A multi-pin device forming device

A molding device and multi-pin technology, applied in the field of multi-pin device molding devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be described in detail below with reference to the accompanying drawings and examples.

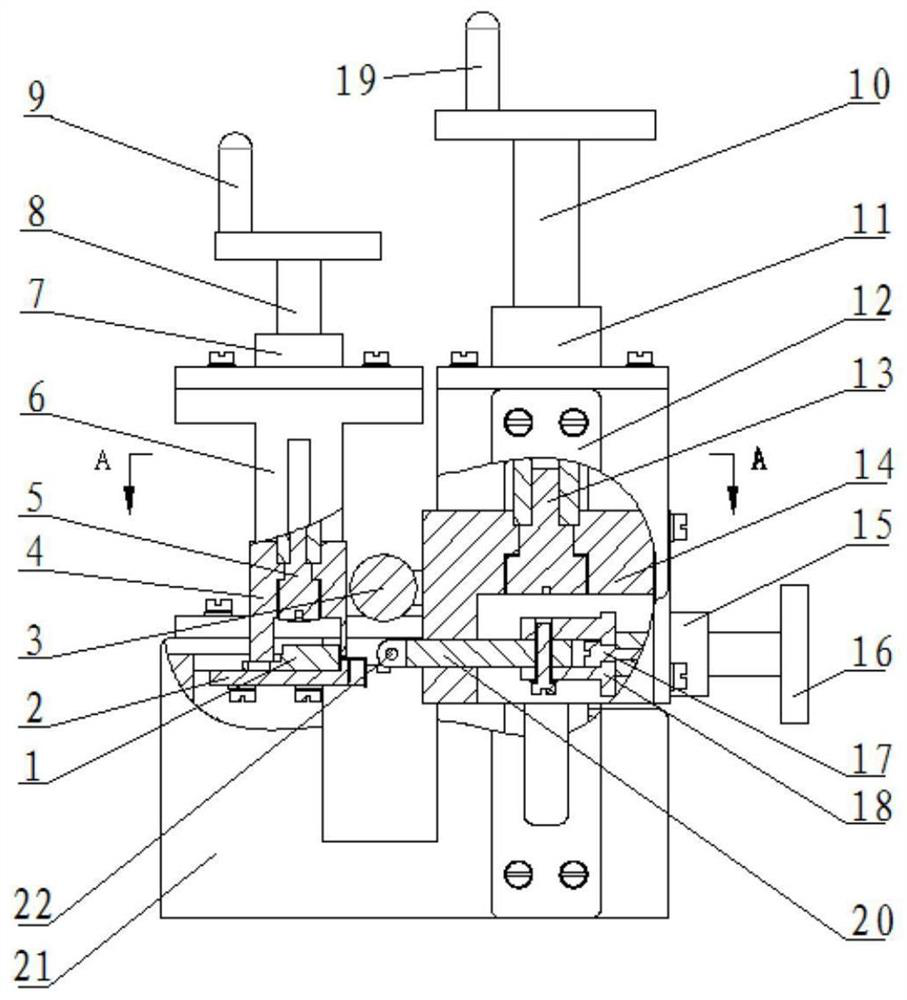

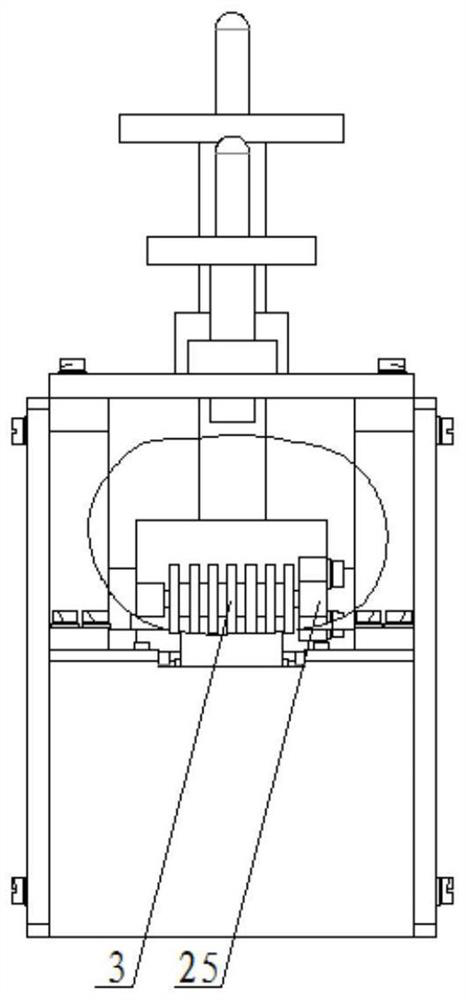

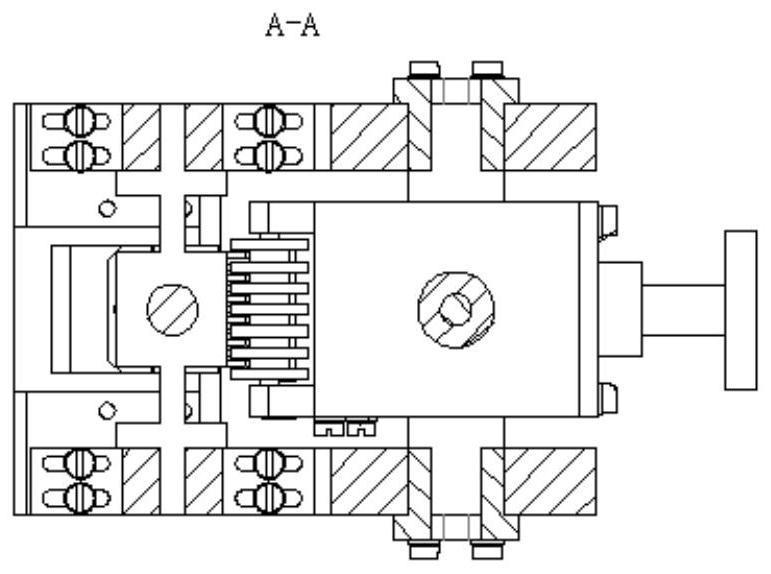

[0068] This embodiment provides a multi-pin device molding device, see the attached Figure 1-5 , including: device fixing components, device pin preliminary flattening components and device pin forming rolling components;

[0069] The device fixing assembly includes: a bracket 21, a pin forming template 2, a press-fit positioning member 4, a positioning screw shaft A5, a support plate 6, a left cover plate 7, a left screw shaft 8 and a first handle 9;

[0070] The device pin forming rolling assembly includes: pin rolling shaft 3, right screw shaft 10, right cover plate 11, guide plate 12, positioning screw shaft B13, forming frame 14, second handle 19 and rolling shaft stopper 25 ;

[0071] The device pin preliminary flattening assembly includes: side cover plate 15, horizontal screw shaft 16, positioning screw shaft C17, connecting frame 18, pin flatte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com