Method for predicting falling head of combustion cone based on cigarette axial density

A technology of burning cones and cigarettes, applied in prediction, neural learning methods, biological neural network models, etc., can solve problems such as long detection period, large amount of smoke, large sample size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

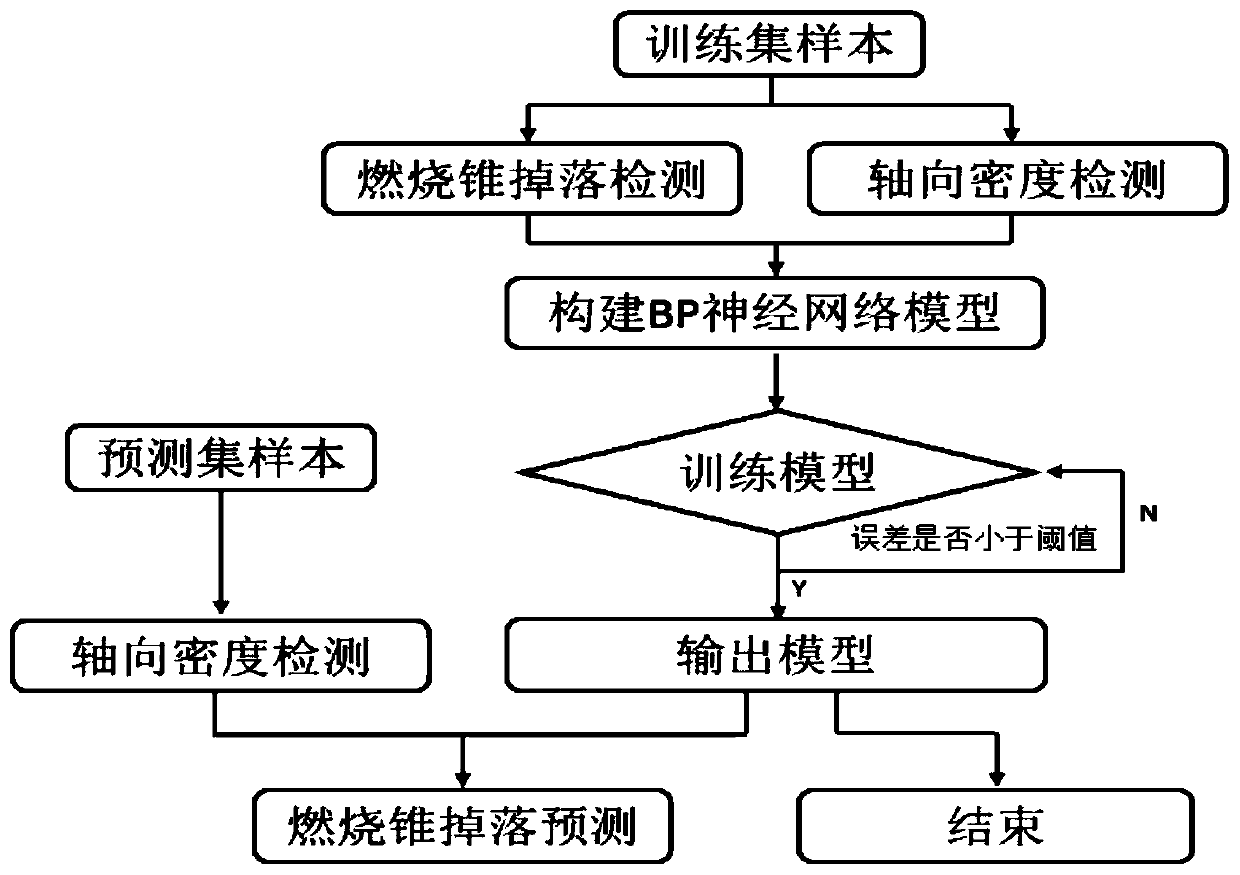

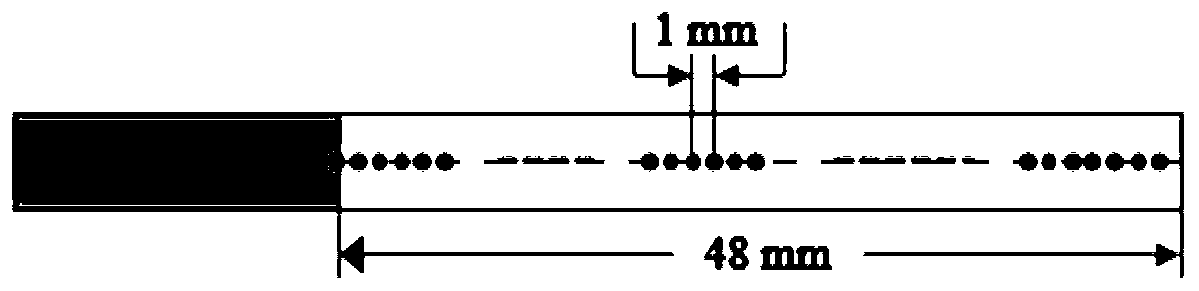

[0086] Attached below Figure 1-2 An embodiment of the present invention is described so as to clearly and completely describe the technical solution. Obviously, the described embodiment is only a part of the embodiments of the present invention, rather than all the embodiments.

[0087] A method for predicting combustion cone drop based on the axial density of cigarettes, comprising the following steps:

[0088] 1) Randomly select cigarettes with a sample size a=500 from a cigarette machine of a certain brand;

[0089] 2) Put the selected samples into a balanced environment for balancing; specifically, the balanced environment is the balanced environment specified in GB / T16447-2004, and the balanced time is 48h;

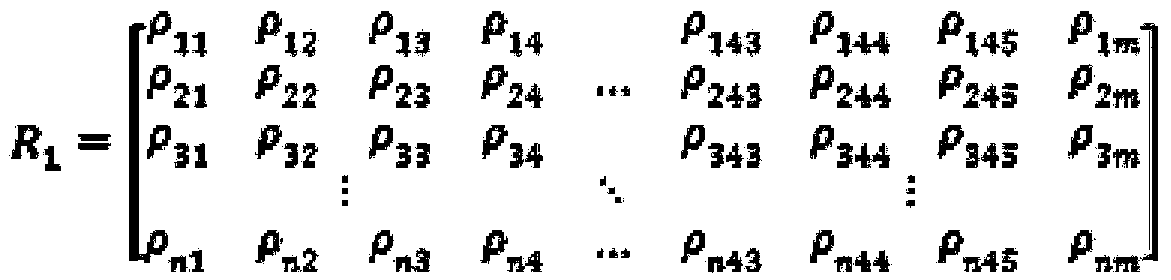

[0090] 3) 500 cigarettes after balancing are randomly selected and divided into training set samples and prediction set samples, wherein the number of cigarettes in the training set samples is n=300, and the number of cigarettes in the prediction set samples is b=2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com