Pulley block

A pulley block and pulley technology, applied in portable lifting devices, winch devices, etc., can solve the problems of slider damage, difficulty in cleaning debris, debris stuck, etc., and achieve the effect of convenient use and not easy to hide dirt and evil people and practices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

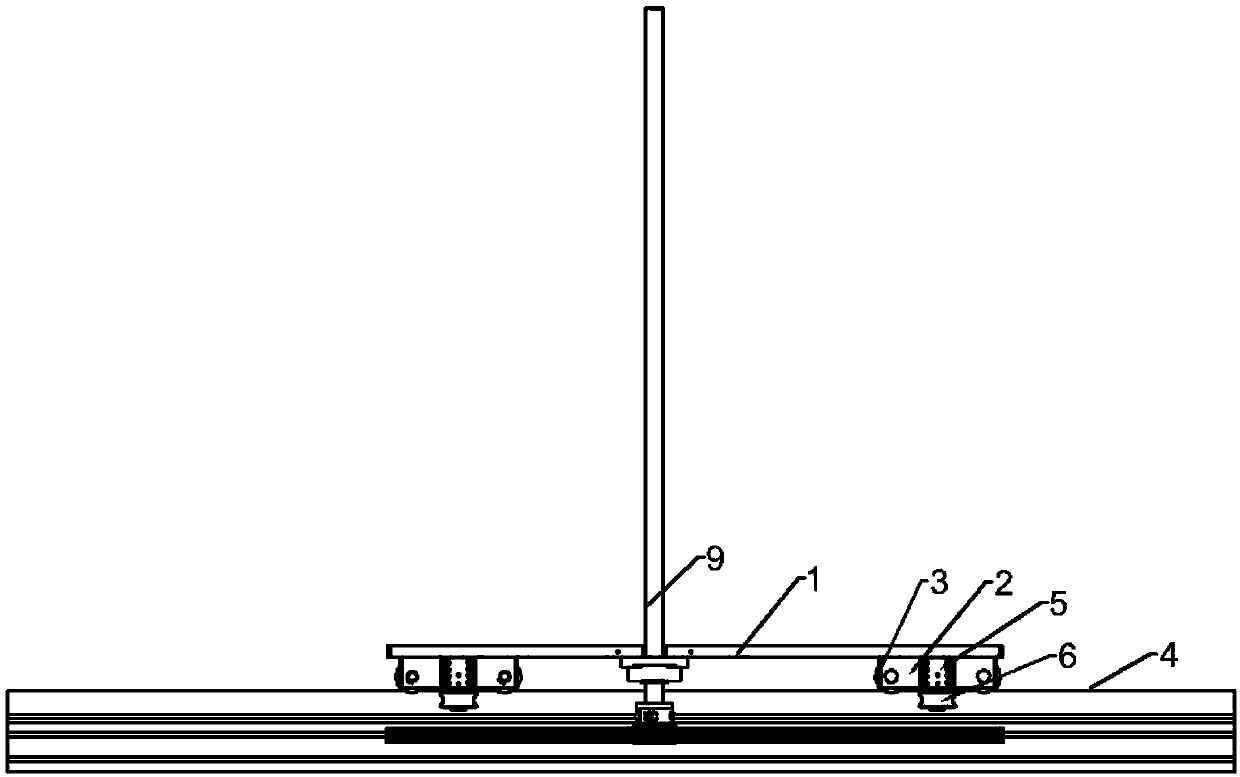

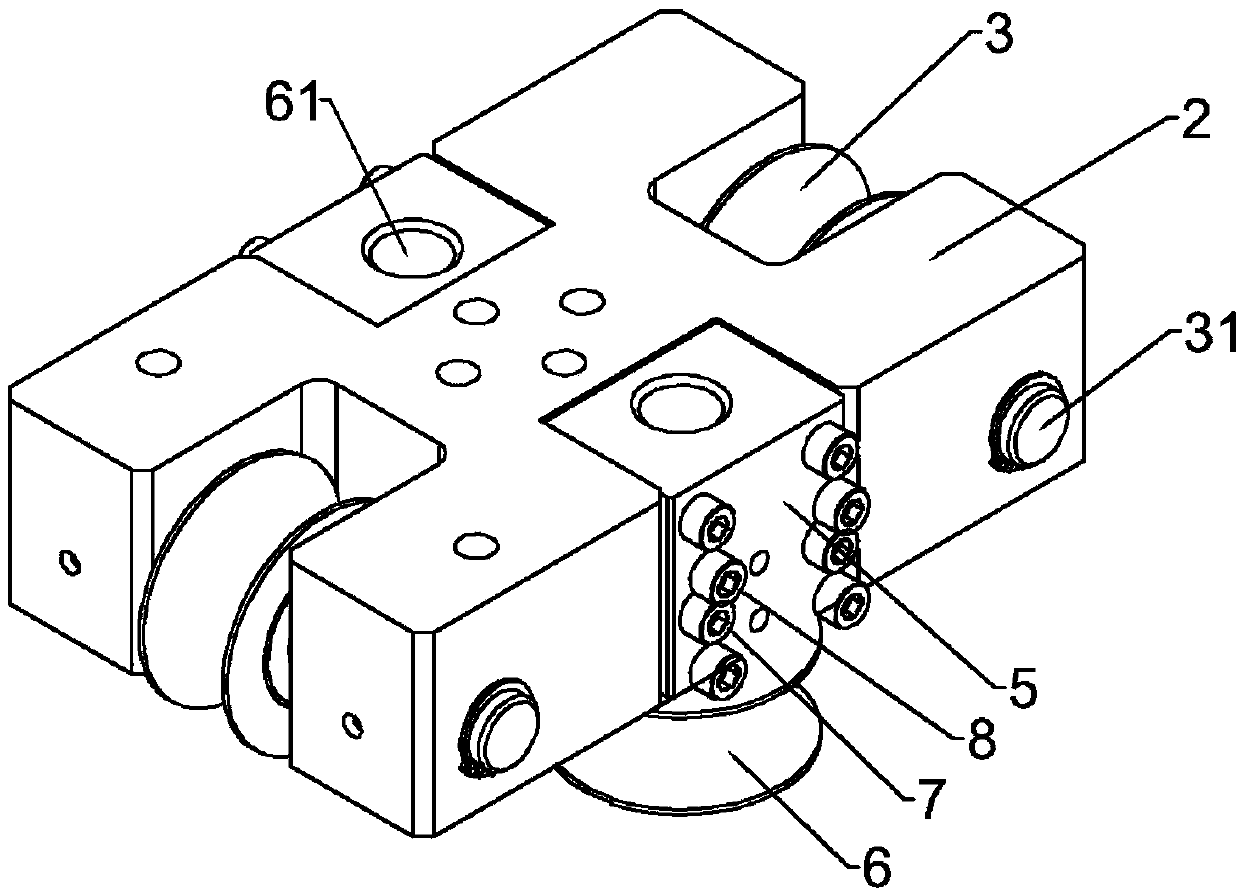

[0018] Example 1: Please refer to Figure 1-3 , a pulley block, including a pulley fixing frame 2 fixed on the left and right sides below the fixing plate 1, the left and right sides of the pulley fixing frame 2 are horizontally symmetrically rotated and connected with a longitudinal pulley 3, and the longitudinal pulley 3 is slidingly connected to the metal guide rail 4 , the front and rear sides of the pulley holder 2 are fixedly connected with a pulley adjustment block 5 that is adjustable in the vertical direction relative to the metal guide rail 4, and the pulley adjustment block 5 is rotatably connected with a horizontal pulley 6 that is slidably matched with the metal guide rail 4 through a lateral bearing 61.

[0019] The pulley adjustment blocks 5 on the front and rear sides are symmetrical to each other.

[0020] The longitudinal pulley 3 is rotatably connected through a longitudinal bearing 31 passing through the pulley fixing frame 2 .

[0021] A drive shaft 9 is ...

