Pipe supporting opening corrector

A straightener and pipeline technology, applied in the field of pipeline correction tooling, can solve problems such as pipeline deformation and large jack force, and achieve the effects of reducing over-correction and facilitating storage and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

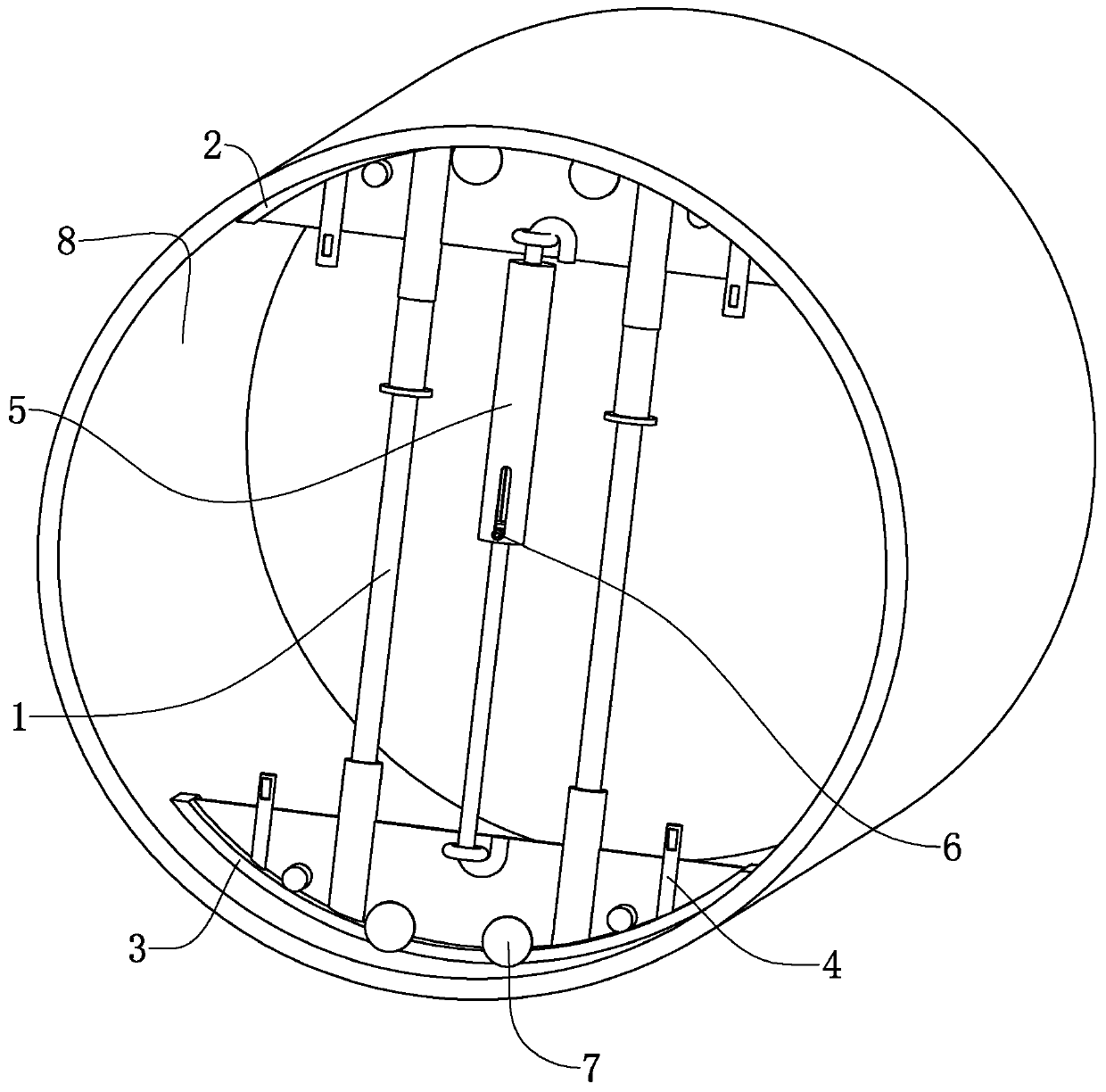

[0042] refer to figure 1, for the present invention discloses a pipe brace corrector, including an upper arc-shaped plate 2 and a lower arc-shaped plate 3 placed in the inner cavity of a curved straightening tube 8, and the radians of the upper arc-shaped plate 2 and the lower arc-shaped plate 3 Similarly, the upper curved plate 2 and the lower curved plate 3 are detachably connected with a length-adjustable top handle 1, and the two ends of the top handle 1 are respectively detachably connected with the upper curved plate 2 and the lower curved plate 3 .

