Cloth defect detection method based on multi-modal fusion deep learning

A cloth detection and defect detection technology, which is applied in neural learning methods, character and pattern recognition, biological neural network models, etc., can solve problems such as cloth defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A cloth defect detection method based on multi-modal fusion deep learning proposed by the present invention is described in detail as follows in conjunction with the accompanying drawings and embodiments:

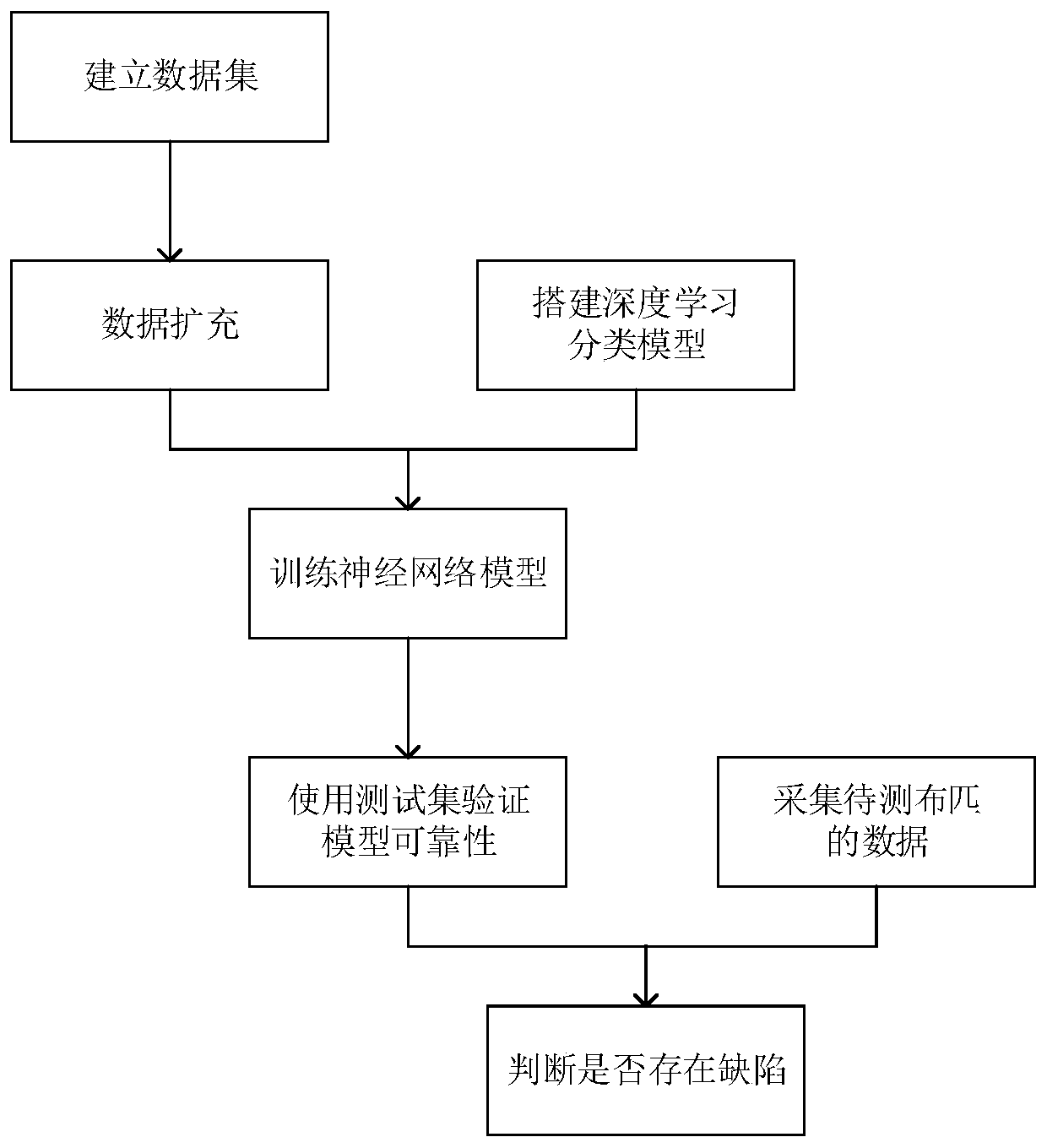

[0021] see figure 1 , is an overall flowchart of the embodiment of the present invention, including the following steps:

[0022] Step 1: Establish a cloth detection data set for different types of defects

[0023] Contact the tactile sensing sensor with the surface of cloth with different defects, and collect the cloth texture images of various defects. The defects of cloth are divided into normal, structural defects and color defects. The structural defects include scraping, thinning and neps , holes, roving, creases and running needles, and the color defects include dirt, color flowers, color yarn, dye flowers, black spots, missing prints and dark lines; use the camera at the same position where the tactile perception sensor collects the cloth texture The extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com