A kind of cutting method of round steel pipe

A cutting method and technology for round steel pipes are applied in the cutting field of round steel pipes, which can solve the problems of potential safety hazards and the collapse of rods, and achieve the effects of improving cutting efficiency, ensuring safety and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

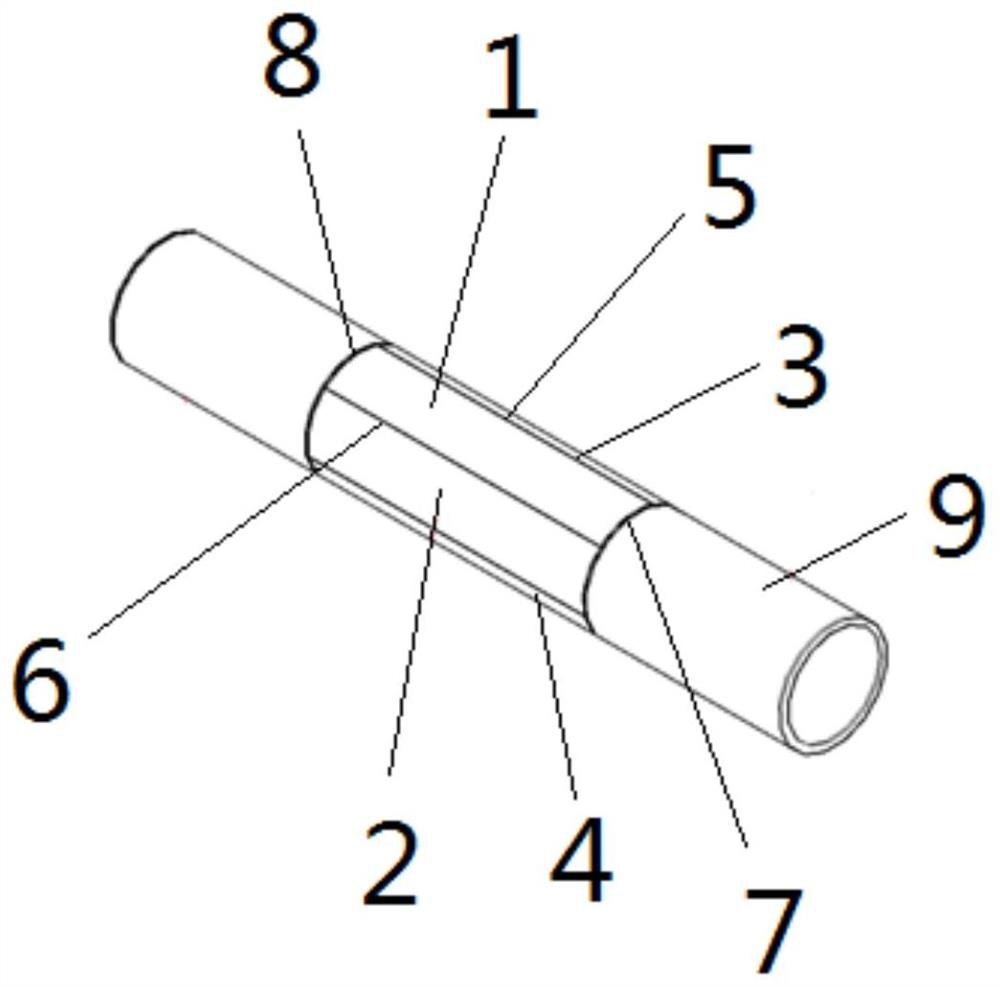

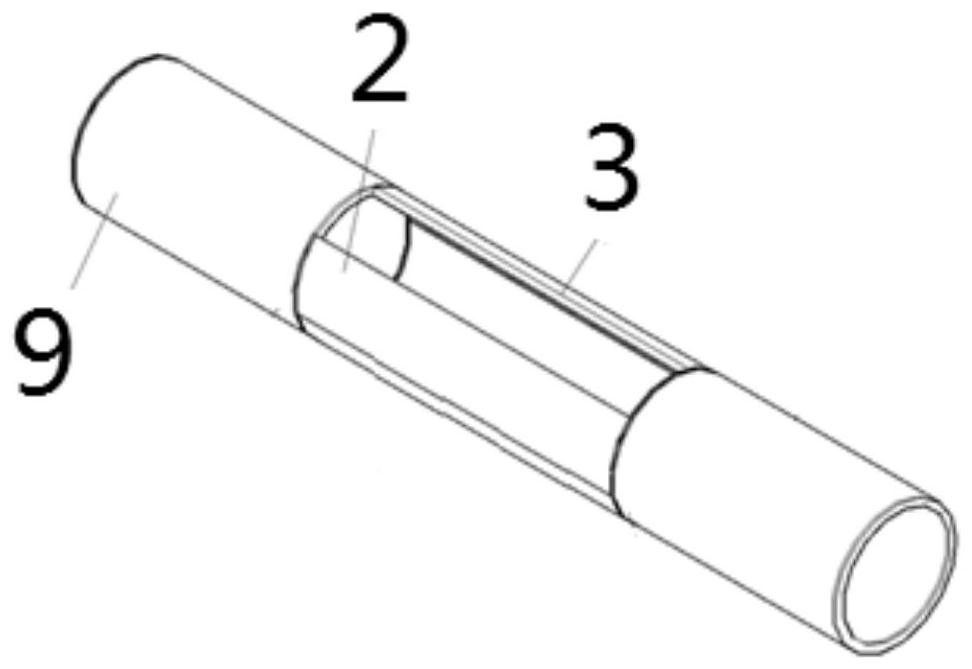

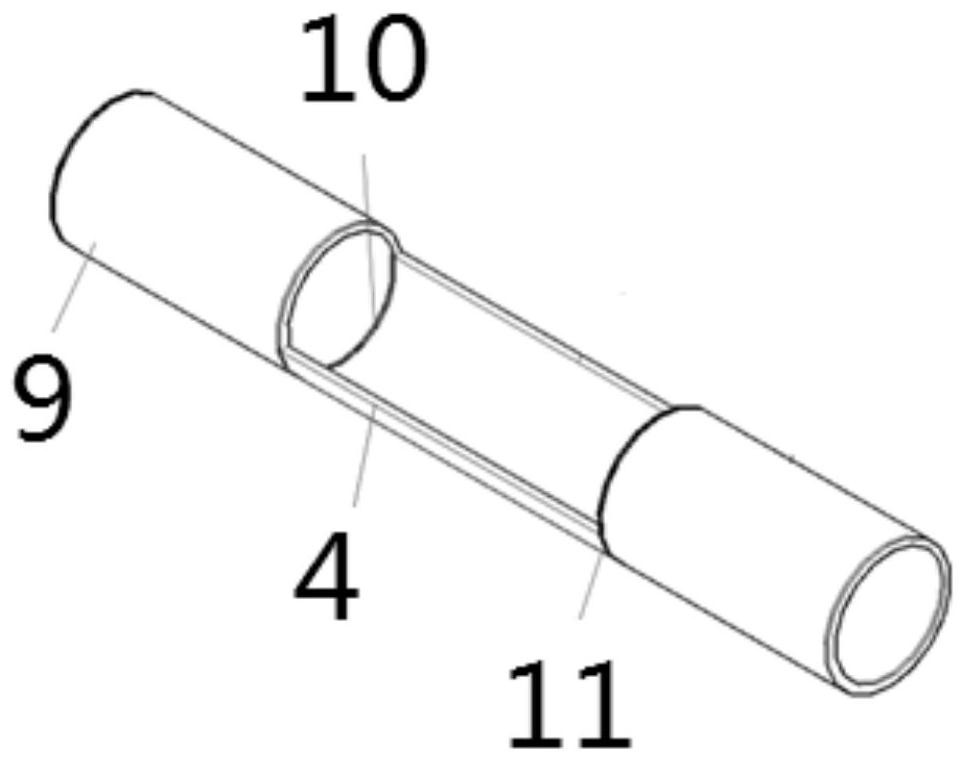

[0025] like Figure 1-3 A specific embodiment of the cutting method of the shown round steel pipe includes:

[0026] First, according to the cross-sectional size, thickness and bending deformation of the round steel pipe to be cut, the part of the round steel pipe to be cut is divided into four parts along its circumferential direction, and the projections of the four parts are all rectangles. Among them, the radian of the first part 1, the second part 2 and the third part 3 are all 60°, the radian of the fourth part 4 is 180°, and the second part 2 and the third part 3 are symmetrically distributed on the two sides of the first part 1 respectively. On the side, the fourth part 4 is arranged corresponding to the first part 1, the second part 2 and the third part 3, and is located at the bottom of the round steel pipe.

[0027] Then, the divided first part 1 round steel pipe is axially cut along the divided track, and after radial cutting is performed, the first part 1 round s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com