Sealing cover dismantling fixture and nuclear industrial waste barrel treatment device

A cover clamp and clamp technology, which is applied in the field of nuclear waste disposal equipment, can solve the problems of difficult maintenance of fully automatic cover unsealing equipment, lowering the efficiency of processing lines, and damage to operators, so as to reduce physical injuries of workers and production costs, and reduce The effect of adjusting the process multiple times and improving the processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

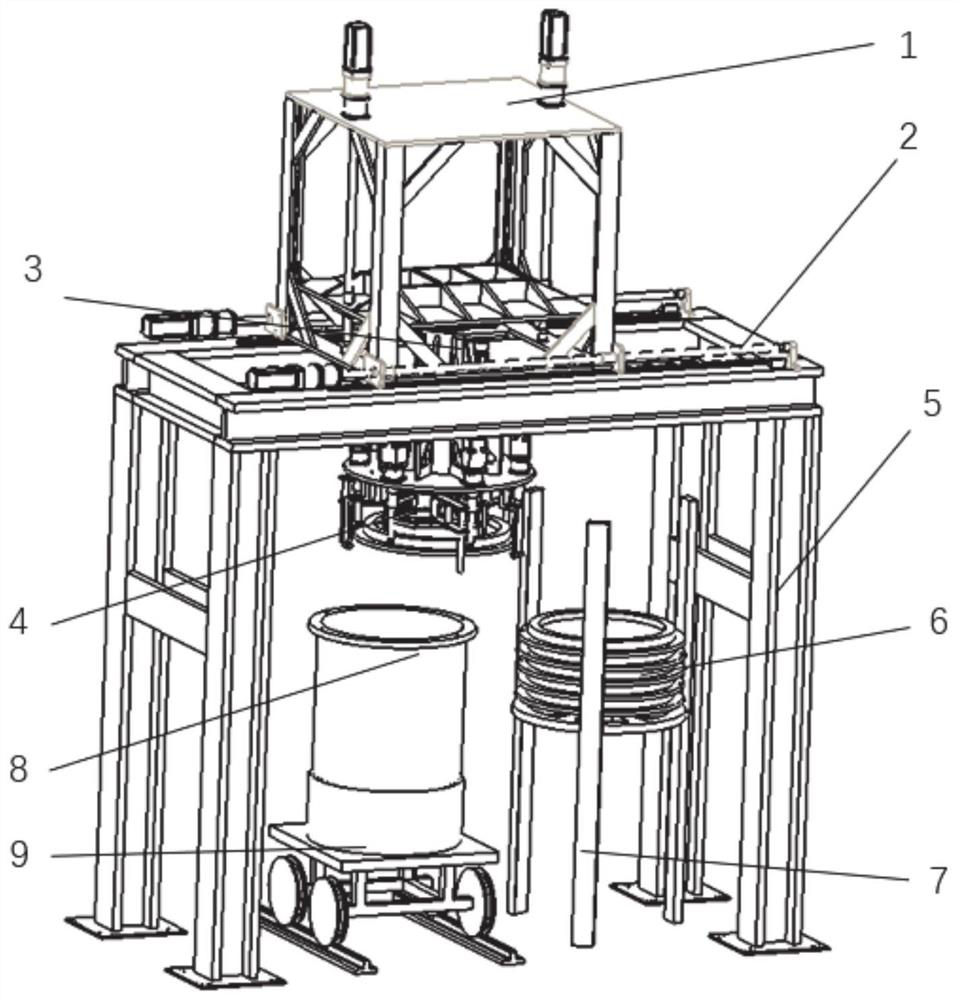

[0044] In a typical implementation of the present disclosure, such as Figure 1-Figure 16 As shown, a cap removal jig is proposed.

[0045] Such as Figure 5 As shown, it mainly includes an installation disc 42, a positioning claw 43, a dismounting mechanism and a clamp 46. According to the principle of three-point circle fixing, at least three positioning claws, at least three dismounting mechanisms and at least three clamps are configured;

[0046] All positioning claws are arranged symmetrically around the center of the disk axis and are respectively rotatably matched with the disk. The positioning claws rotate relative to the disk to synchronously change the distance between the positioning claws and the disk axis, thereby changing the diameter of the circle defined by the positioning claws. The positioning claws can Contact and press the waste barrel, push the waste barrel to the coaxial position with the disc gradually, and gradually position the waste barrel to the posit...

Embodiment 2

[0073] In another typical implementation of the present disclosure, such as Figure 1-Figure 16 As shown, a nuclear industry waste barrel disposal device is proposed.

[0074] It mainly includes a three-axis mechanical arm, a conveying mechanism, a storage rack and the capping fixture described in Embodiment 1. The conveying mechanism includes a slide rail and a transport trolley arranged on the slide rail. The three-axis mechanical arm is erected on the slide rail through a supporting frame Above the rail, the end of the three-axis mechanical arm rotates to cooperate with the capping fixture, and the storage rack is arranged below the support frame and on one side of the slide rail;

[0075] A position drive mechanism is installed at the end of the three-axis mechanical arm, and the position drive mechanism cooperates with the cap removal jig through a corresponding transmission mechanism to drive the cap removal jig to rotate as a whole.

[0076] Specifically, for the three...