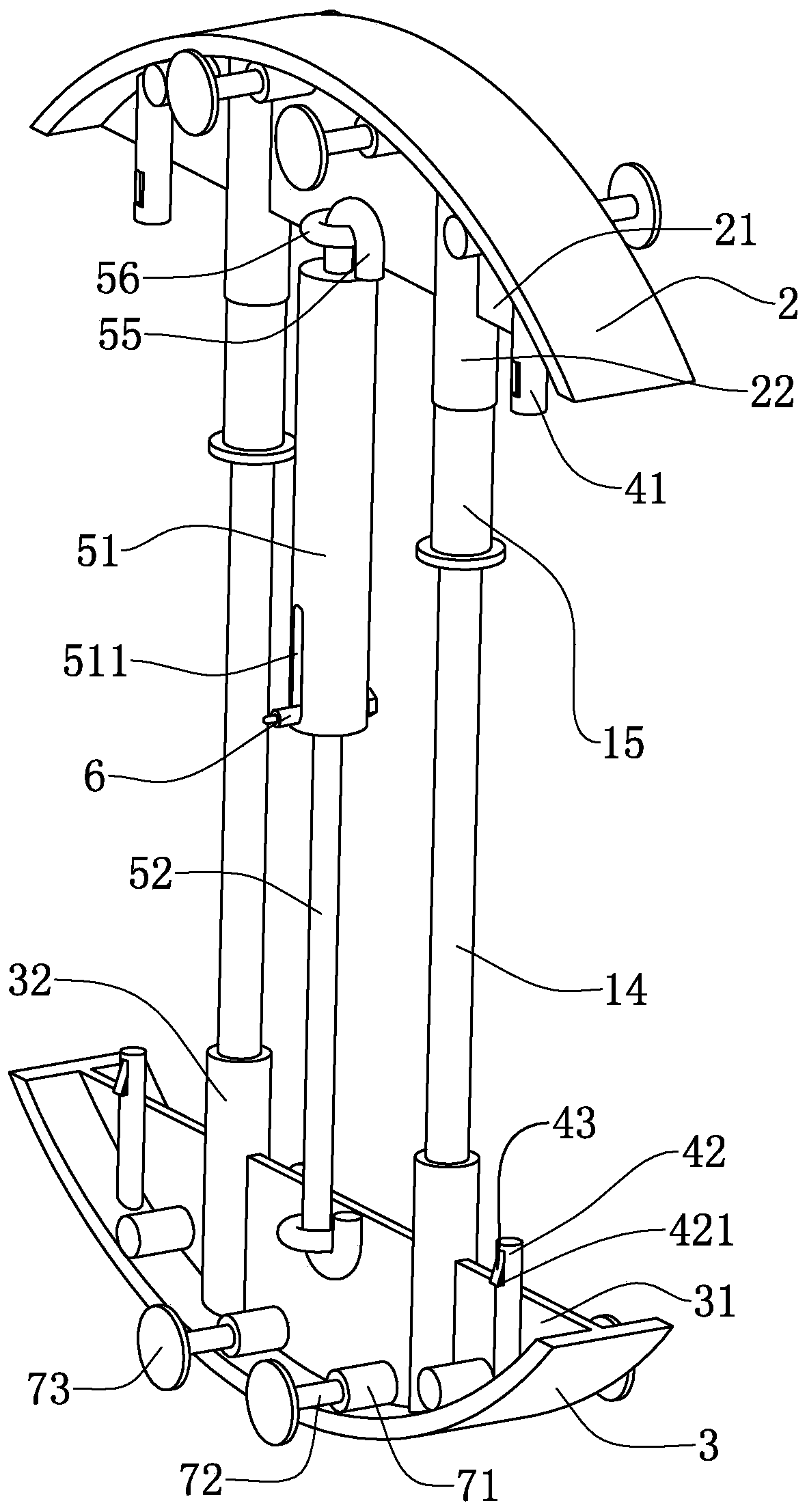

[0043] refer to figure 2 The inner side of the upper arc-shaped plate 2 is welded with an upper reinforcing plate 21, the thickness direction of the upper reinforcing plate 21 is parallel to the axial direction of the upper arc-shaped plate 2, and one side of the upper reinforcing plate 21 is matched with the inner surface of the upper arc-shaped plate 2. The arc surface, the other side of the upper reinforcing plate 21 ...

