Construction method of stand column pile

A construction method and column pile technology, which is applied in excavation, sheet pile wall, foundation structure engineering, etc., can solve problems such as difficulty in ensuring the stability of the steel cage and steel pipe position, difficulty in ensuring the concentric arrangement of steel pipe and steel cage, etc., to improve construction efficiency , reduce the occupied time, and achieve the effect of accurate welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

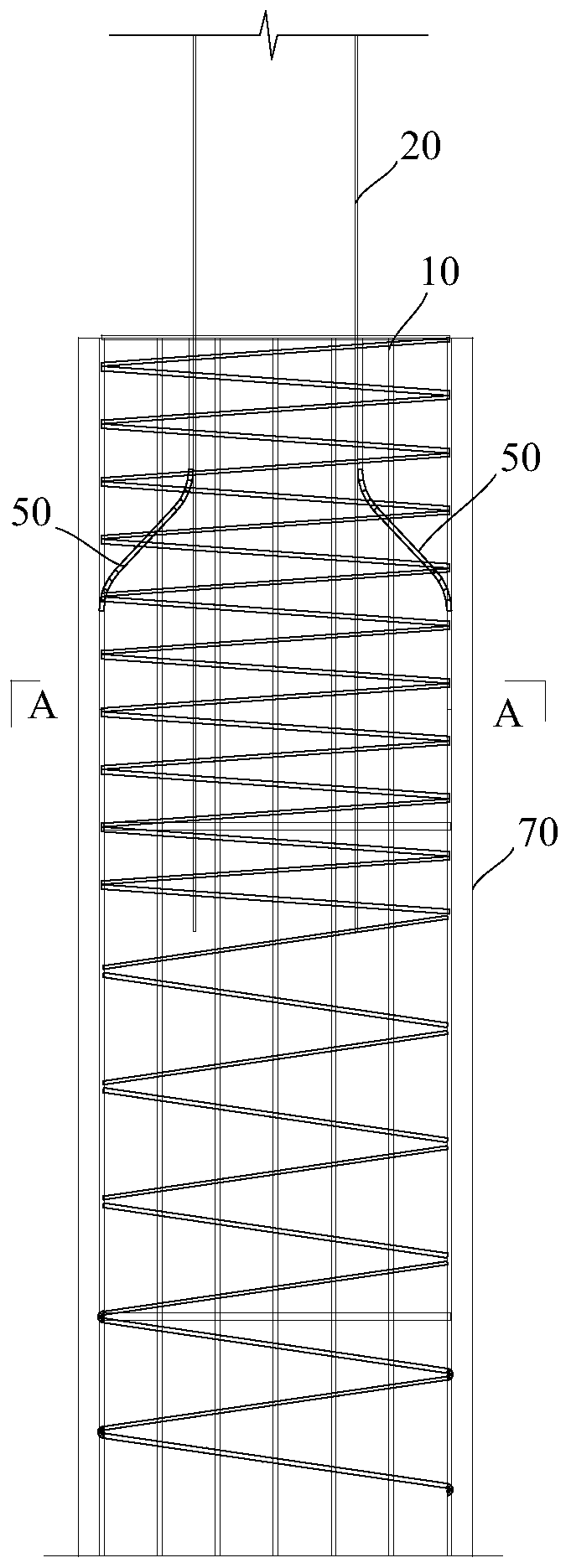

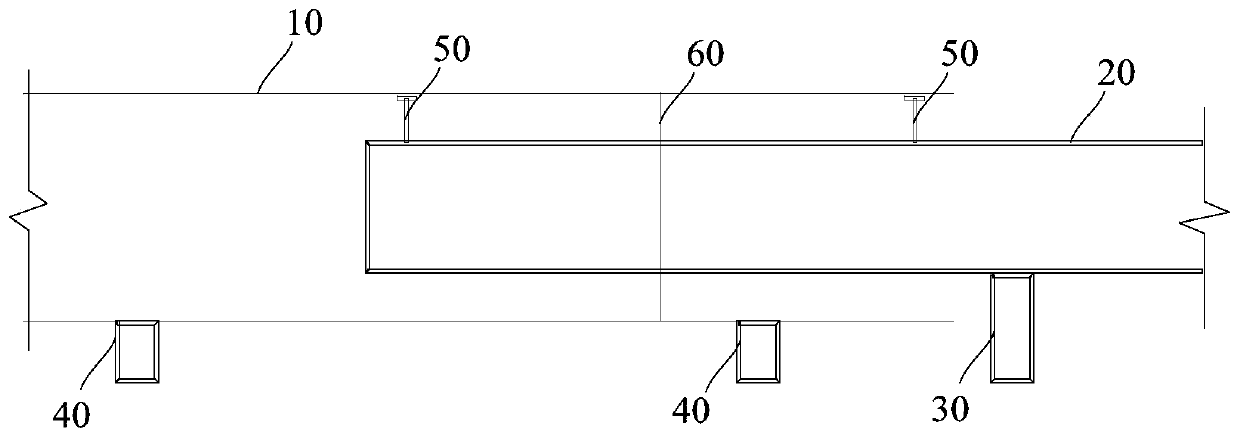

[0049] refer to figure 1 , shows the front view of the construction state of the construction method of the column pile of the present invention. Such as figure 1 Shown, the construction method of column pile of the present invention comprises the steps:

[0050] Excavation of pile holes;

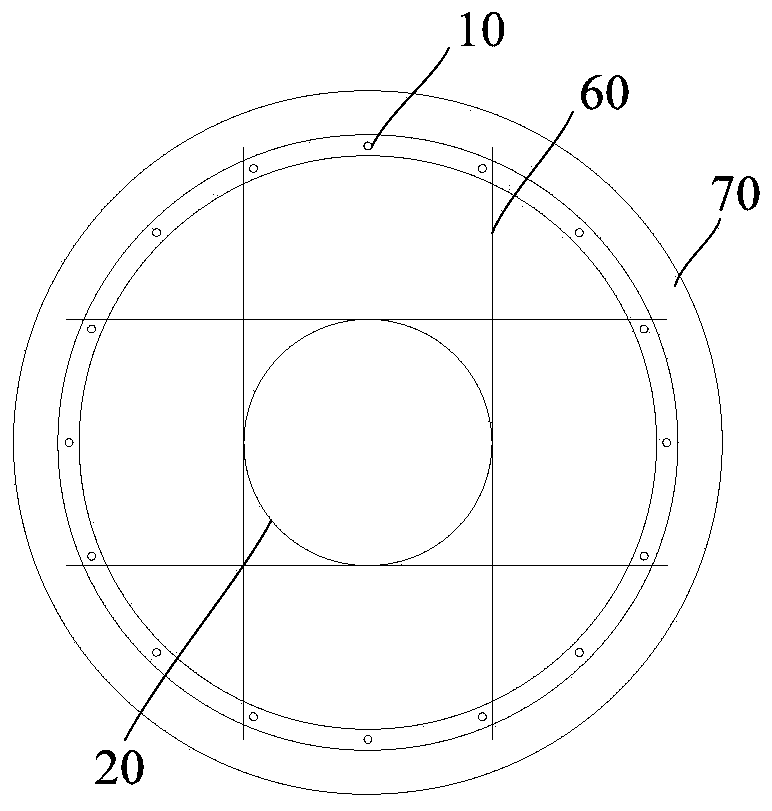

[0051] Provide reinforcement cage 10 and steel pipe 20, set steel pipe 20 and reinforcement cage 10 concentrically and fasten them into one;

[0052] hoisting the reinforcement cage 10 and the steel pipe 20 to the top of the pile hole as a whole, aligning the center of the reinforcement cage 10 and the steel pipe 20 with the center of the pile hole and inserting them in the pile hole; and

[0053] Concrete is poured into the pile holes to form the stud piles.

[0054] The reinforcement cage 10 includes: main bars, spiral hoops and stiffening hoops, with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com