Embodiment 3

[0095] In yet another typical embodiment of the present disclosure, a working method of the nuclear industry waste barrel disposal device in Embodiment 2 is given.

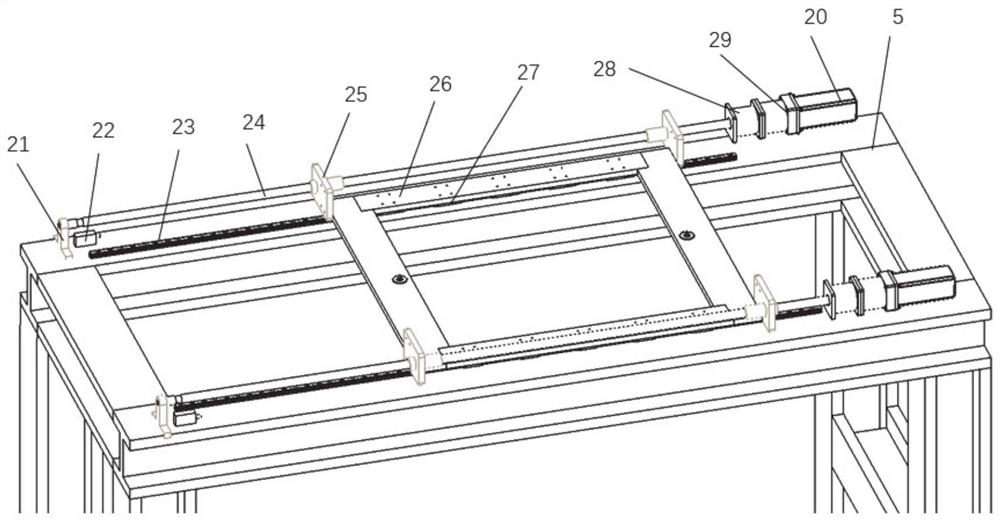

[0096] Such as figure 1 As shown, it is mainly composed of lifting mechanism 1, translation mechanism 2, rotation mechanism 3 and grasping mechanism 4. The above four mechanisms are installed on the support frame 5, and the removed metal bucket lid 6 is placed on one side On the bung storage frame 7 of the bung, the ladle body 8 is carried in and out by the transport dolly 9.

[0097] Its complete workflow is:

[0098] (1) Cap removal process

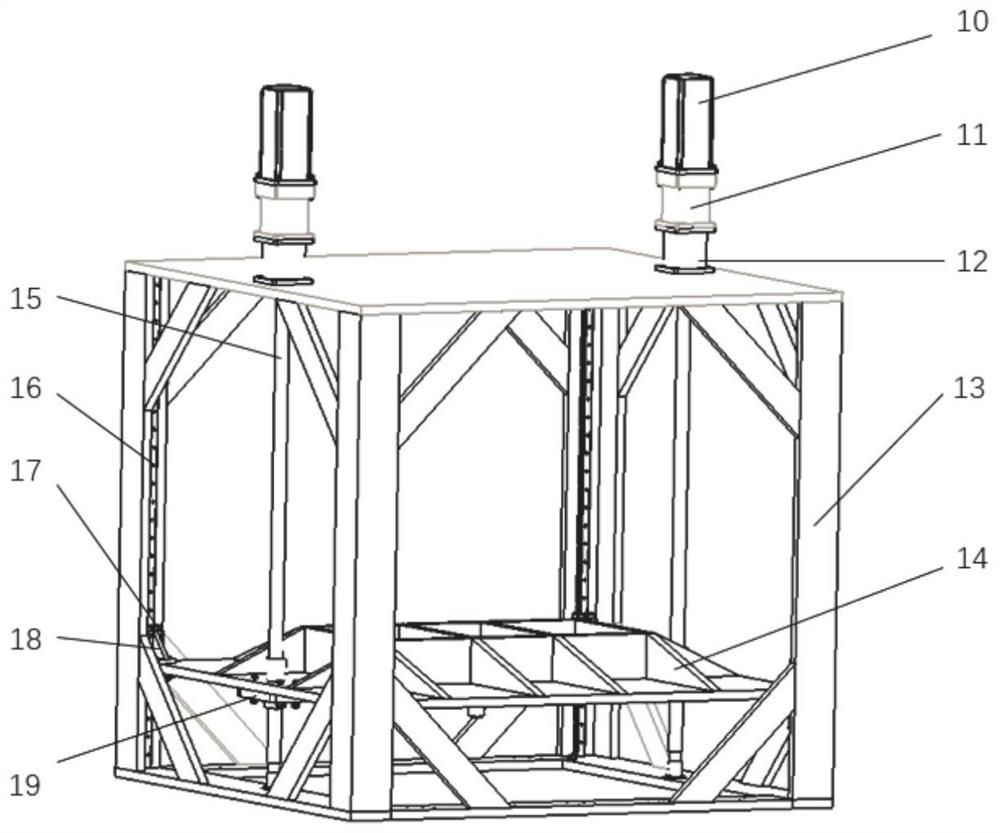

[0099] Such as figure 1 and figure 2 As shown, the transport trolley 9 transports the metal barrel with the cover to the designated position and stops, and the lifting mechanism 1 waiting above starts to move. Driven by the AC servo motor 10, the lifting mechanism 11 and the shaft coupling 12 lift The screw 15 rotates to drive the bearing plate 14 to descend. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com