Ultrasonic detection method for judging lubricating state of rolling bearing under actual working conditions

A technology for rolling bearings and actual working conditions, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, and analysis materials. The effect of machine damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

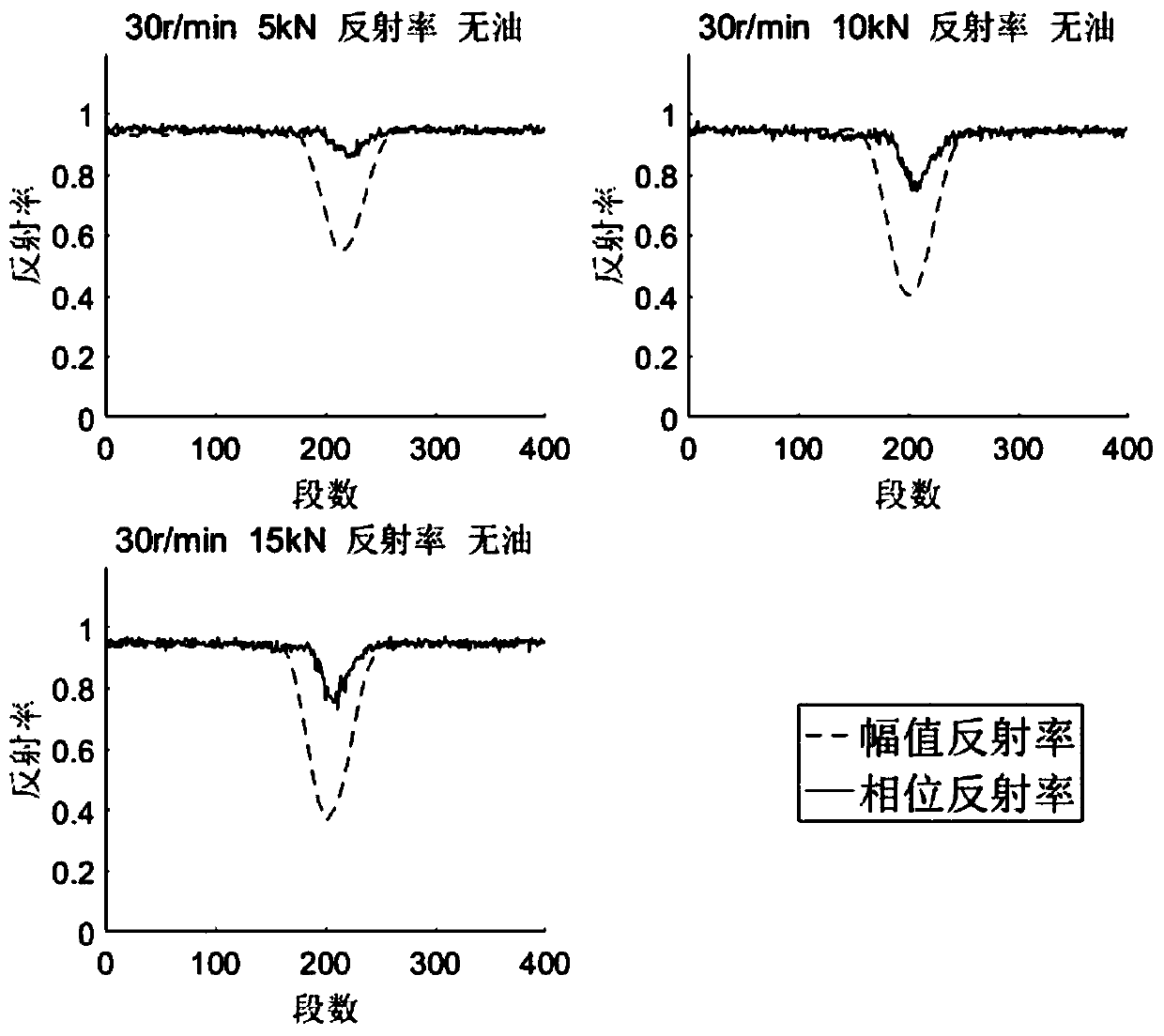

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below with reference to the accompanying drawings.

[0025] The present invention provides an ultrasonic detection method for judging the lubrication state of rolling bearings under actual working conditions, comprising the following steps:

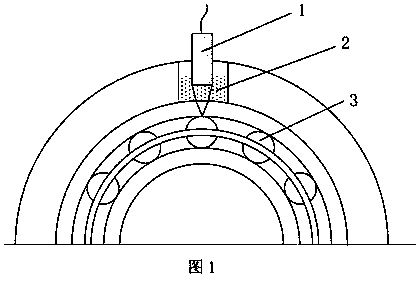

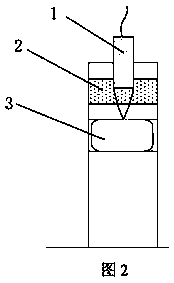

[0026] (1) Selection, installation and adjustment of ultrasonic sensors

[0027] According to the type of test bearing, the working environment of the test, and the speed range, the ultrasonic sensor required for the test is selected. The main parameters include the center frequency of the ultrasonic sensor, the focus diameter (the straight probe is the diameter of the chip), the focal length, temperature range etc. Install the ultrasonic sensor on the bearing seat, and adjust the ultrasonic sensor to a suitable position through the adjustment device (electric or manual multi-degree-of-freedom adjustment platform, etc.), while ensuring good contact between the outer surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com