A dental mold plaster treatment and processing device

A gypsum, dental mold technology, applied in grain processing, mixers with rotary stirring devices, transportation and packaging, etc., can solve the problems of low powder precision, inseparable braces, powder mixed into the air, etc., and achieve high powder precision. , the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

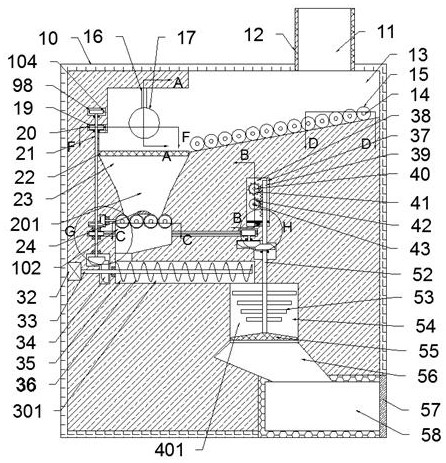

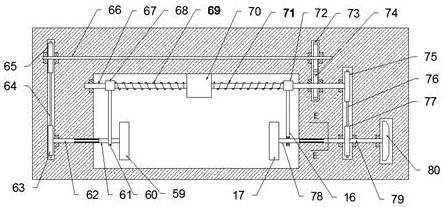

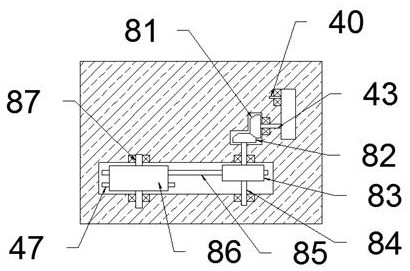

[0027] Such as Figure 1-9As shown, a dental mold gypsum treatment and processing device includes a housing 10, the upper end of the housing 10 is fixed with a discharge shell 12, the discharge shell 12 is provided with a discharge cavity 11, and the shell The body 10 is provided with a grinding chamber 13 located at the lower end of the discharge chamber 11, the grinding chamber 13 is provided with a rotatable tenth rotating shaft 67, and the inner wall of the upper end of the grinding chamber 13 is fixed with a fixed block 70, so The tenth rotating shaft 67 runs through the fixed block 70, and the front end of the fixed block 70 is fixedly provided with a positive thread 71, and the threaded connection on the positive thread 71 can move forward and backward, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com