Chamber seal assembly and growth furnace

A technology for sealing components and chambers, used in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of difficult removal of furnace flanges, damage to the reaction chamber, and increase of the chamber pressure rise rate, so as to avoid damage. The risk of the reaction chamber, the requirement to ensure the pressure rise rate, and the effect of improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the chamber sealing assembly and growth furnace provided by the present invention will be described in detail below with reference to the accompanying drawings.

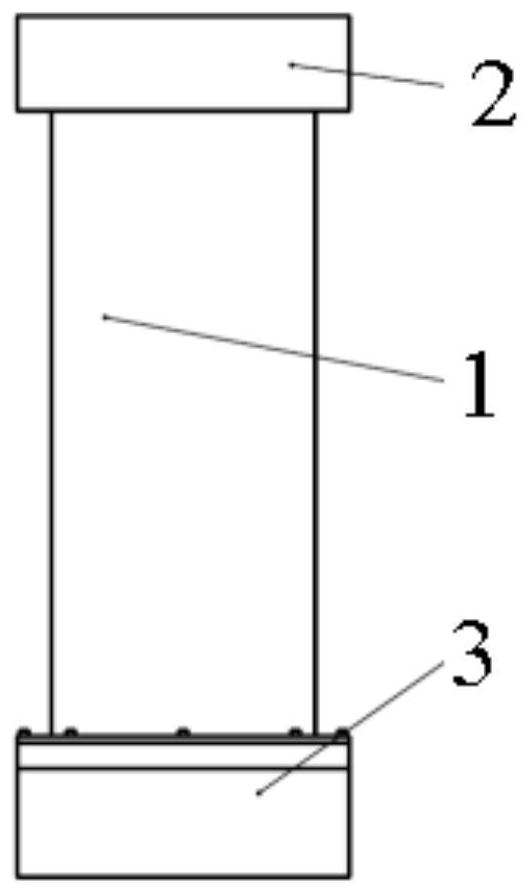

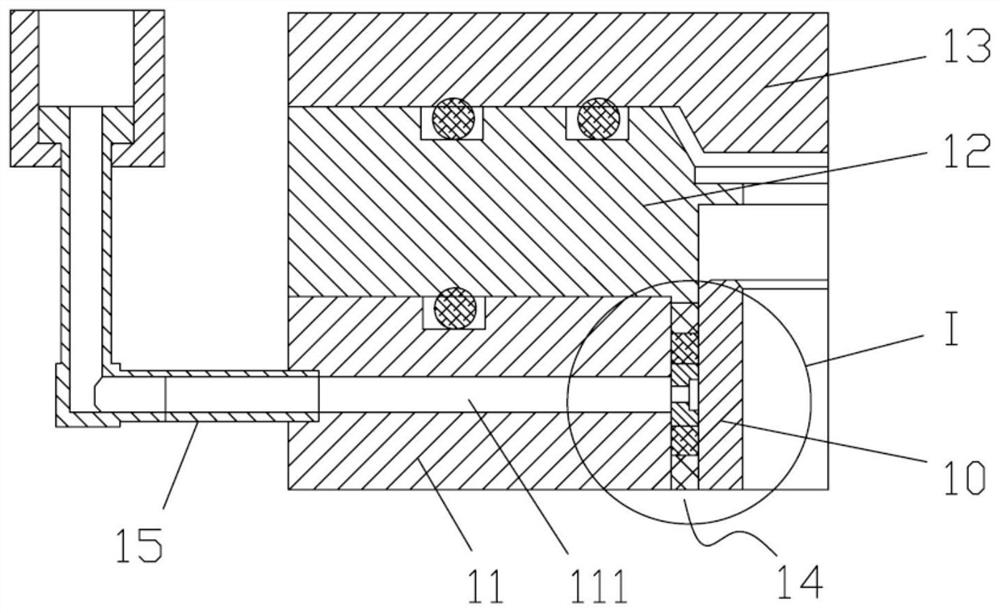

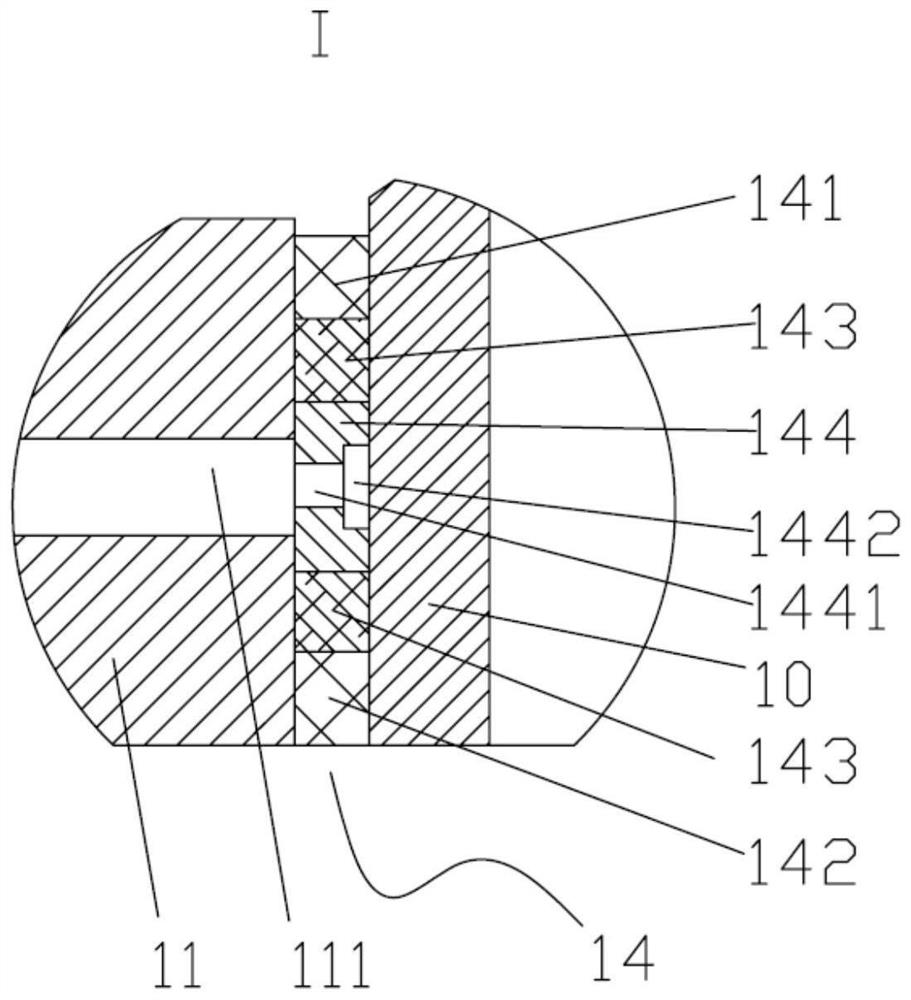

[0030] see figure 1 , is a partial cross-sectional view of the growth furnace used in the embodiment of the present invention. The growth furnace includes a reaction chamber 10 , an upper chamber and a lower chamber, and the upper chamber and the lower chamber are sheathed on the reaction chamber 10 from the upper end and the lower end of the reaction chamber 10 respectively. figure 1 Only a partial cross-sectional view of the upper furnace and its sealing structure with the reaction chamber 10 is shown. Since the sealing structure between the lower furnace and the reaction chamber 10 is similar to the sealing structure between the upper furnace and the reaction chamber 10 , this embodiment only t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com