Assembly device for super high-rise building diamond columns and assembly method of assembly device

An assembly device and super high-rise technology, applied in the processing of building materials, construction, auxiliary devices, etc., can solve the problems of the performance change of the diamond column, the difficulty is large, and the assembly accuracy of the diamond column is poor, so as to reduce multiple adjustments and production. Cost and effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings.

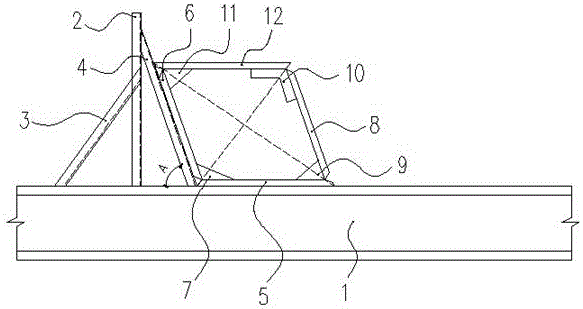

[0023] Such as figure 1 As shown, a super high-rise building rhombic column assembly device includes a horizontal assembly platform 1 and at least two assembly positioning structures; the assembly positioning structure is detachably fixed on the top surface of the assembly platform 1, and the assembly positioning structures are all Parallel to each other and on the same straight line; the assembly positioning structure includes a base (not shown in the figure), a support column 2, a fixed column 3 and a positioning column 4. The support column 2 is vertically fixed on the top surface of the base, and the positioning column 4 One end is fixed on the top surface of the base, and the other end of the positioning column 4 is welded to the middle and upper part of the support column 2. An acute angle A for assembling the rhombic column is formed between the positioning column 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com