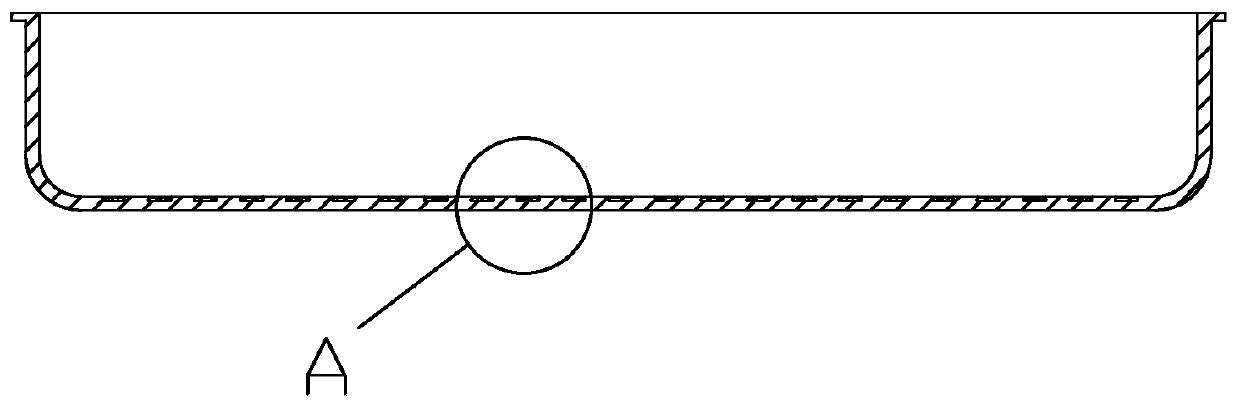

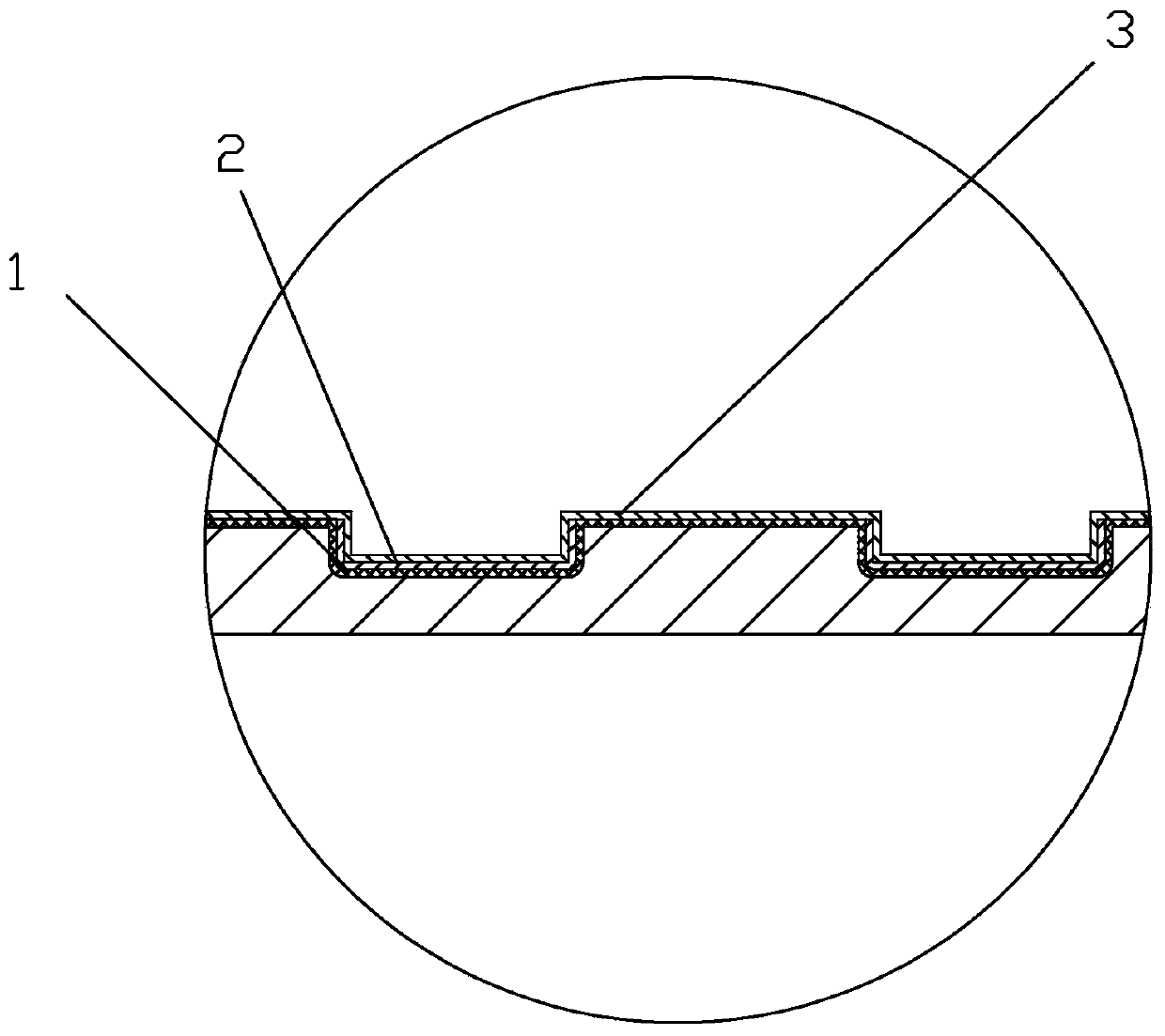

Non-stick coating spraying process for non-stick pan with concavo-convex patterns

A non-stick coating, embossed pattern technology, applied in coatings, abrasives, kitchen utensils, etc., can solve problems such as difficulty in meeting use requirements, no non-stick coating, coating damage, etc. Increase adhesion, increase non-stick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below through specific embodiments.

[0027] A non-stick paint spraying process with a concave-convex pattern non-stick pan, the process steps are as follows:

[0028] Step S1: Perform high-temperature degreasing treatment on the pot body blank that needs to be sprayed with non-stick coating; the high-temperature degreasing described in this step refers to sintering the residual grease of the pot body blank in a high-temperature furnace at a temperature of 150°C to 450°C; this step Mainly use high temperature to remove the dirt left by stretching the surface of the pot body blank;

[0029] Step S2: Carry out sandblasting treatment on the inner surface of the pot body blank, and the thickness of the sandblasting treatment is 0.3um to 4.5um; this step mainly performs high-pressure sandblasting treatment on the inner surface of the pot body blank, and the material used for the sandblasting treatment...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap