Roller bearing retainer

A technology of roller bearings and cages, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems affecting balance, bearing life, and cage wear, and achieve reduced resistance, stable operation, and small impact loads Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be described and described in detail below in conjunction with the accompanying drawings.

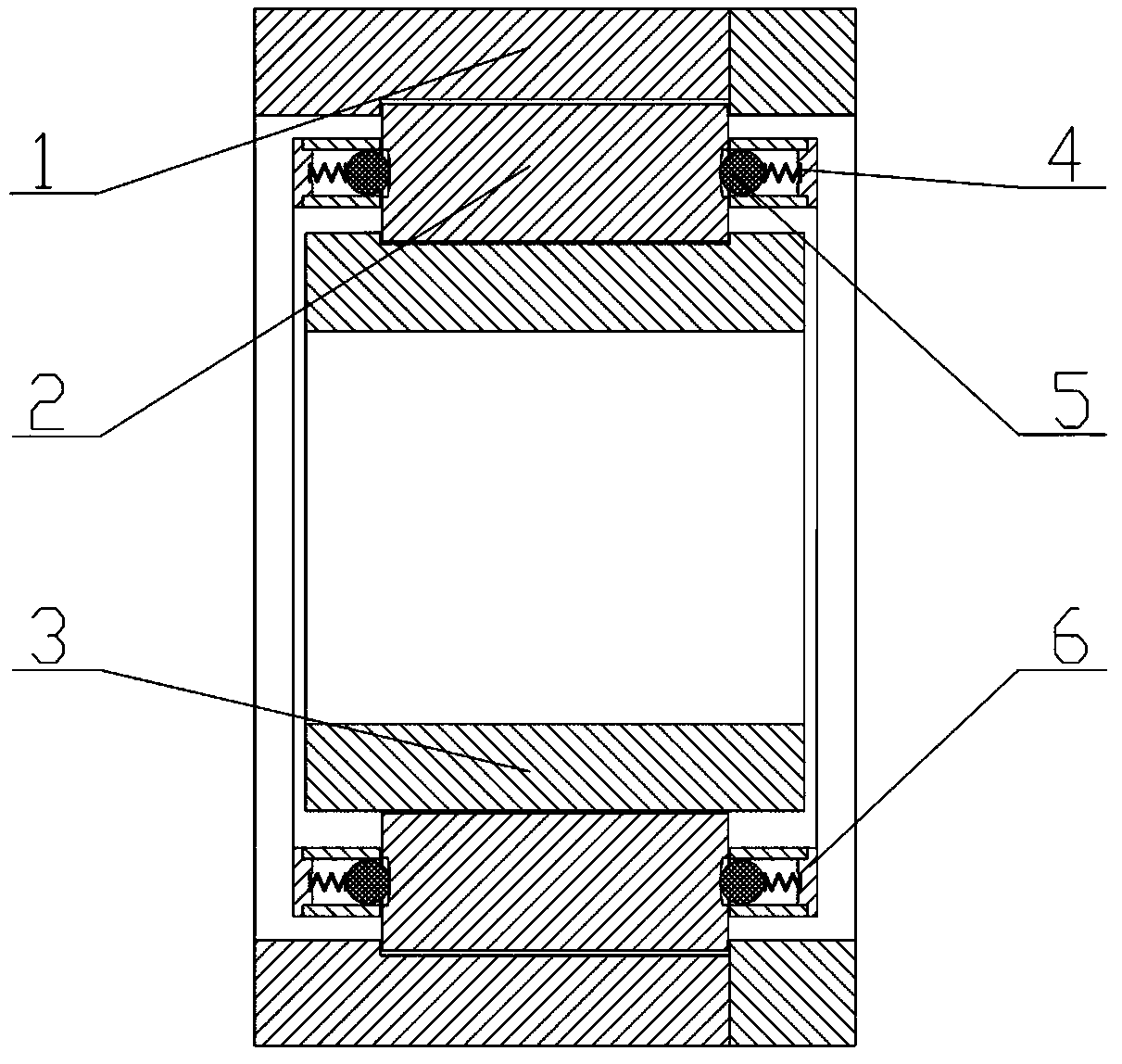

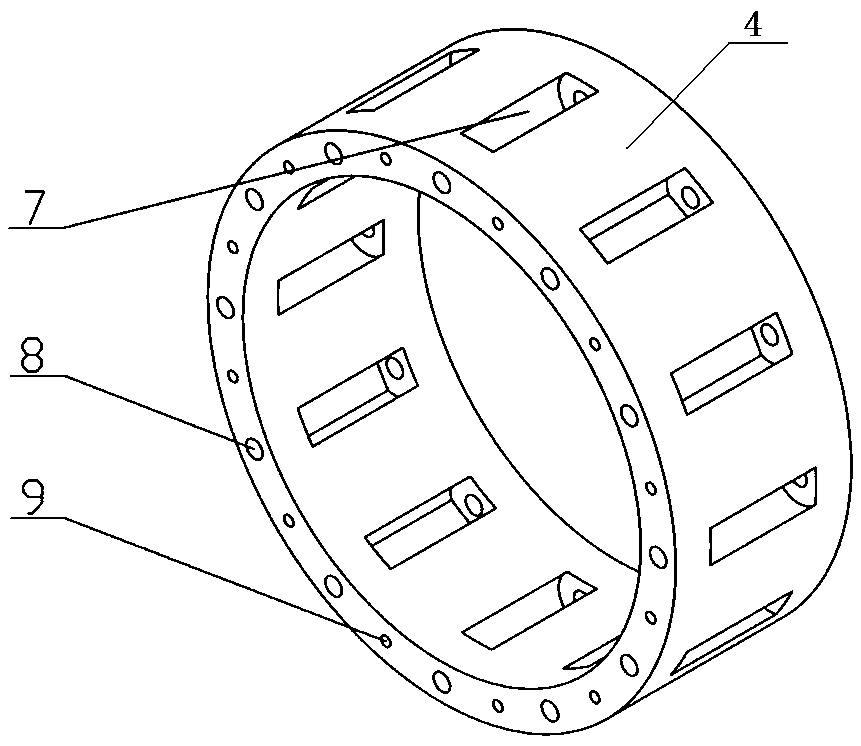

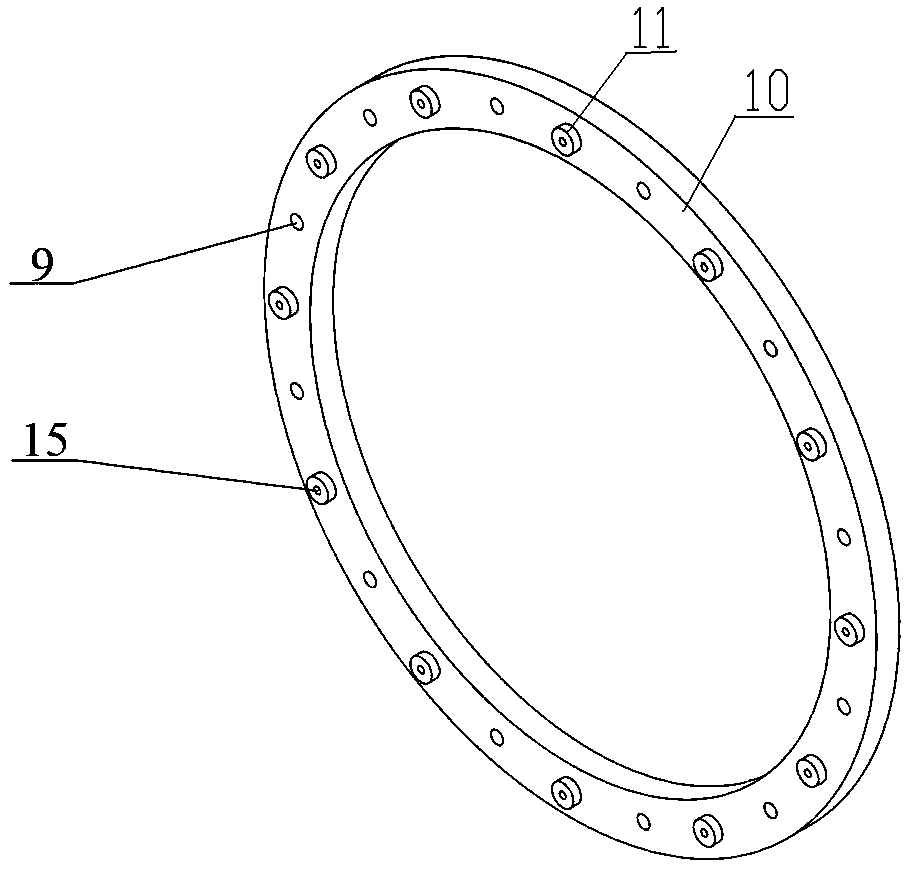

[0019] As shown in the figure, a roller bearing cage is characterized in that it includes a cage body 4 and an annular cage baffle 10 connected to both sides of the cage body 4 and matching the shape of the cage body 4 A through hole 8 communicating with the pocket hole 7 is provided on both sides of the end surface of the cage body 4 corresponding to each pocket hole 7, and a convex hole 8 that is matched with each through hole 8 is provided on the corresponding position of the retainer baffle plate 10. Out of the column 11, the cage main body 4 and the cage baffle 10 are connected through the protruding column 11 and the through hole 8, and the through holes 8 on both sides of the bearing roller 2 are respectively provided with supporting balls from the bearing roller 2 to the outside. 5 and spring 6, support bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com