A kind of pectin esterase and its preparation method and application

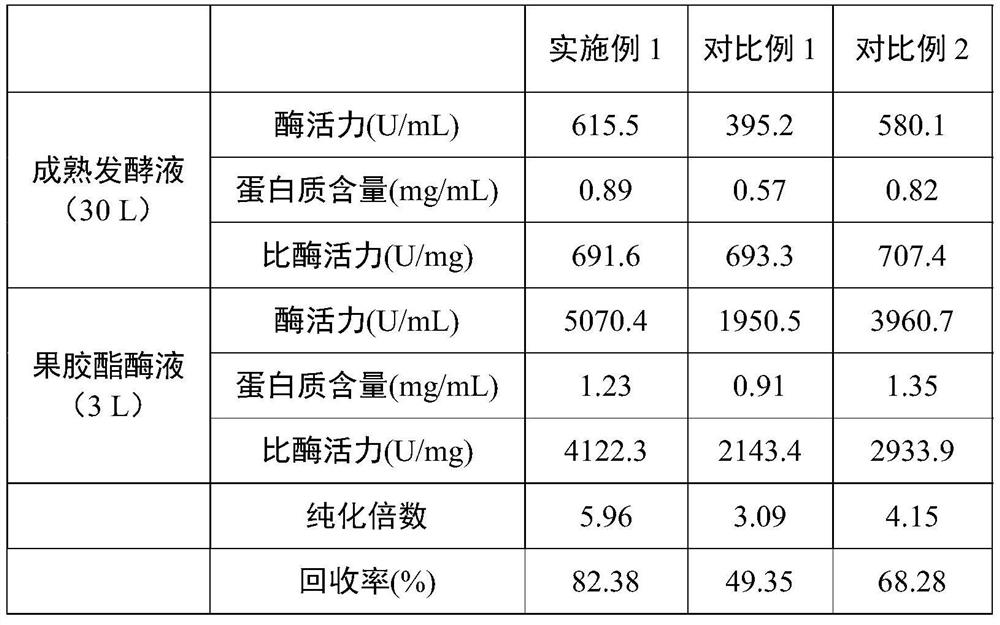

A pectin esterase and protease inhibitor technology, applied in the field of pectin esterase and its preparation, can solve the problems of prolonging the production cycle and increasing production costs, and achieve low cost, short fermentation cycle, and great theoretical and practical significance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation method of embodiment 1 pectin esterase

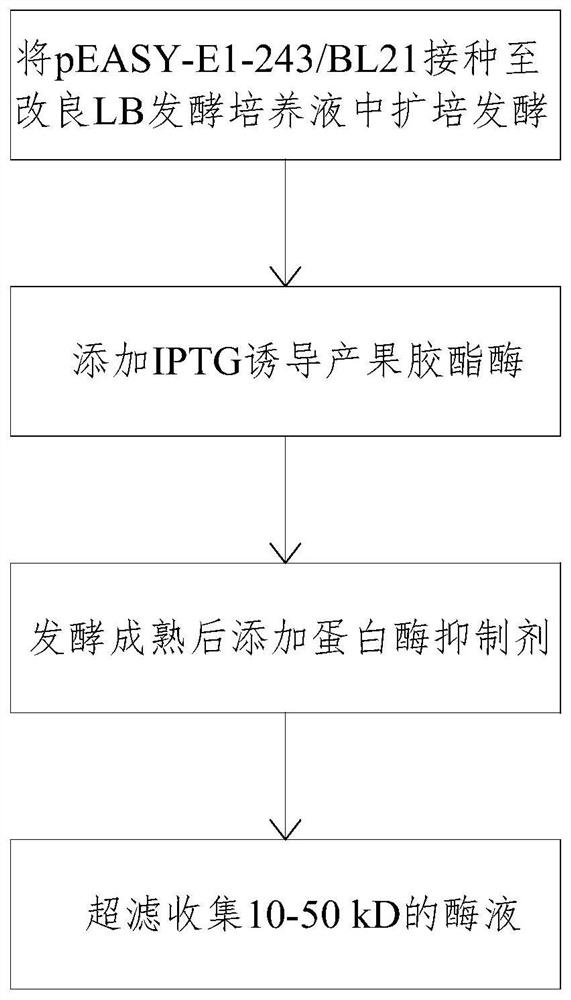

[0031] Such as figure 1 As shown, 1 mL of the genetically engineered bacteria pEASY-E1-243 / BL21 was inoculated into 200 mL of the improved LB culture medium (containing Amp 120 μg / mL), mixed thoroughly, 200 r / min, 37 ° C for 10-12 hours, that is, the seed solution.

[0032] The mass ratio formula of the above-mentioned improved LB culture solution is: glucose 0.5% + tryptone 1% + yeast extract 0.5% + NaCl 1%, and use NH 3 ·H 2 O to adjust the pH value to 7.5.

[0033] 600mL seed solution was directly inoculated into a 50L fermenter (Bio, Germany) filled with 30L modified LB culture solution (containing Amp120μg / mL), and ammonia water (NH 3 ·H 2 O), the pH is maintained to 7.0, the ventilation rate is 0.8m 3 / h, 37℃, 200r / min culture 3-4h, make OD 600 When it reaches about 0.5, add IPTG to a final concentration of 1.2mmol / L, change to 28°C for induction and culture for 12-18h, and then obtain a mature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com