Cooling point spray head for mold sliding block

A mold slider and nozzle technology, applied in the field of molds, can solve problems such as unfavorable production and processing, mold opening and closing restrictions, slider deformation, etc., and achieve the effect of improving cooling effect and increasing spray area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

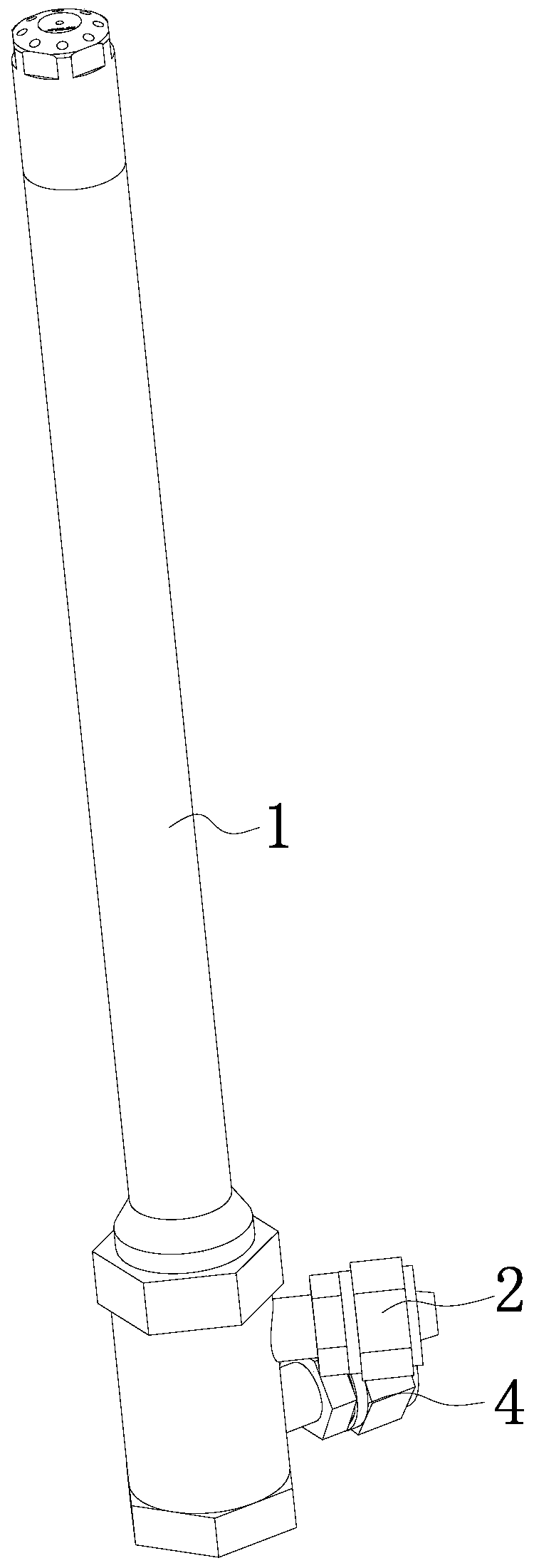

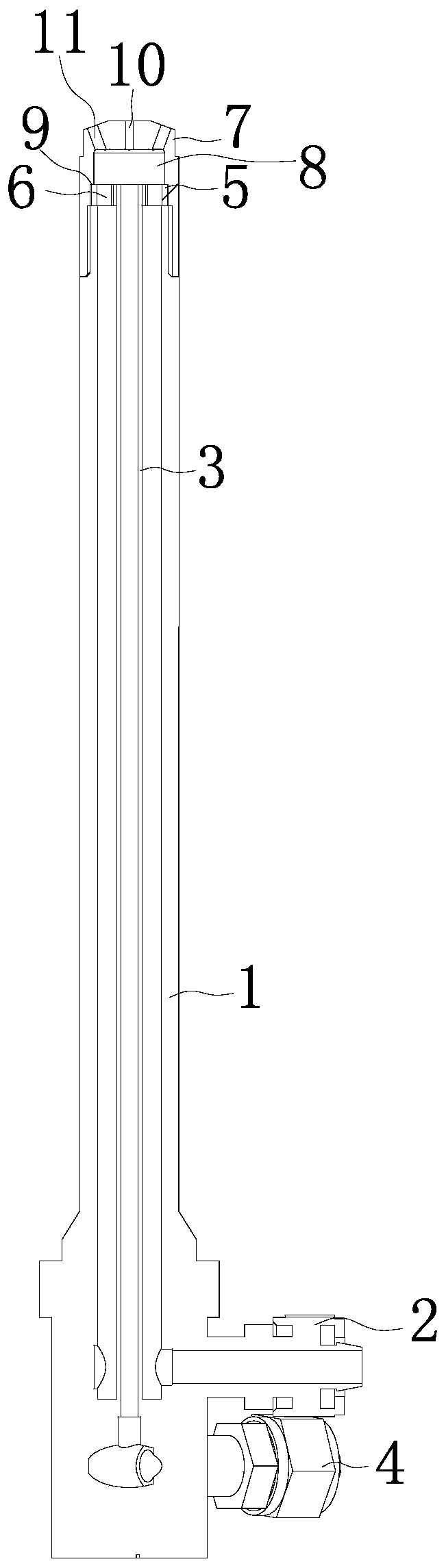

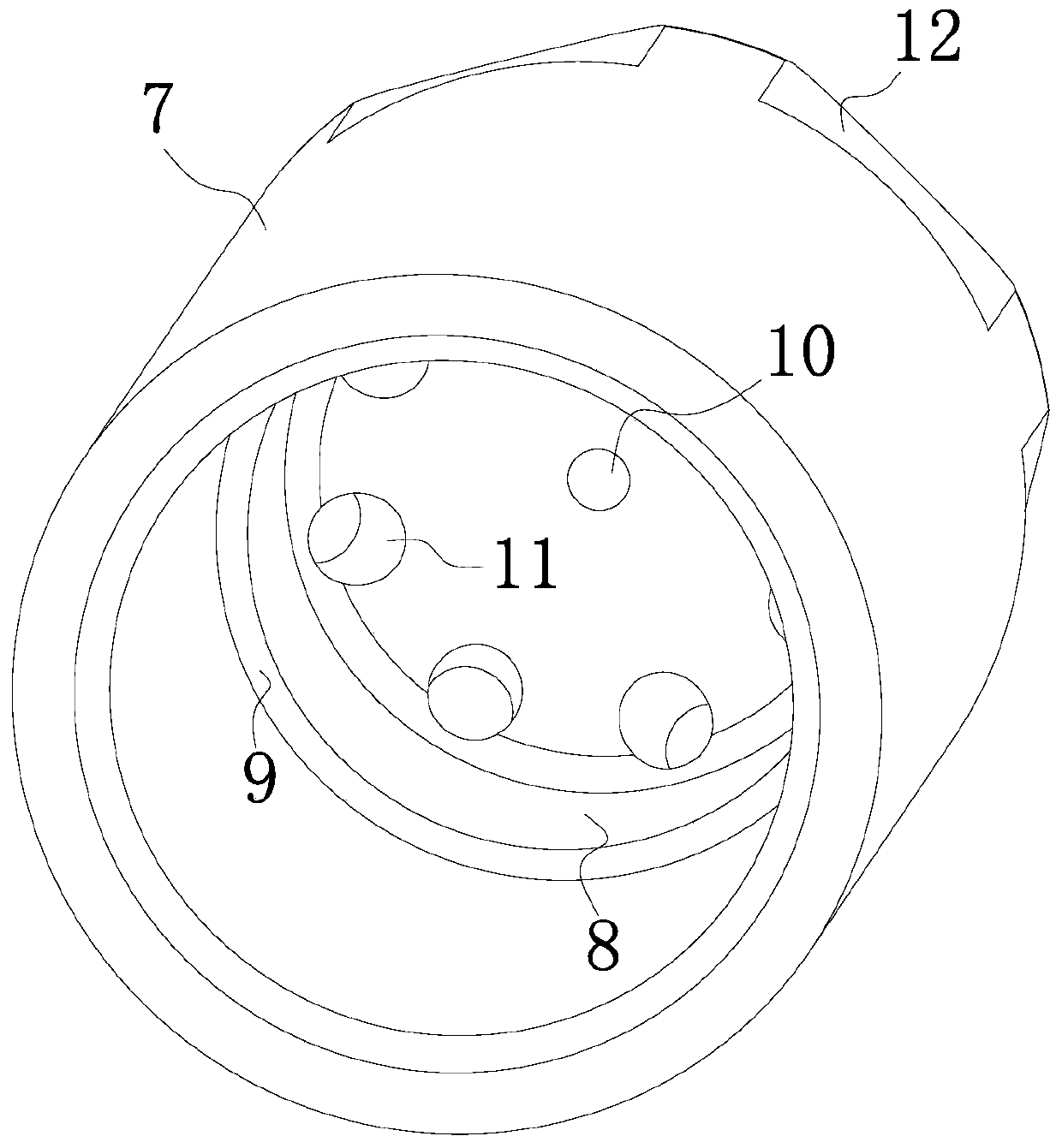

[0018] Such as Figure 1 to Figure 3 As shown, the nozzle used for the cooling point of the mold slider includes: a connecting pipe 1, which is a hollow structure, and the lower end of the connecting pipe 1 is provided with a water inlet valve 2; an air inlet pipe 3, which is inserted in the connecting pipe 1, and The outer diameter of the air pipe 3 is smaller than the inner diameter of the connecting pipe 1, and the lower end of the air inlet pipe 3 is provided with an air inlet valve 4; the water passage ring 5 is movably sleeved on the upper end of the air inlet pipe 3, and the lower end surface of the water passage ring 5 is movable against the connection pipe 1 On the end face, a number of water holes 6 are opened on the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com