Production process of vehicle clothing film box

A production process and film box technology, which is applied in box making operations, paper/cardboard containers, container manufacturing machinery, etc., and can solve problems such as inability to print paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the application will be described in detail below with reference to the accompanying drawings. The description in this section is only exemplary and explanatory, and should not have any limitation on the scope of protection of the application. .

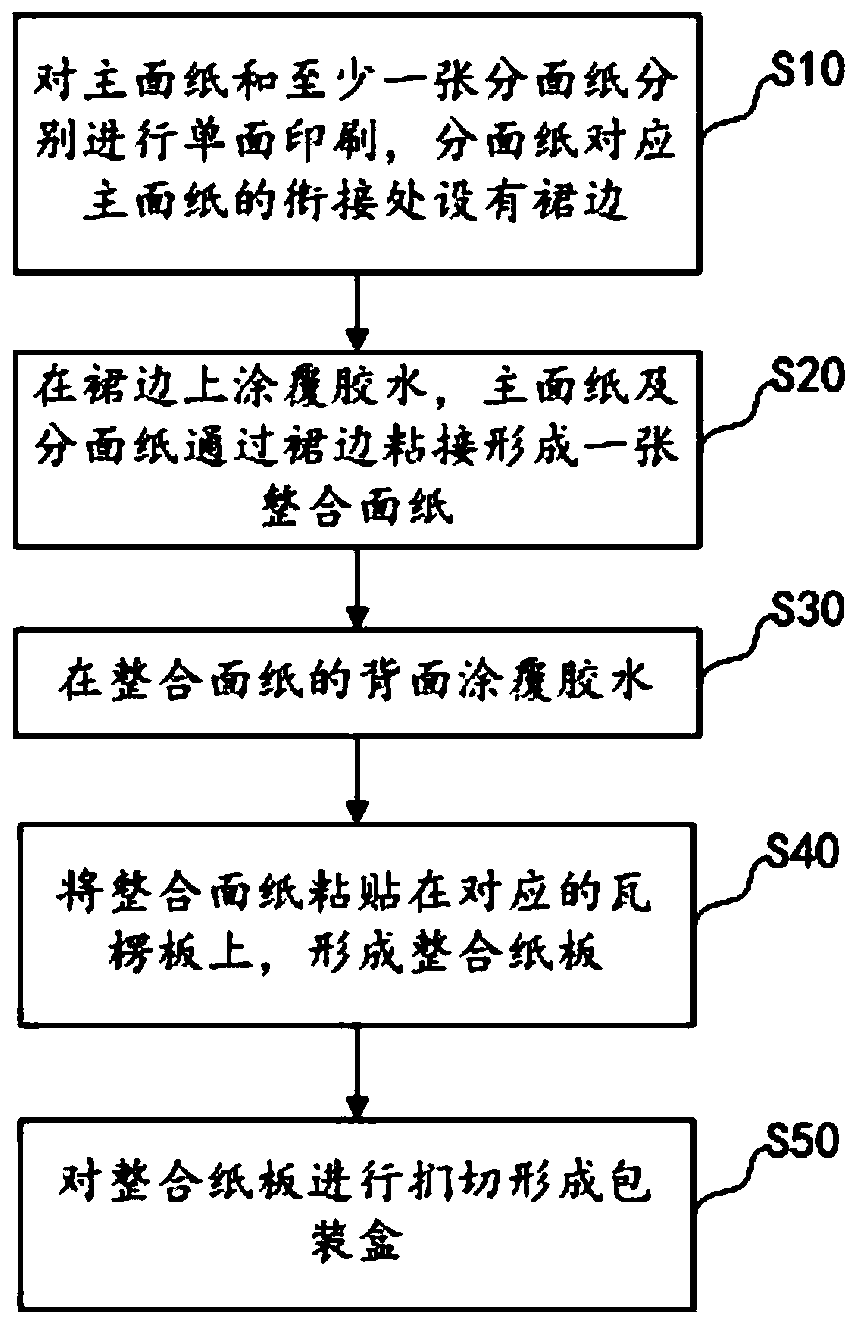

[0019] Such as figure 1 Shown as a flowchart of the first embodiment of this application, it includes the following steps:

[0020] S10. Perform single-sided printing on the main face paper and at least one facet paper respectively, and the facet paper is provided with a skirt at the junction corresponding to the main face paper.

[0021] The main face paper and the faceted paper are respectively printed on one side according to the pre-designed pattern. The patterns between the main face paper and the faceted paper may be the same or different, and the patterns between the faceted papers may be the same or different.

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap