Multifunctional bulk material storage vehicle

A bulk material, multi-functional technology, applied in the direction of multi-axis trolleys, trolleys, motor vehicles, etc., can solve the problems of immovability, high equipment cost, large plant area, etc., to improve flexible mobility and ease of use performance, The effect of the maintenance and repair of the bottoming equipment in the later stage and the dependence of the bottoming labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

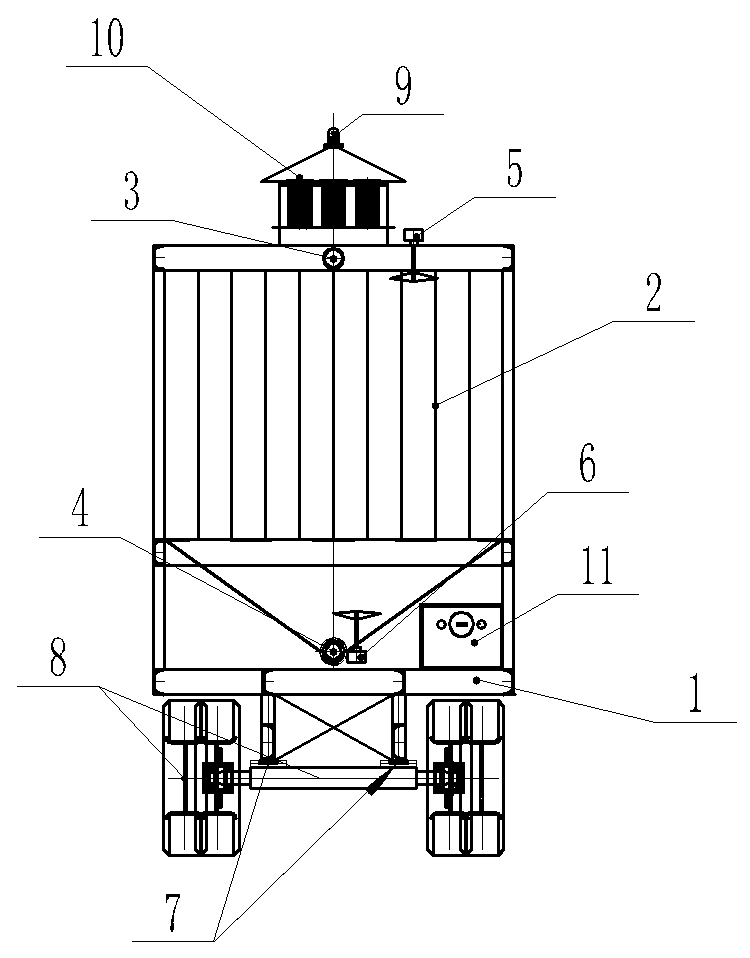

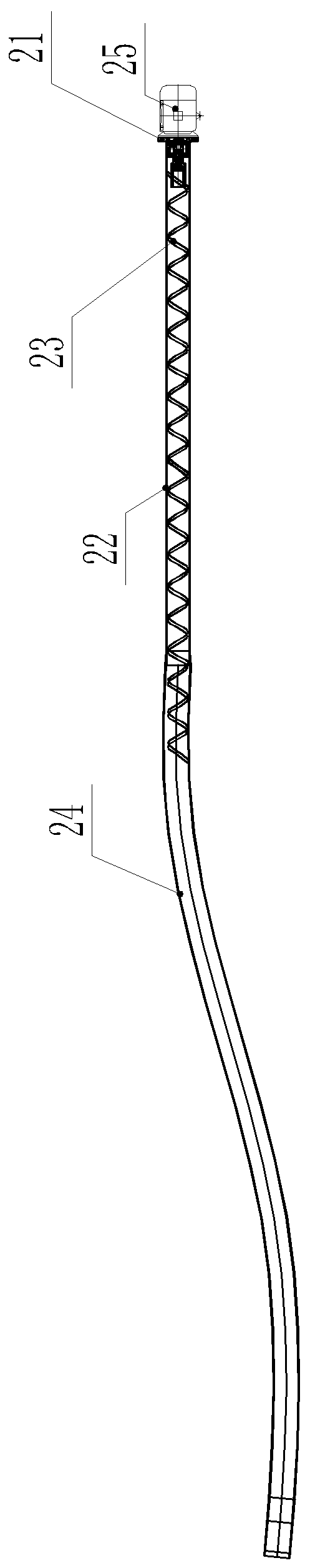

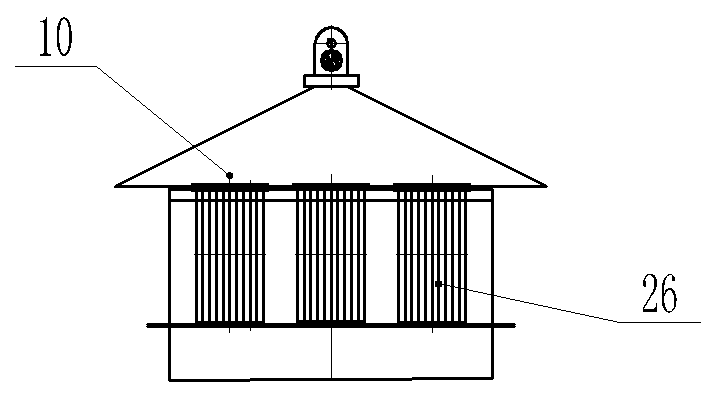

[0022] see figure 1 , figure 2 , image 3 , the multi-functional bulk material storage vehicle of the present invention comprises a vehicle frame 1 and a storage bin 2, the storage bin 2 and the vehicle frame are integrated or are movably installed on the vehicle frame 1, and a feeding device 3 is installed on the upper part of the storage bin 2 , the bottom of the storage bin 2 is equipped with a discharge device 4, the feed device 3 and the discharge device 4 are respectively composed of a motor transmission deceleration device 21, an inlet / discharge pipe 22, and an inlet / discharge nipple 23, and the motor transmission deceleration device 21 It is connected with the inlet / outlet material nip drive 23, which is matched and arranged in the inlet / outlet pipe 22; the power motor 25 of the feeding device 3 and the feeding device 4 is connected with the control device.

[0023] Such as image 3 As shown, the head / end of the inlet / outlet pipe 22 is respectively connected with a...

Embodiment 2

[0025] The multifunctional bulk material storage vehicle of this embodiment is different from Embodiment 1 in that: further, an upper material level device 5 is installed above the interior of the storage bin 2, and a lower material level device 6 is installed at the bottom. The output signals of device 5 and lower material level device 6 are connected to the control device.

Embodiment 3

[0027] The multifunctional bulk material storage vehicle of this embodiment differs from Embodiment 1 and Embodiment 2 in that: further,

[0028] Between the storage bin 2 and the vehicle frame, between the vehicle frame and its walking and steering device 8, or between the storage bin (integrated with the vehicle frame) and the walking and steering device 8, a load cell 7 is provided; the load cell The output signal is connected to the control device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com