Quick starting joint

A quick start and joint technology, which is applied to aircraft parts, ejection/off-aircraft devices, launch devices, etc., can solve the problems of not being airtight, soft lock pin elongation, sticking, etc., and achieve the effect of ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below.

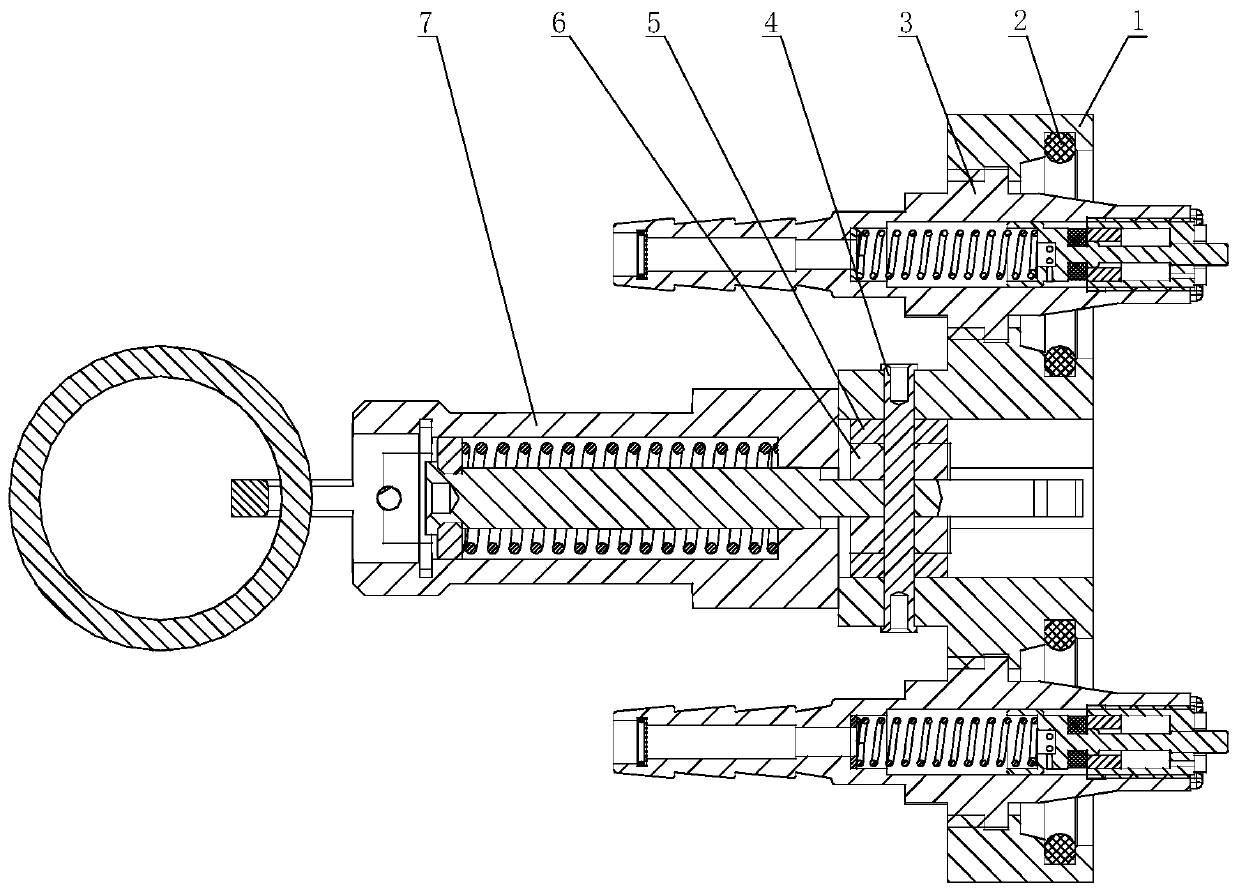

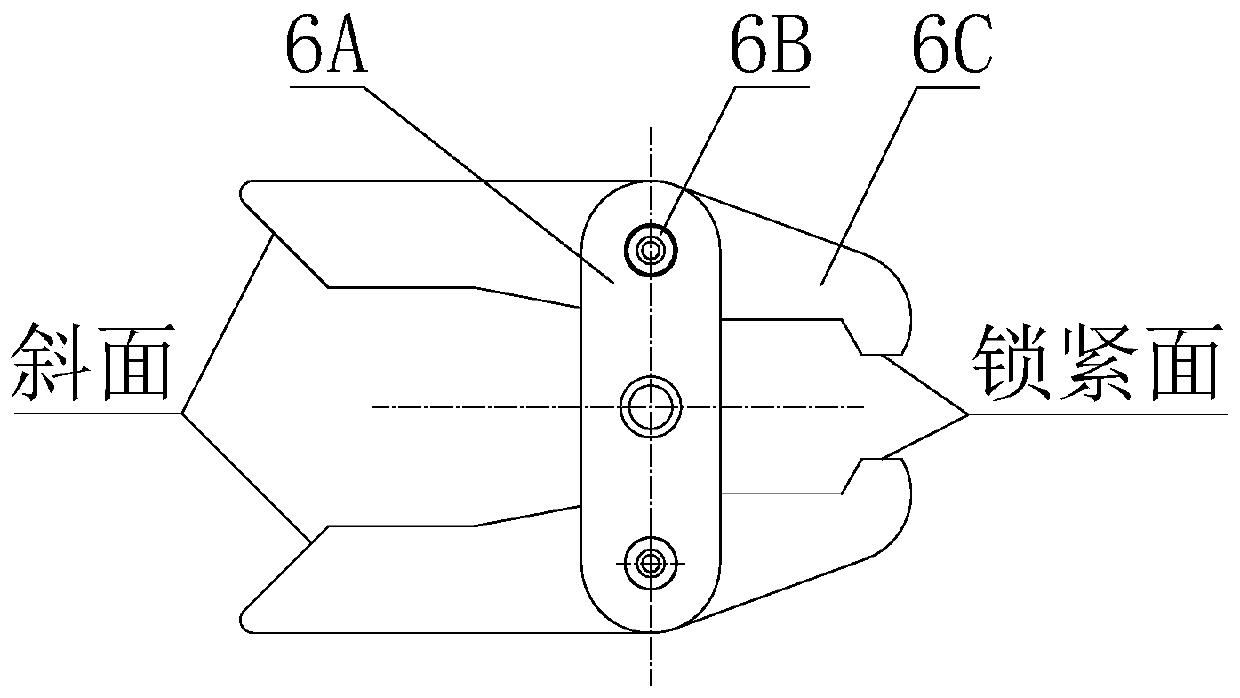

[0028] figure 1 is a schematic diagram of the quick start joint structure, such as figure 1 As shown, this embodiment provides a quick-start joint, including a joint seat, a nozzle assembly, a claw assembly, a pull rod assembly, etc., and an O-ring 2, a nozzle assembly 3, and a pin 4 are installed on the joint seat 1. Washer 5, claw assembly 6, pull rod assembly 7.

