Device for high-speed detection of small hole of cartridge shell body

A pod and shell technology is applied in the field of electronic cigarette component detection devices to achieve the effects of reliable action, reasonable design and structure, and low false detection rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

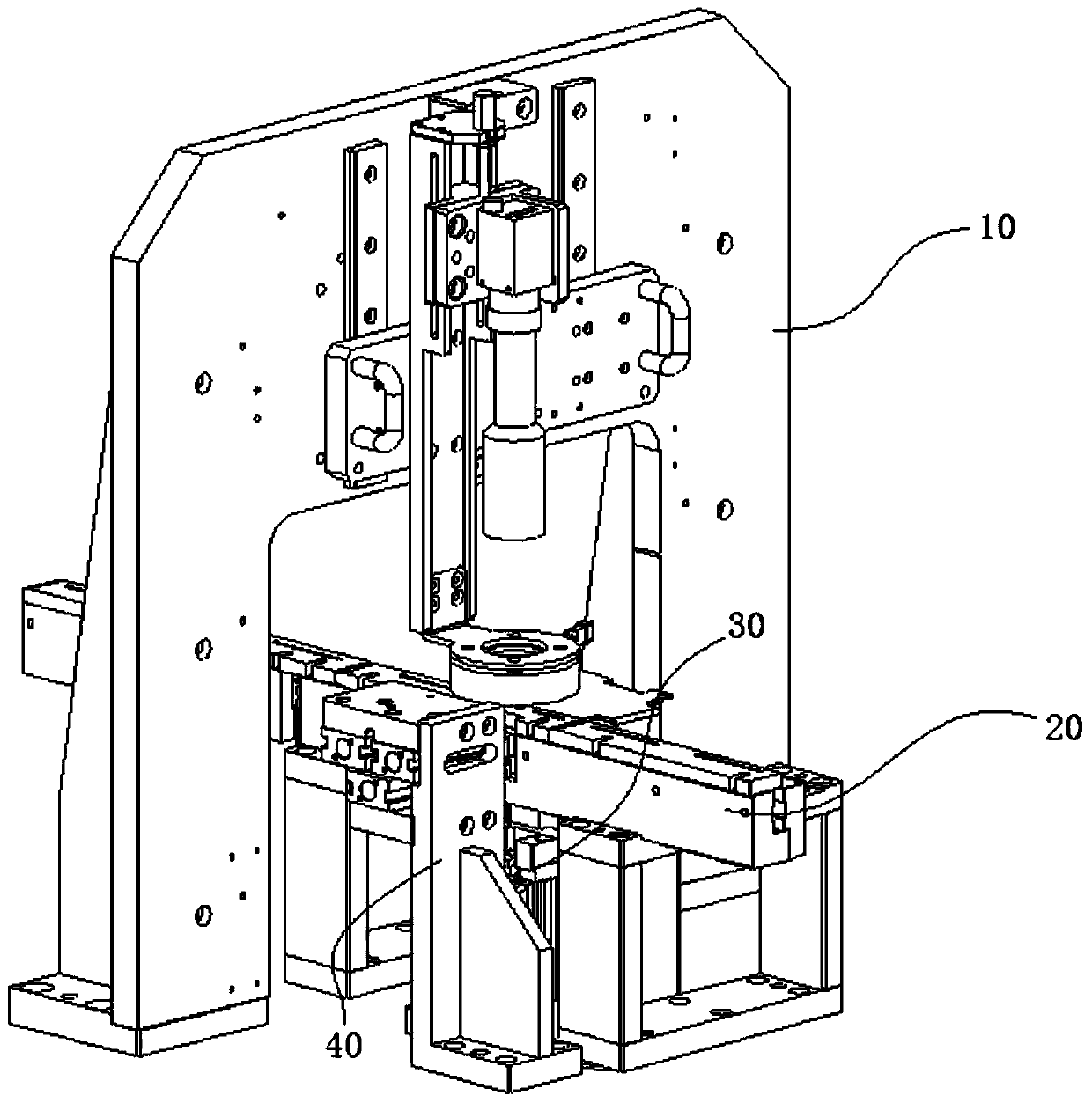

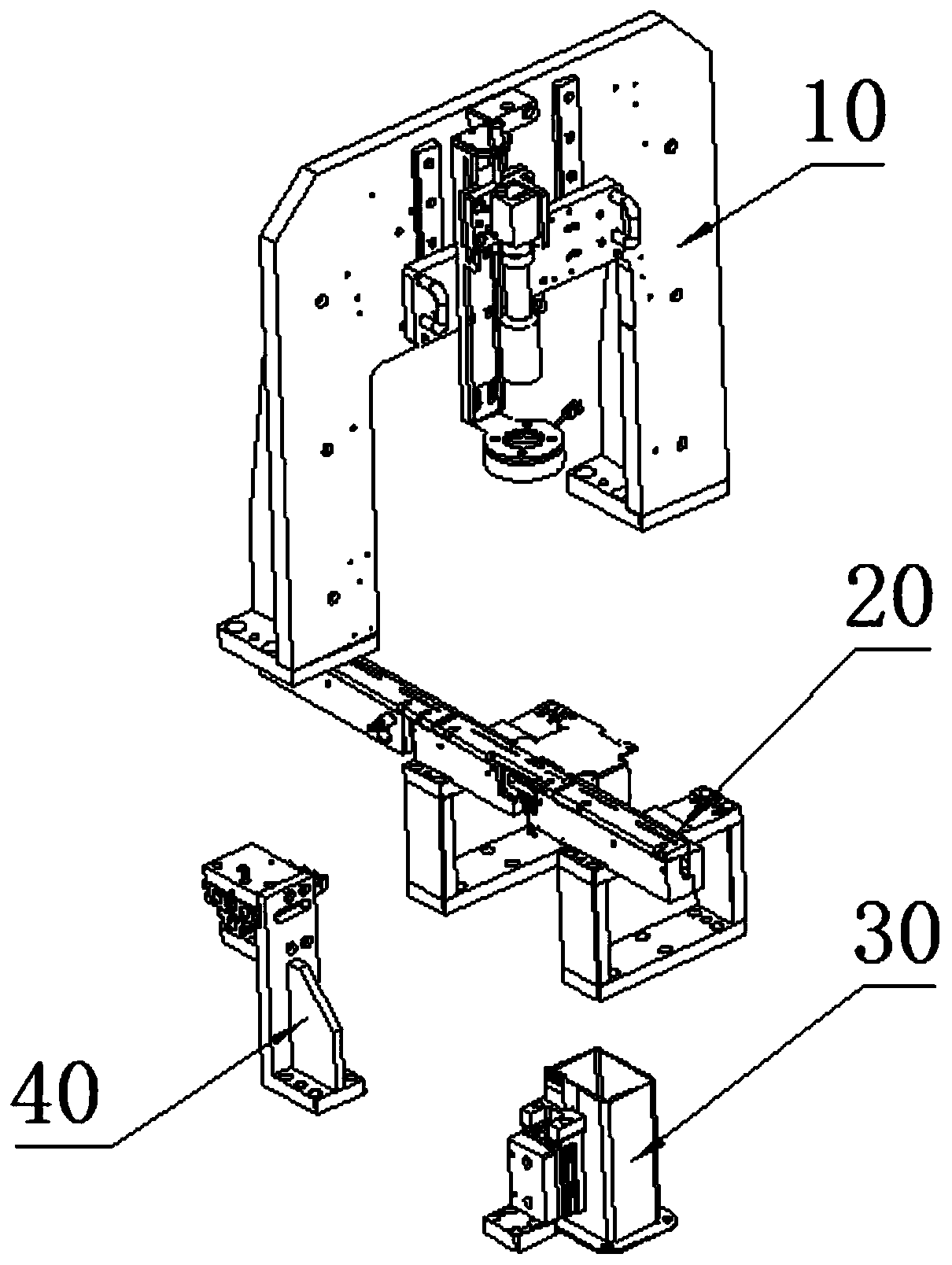

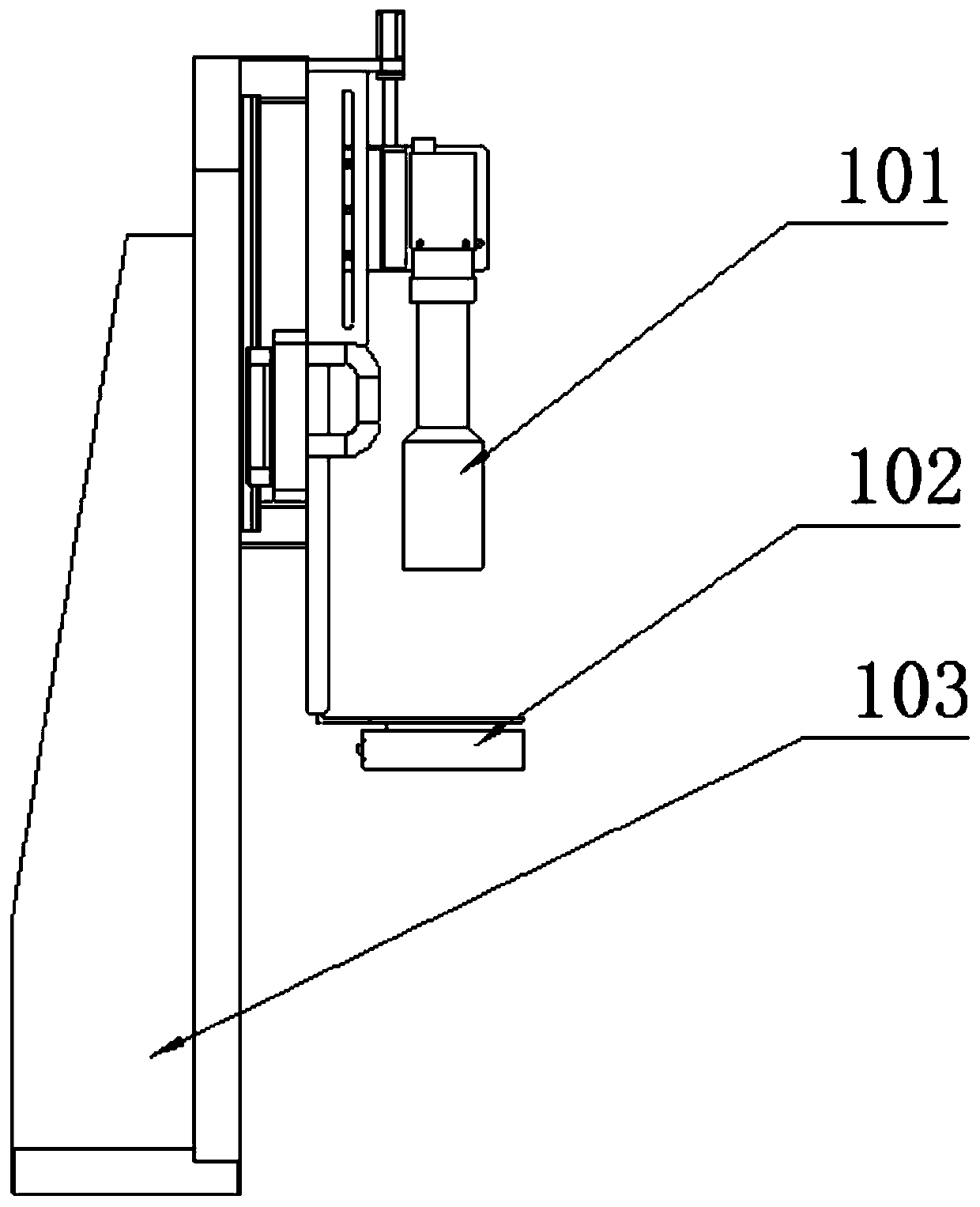

[0030] Such as Figure 7 As shown, during assembly, a feeding mechanism is provided under the detection fixing seat of the detection mechanism, and the feeding channel of the feeding mechanism is set overhead through the feeding fixing seat; a detection gap is set at the position of the feeding material channel below the camera on the detection fixing seat, and the detection gap tops The surface is used for taking photos with the camera, and the side of the detection gap is provided with a material distribution fixing seat of the material distribution mechanism. The material distribution fixing seat is respectively equipped with a first material distribution cylinder, a second material distribution cylinder, a positioning The cylinder, the first material distribution cylinder, the second material distribution cylinder, and the piston rod of the positioning cylinder are respectively provided with a first blocking block, a second blocking block, and a positioning block. The othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com