An Improved Stranded Skeleton Equipment for High Precision Cables

A high-precision, improved technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of poor precision of the core wire limit fixing structure, easy shaking of the core wire, etc., and achieve a reasonable and effective limit fixing structure. Easy disassembly and maintenance, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

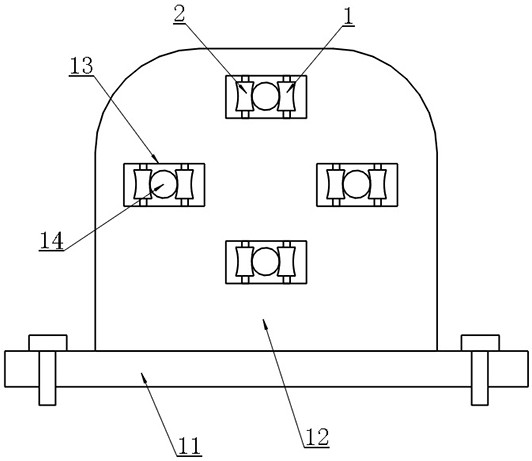

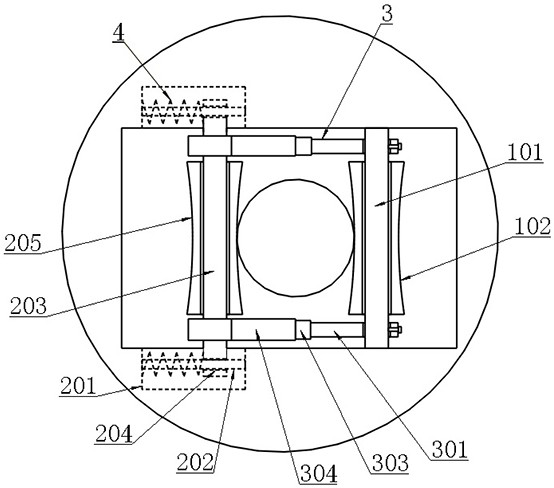

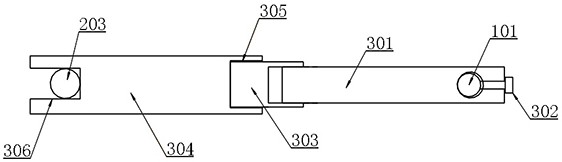

[0023] Example: as attached figure 1 , 2 , 3, 4 and attached Figure 5 As shown, an improved stranded skeleton equipment for high-precision cables includes a bottom plate 11, a skeleton vertical plate 12, and core wire openings 13, and also includes And the fixed wheel unit 1 and the movable wheel unit 2 for clamping the cable core wire 14 are arranged on the fixed wheel unit 1 and are used to limit the movement of the cable core wire by supporting the movable wheel unit 2. 14 minimum clamping width of the limit rod unit 3, and set on the core wire opening 13 and push the movable wheel unit 2 by elastic force to adjust the cable in the manner of the movable wheel unit 2 The spring jacking unit 4 of the clamping force of the core wire 14.

[0024] In this embodiment, the number of the core wire openings 13 is 4, and after the position is selected according to the cable twisting method, the clamping action of the fixed wheel unit 1 and the movable wheel unit 2 ensures that T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com