Viscous adsorption method of test probe cleaning method

A technology for testing probes and cleaning, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc. The effect of ensuring the test yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0053] The following is a specific implementation of a test probe cleaning device of the present invention.

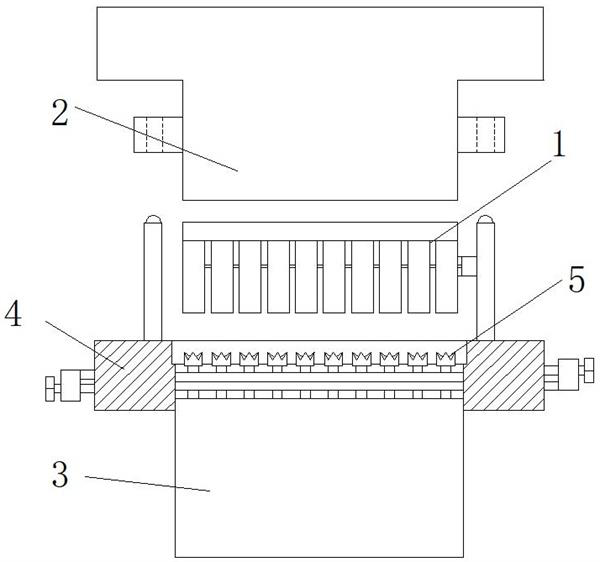

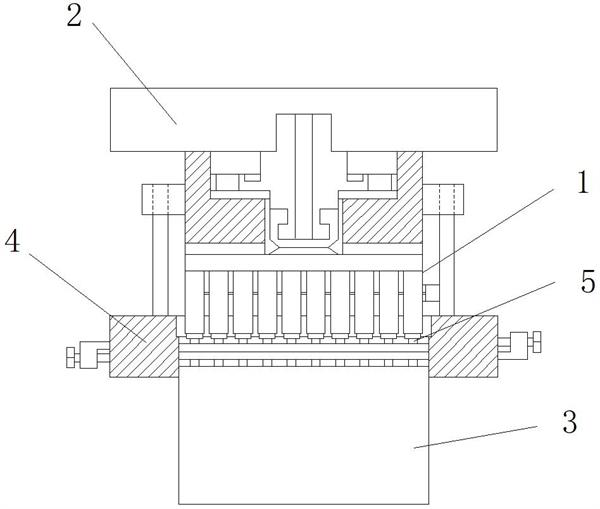

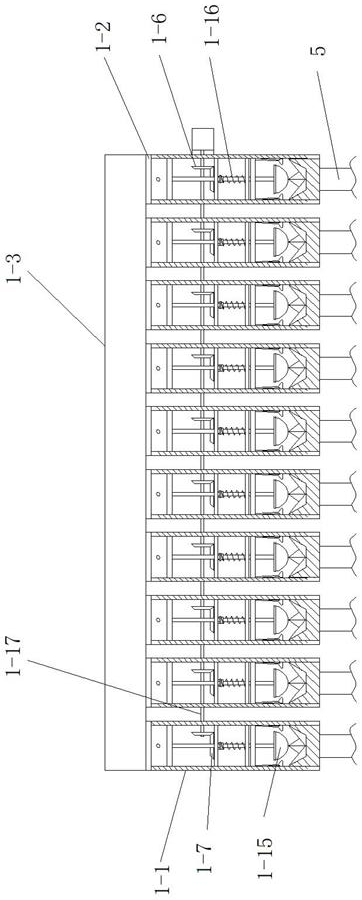

[0054] The test probe cleaning device under the present embodiment, such as Figure 1-9As shown, the test probe cleaning device includes a cleaning component 1, a clamping component 2, a test socket 3, a test base 4 and a test probe 5; the clamping component 2 is arranged above the cleaning component 1, and the cleaning component 1 is provided with a test socket 3 below, and the test socket 3 is installed on the test base 4. The clamping member 2 can control the cleaning member 1 above the test socket 3 through the movement of the transmission mechanical arm, and the cleaning member 1 can be moved to In the test socket 3, and fit against the probe of the test probe 5 in the test socket 3, to complete the work of scraping off the accumulated impurities on the test probe 5 first, and then absorbing and removing the impurities and dust from the test socket 3 , that is, t...

specific Embodiment approach 2

[0067] The following is a specific implementation of a test base of a test probe cleaning device of the present invention.

[0068] It should be noted that the test base of a test probe cleaning device in this embodiment can be implemented separately, that is, it can exist independently as a part of a test probe cleaning device, or it can be described in Embodiment 1. A test probe cleaning device is further defined.

[0069] The test base of the test probe cleaning device under the present embodiment, such as figure 1 , 2 , 7, 8, the test base of the probe cleaning device includes a base body 4-1, a first limiting clip 4-3, a second limiting clip 4-4, a first lead screw nut 4 -5. The second lead screw nut 4-6, the first adjusting bolt 4-7, and the second adjusting bolt 4-8; the side wall of the base body 4-1 is symmetrically opened with two groups of strip-shaped through holes, the first The limit clip 4-3 and the second limit clip 4-4 are movably arranged in two groups of ...

specific Embodiment approach 3

[0073] The following is a specific implementation of a clamping member of a test probe cleaning device of the present invention.

[0074] It should be noted that the clamping member of a test probe cleaning device in this embodiment can be implemented separately, that is, it can exist independently as a part of a test probe cleaning device, or it can be described in Embodiment 1. A test probe cleaning device is further defined.

[0075] The clamping member of the test probe cleaning device under the present embodiment, such as figure 1 , 2 , 9, the clamping member of the probe cleaning device includes a clamping body 2-1, an air pipeline 2-3, and a sealing plate 2-4; the lower part of the inner cavity of the clamping body 2-1 is provided with an adsorption port 2-2, there is an air pipeline 2-3 inside the clamping body 2-1, the suction end of the air pipeline 2-3 reaches the suction port 2-2, and the clamping body 2-1 can pass through the air pipeline The adsorption port 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com