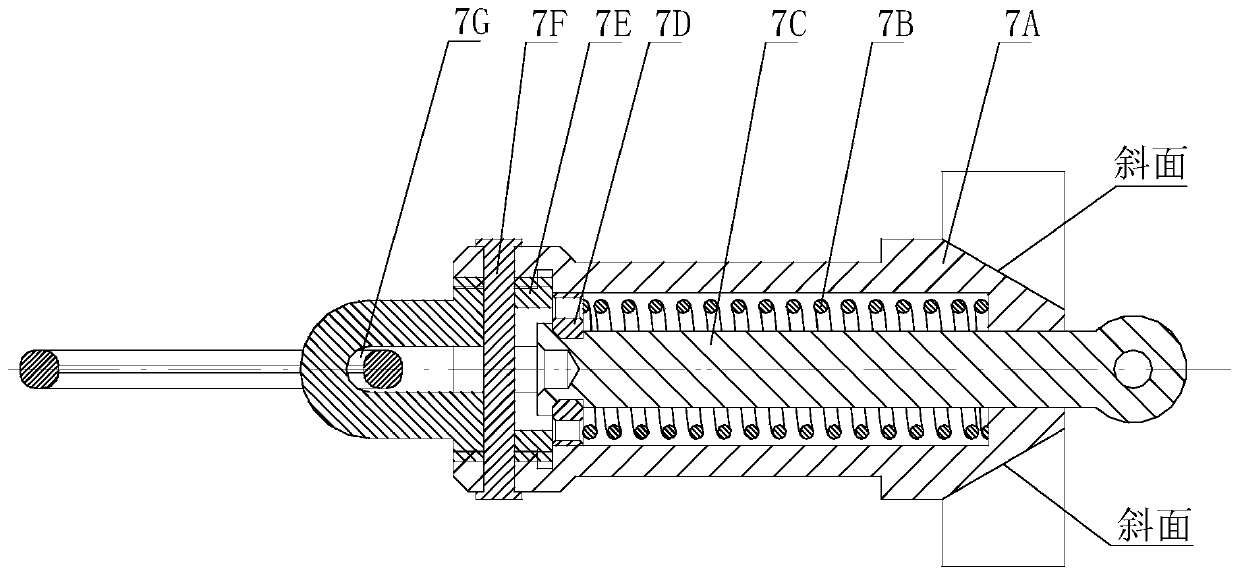

[0029] in, figure 2 is a schematic diagram of the tie rod assembly, combined with figure 1 with figure 2 As shown, the pull rod assembly 7 includes a sleeve 7A, a spring 7B, a pull rod 7C, a washer 7D, a special screw 7E, a pin 7F, and a joint ring 7G.

[0030] The sleeve 7A is a circular sleeve structure, with a stepped hole in the center to guide the gasket 7D, the spring 7B and the pull rod 7C respectively. inclined plane. The pull rod 7C is a cylindrical surface, and the front end is provided with a symmetrical milled and flatte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com