Embodiment 2

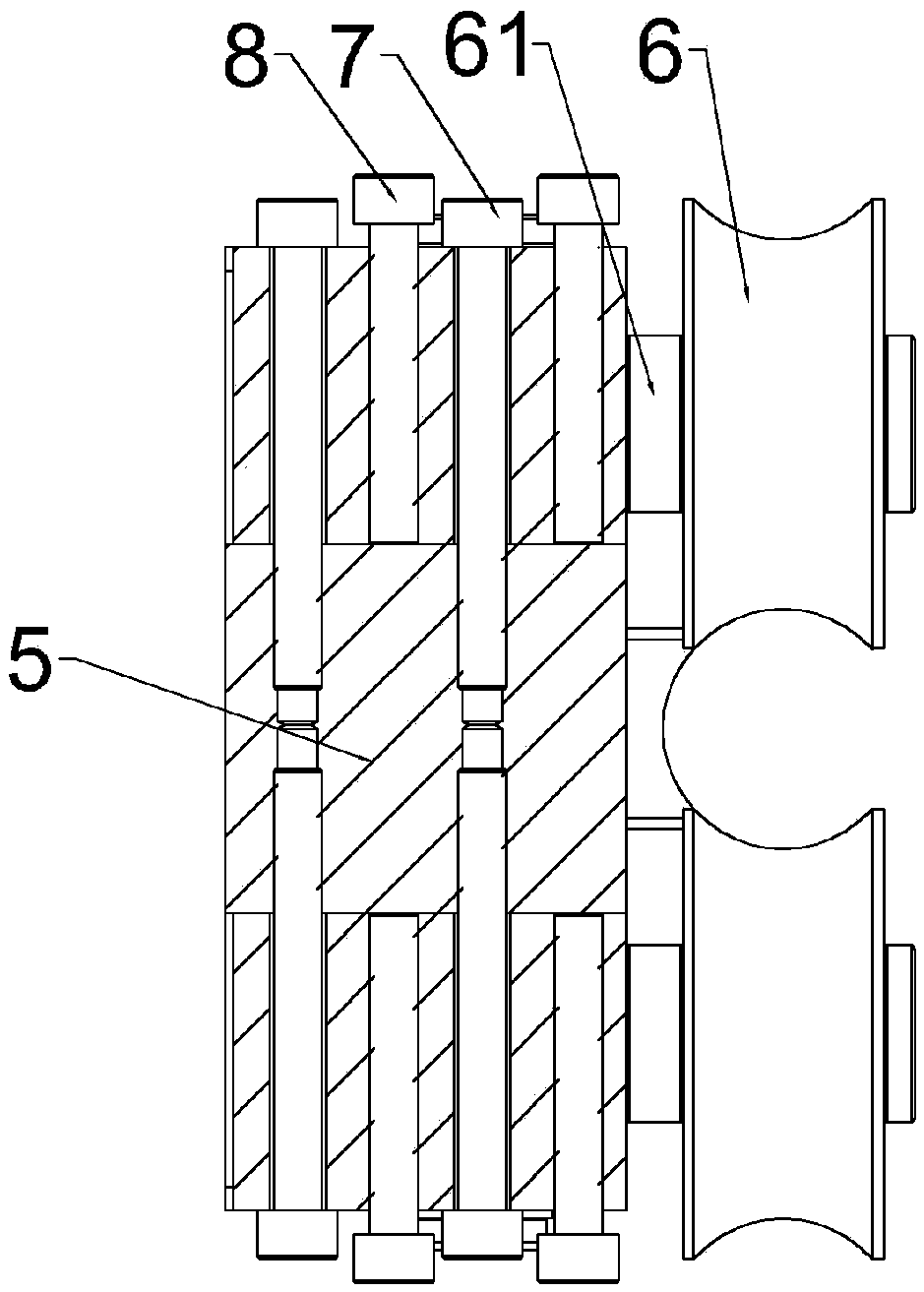

[0022] Embodiment 2: The difference between this embodiment and the previous embodiment is that the pulley adjusting block 5 is connected with the pulley fixing frame 2 through the fixing screw 7 threadedly connected with the pulley fixing frame 2, and the pulley adjusting block 5 slides relative to the fixing screw 7 Connection, the top surface screw 8 is threaded on the pulley adjustment block 5, and the top surface screw 8 offsets against the outer surface of the pulley holder 2. In this embodiment, an adjustment structure of the pulley adjustment block 5 is specifically given, which is simpler and more convenient to adjust the pulley adjustment block 5. In addition, the pulley adjustment block can also be adjusted by other adjustment methods, such as the pulley adjustment block 5 Be connected with bolt rotation, and the mode that bolt inner end is threaded with pulley fixed frame 2 also can.

[0023] Among them, the adjustment principle of the fixing screw 7 and the top sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com