A safe and energy-saving anti-snow device for overhead cables

An overhead cable and energy-saving technology, which is applied in the field of snow-prevention devices for safety and energy-saving overhead cables, can solve problems such as difficulty in clearing and easy accumulation of snow on overhead cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

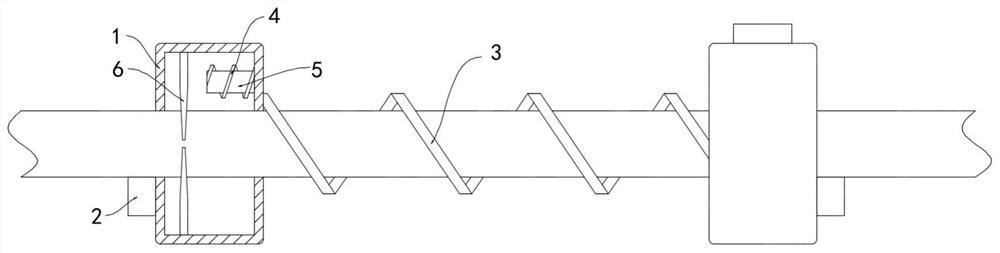

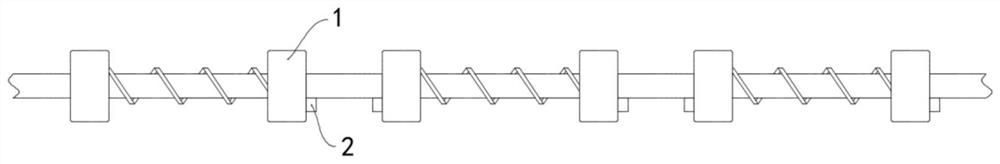

[0018] Such as Figure 1-2 As shown, a safe and energy-saving anti-snow device for overhead cables includes a plurality of snow removal parts sleeved outside the cables. The side walls of the body 1 away from each other are fixedly connected with permanent magnet blocks 2, and the multiple permanent magnet blocks 2 are all repelled by the same pole. The cable is provided with a spiral brush strip 3 formed by spirally curling long stainless steel shrapnel. The spiral brush strip 3 is attached on the surface of the cable, and the two ends of the spiral brush strip 3 are respectively fixedly connected with two annular shells 1, and the inner walls of the two annular shells 1 are fixedly connected with electromagnets 4, and the electromagnetic The iron 4 is made of silicon steel material. The two electromagnets 4 are wound with an induction coil 5. The winding directions of the two induction coils 5 are opposite. The non-contact discharge needles 6 and the two ends of the inducti...

Embodiment 2

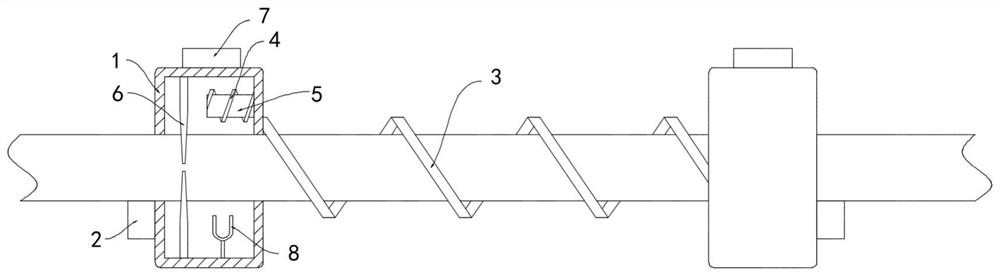

[0021] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 lies in that: a whistle 7 is fixedly installed on the side wall of the annular housing 1 , and a resonant rod 8 is fixedly installed on the inner wall of the annular housing 1 .

[0022] In this embodiment, the wind in the sky blows the whistle tube 7 to make a sound, and the vibration caused drives the resonant rod 8 to vibrate. Because the inner seal of the annular shell 1 forms a resonant cavity, the vibration of the resonant rod 8 can last for a long time , Then cause the cable to vibrate, shake off the snow, and play the role of assisting snow removal.

Embodiment 3

[0024] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that a horizontally arranged wing plate 9 is provided below the annular housing 1, and a horizontally arranged lifting plate 10 is slidably connected to the inner side wall of the annular housing 1. The plate 10 is fixedly connected to the wing plate 9 through the connecting rod, one of the discharge needles 6 is fixedly installed on the upper top surface of the annular housing 1, and the other discharge needle 6 is fixedly installed on the upper surface of the lifting plate 10, and the wing plate 9 is set Below the annular housing 1, the snow accumulation on the wing plate 9 can be reduced. At the same time, when the annular housing 1 moves, the wing plate 9 can be moved to shake off the snow on the wing plate 9 to ensure that the wing plate 9 can be used in snowy weather. normal work.

[0025] In this embodiment, when there is no wind and no snow, the distance between the two disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com