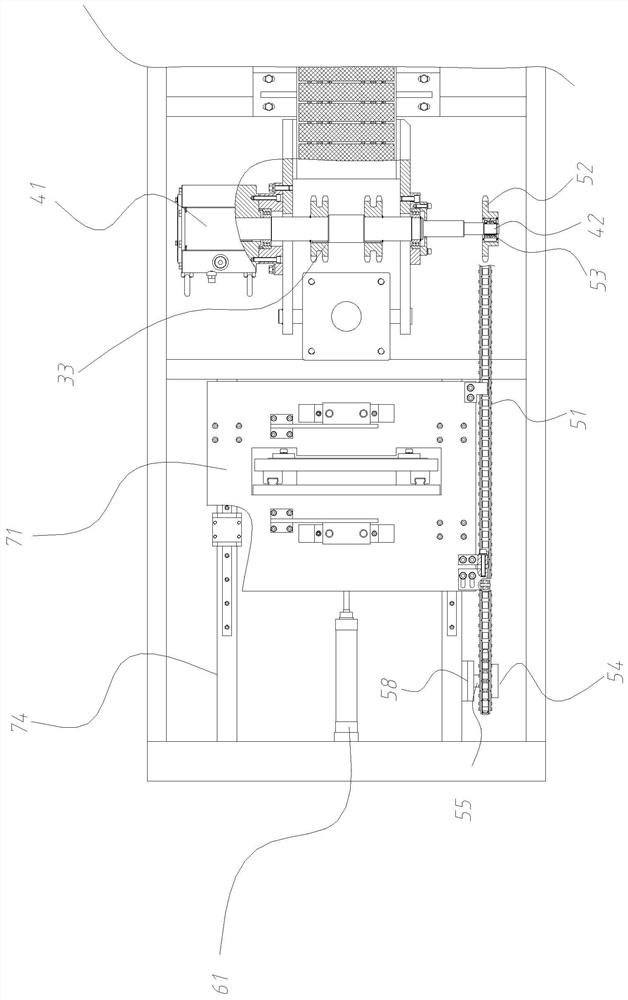

[0040] Such as Figure 1-3Shown: a synchronous operation device for a plastic profile cutting platform, including a conveying module and a cutting module arranged sequentially along the plastic profile A cutting production process; the conveying module is installed on the production line support 10 to carry out Conveying; the cutting module is installed on the production line support 10, and docked with the conveying module to cut the plastic profile A; it is characterized in that it also includes a synchronous operation module; one end of the synchronous operation module is connected to the transportation The module is connected, and the other end is connected with the cutting module for synchronous operation of the conveying module and the cutting module.

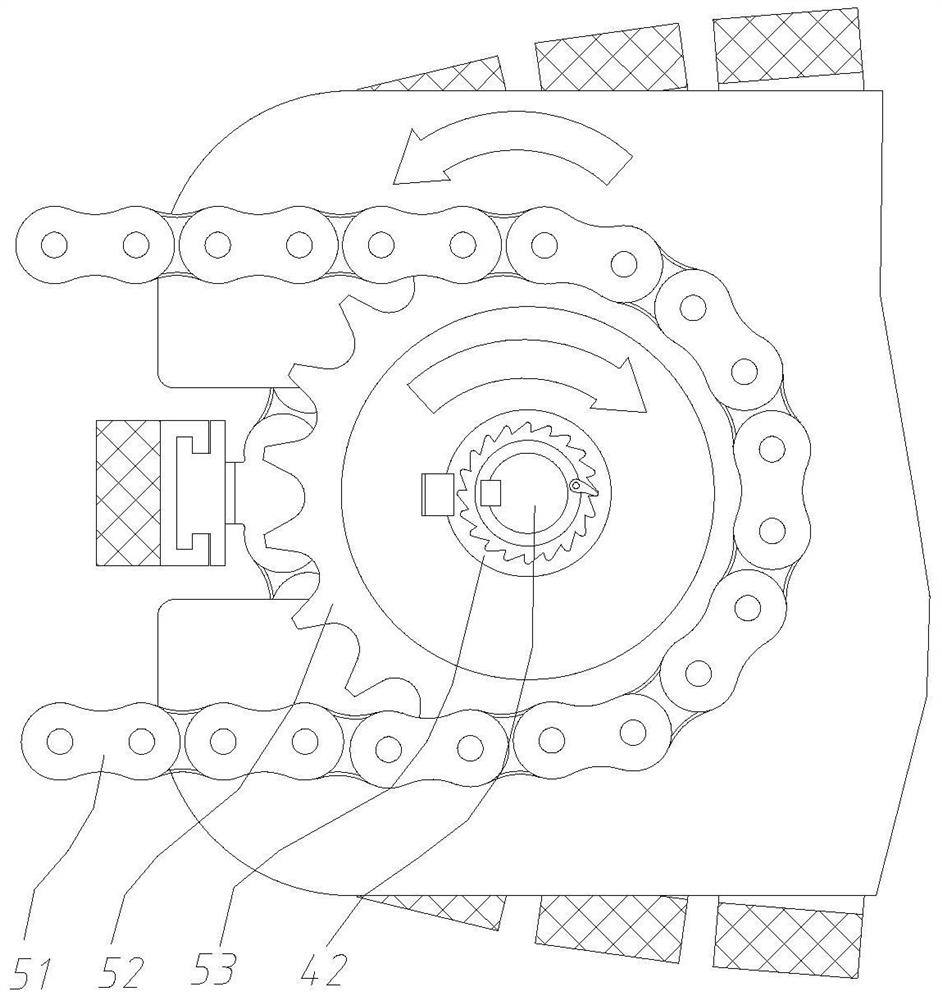

[0041] The conveying module includes a lower conveying crawler belt 31, a conveying platform 32, a driving connection wheel 33, a reduction motor 41 and a driving shaft 42 constituting a rotating shaft. The drive shaft 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com