Embodiment 2

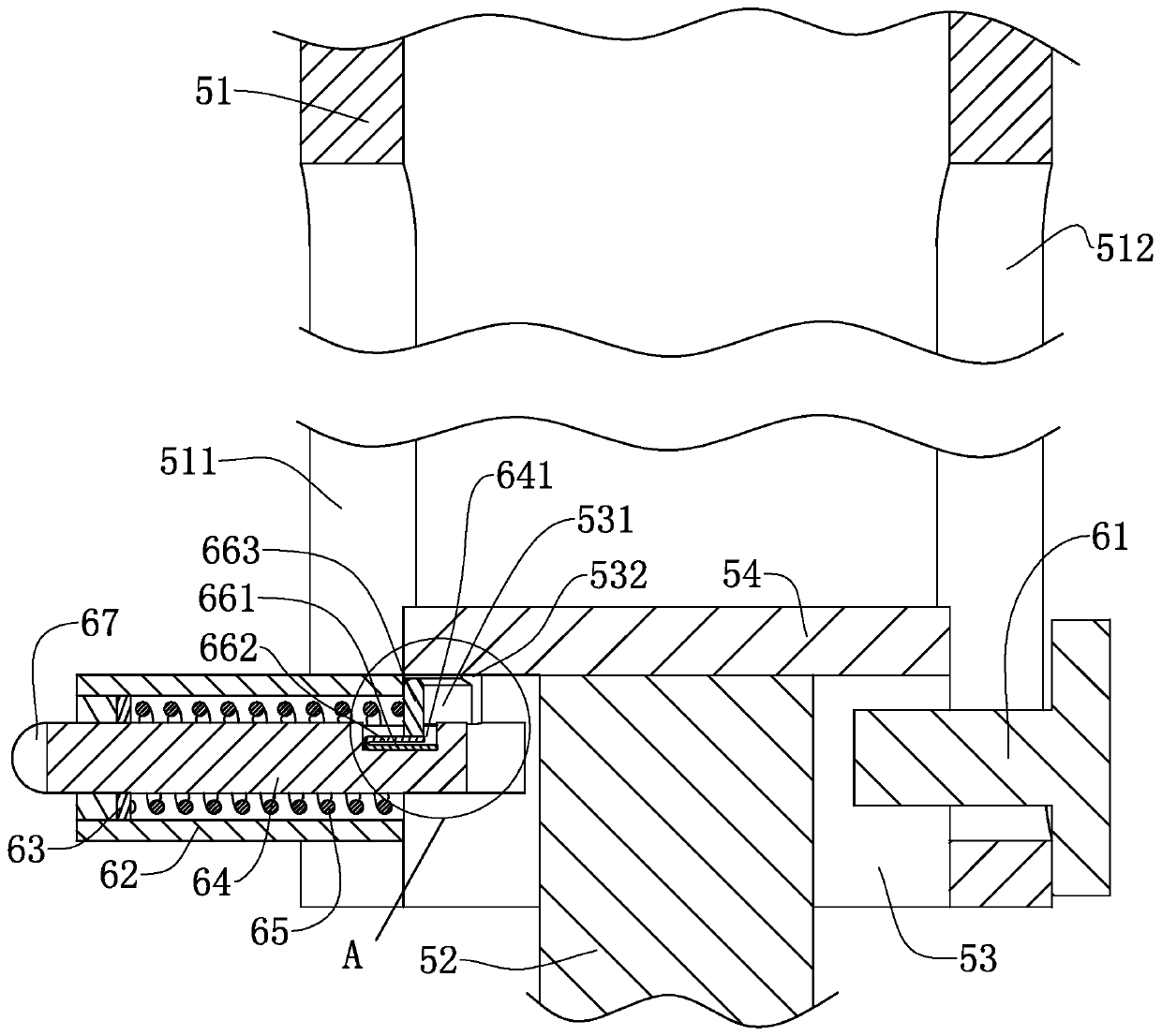

[0060] refer to figure 1 , a pipe brace straightening device, the difference from Embodiment 1 is that the jacking 1 includes an outer tube 11 and an inner rod 12 connected to one end of the outer tube 11, and the outer tube 11 is provided with a drive to drive the inner rod 12 along the The stretching mechanism 13 that moves in the axial direction of the outer tube 11 is provided with an external thread on the outside of the outer tube 11. The stretching mechanism 13 includes a drive screw sleeve fixed on the inner rod 12. The drive screw sleeve is sleeved on the inner rod 12 and connected to the inner The fixing ring that rod 12 is fixed has a screw sleeve integrally formed on the fixing ring, the inner surface of the screw sleeve is provided with an internal thread that cooperates with the outer tube 11, and the outer side of the screw sleeve is integrally formed with a hexagonal ring, and the transmission screw sleeve is threadedly connected with the outer tube 11. One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com