Detachable motor mounting structure with protection function and mounting method thereof

A protection function and installation structure technology, applied in the field of detachable motor installation structure, can solve the problems of inability to protect the motor, inconvenient maintenance work, difficult disassembly, etc., and achieve the effects of improving maintenance and disassembly efficiency, improving support effect, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

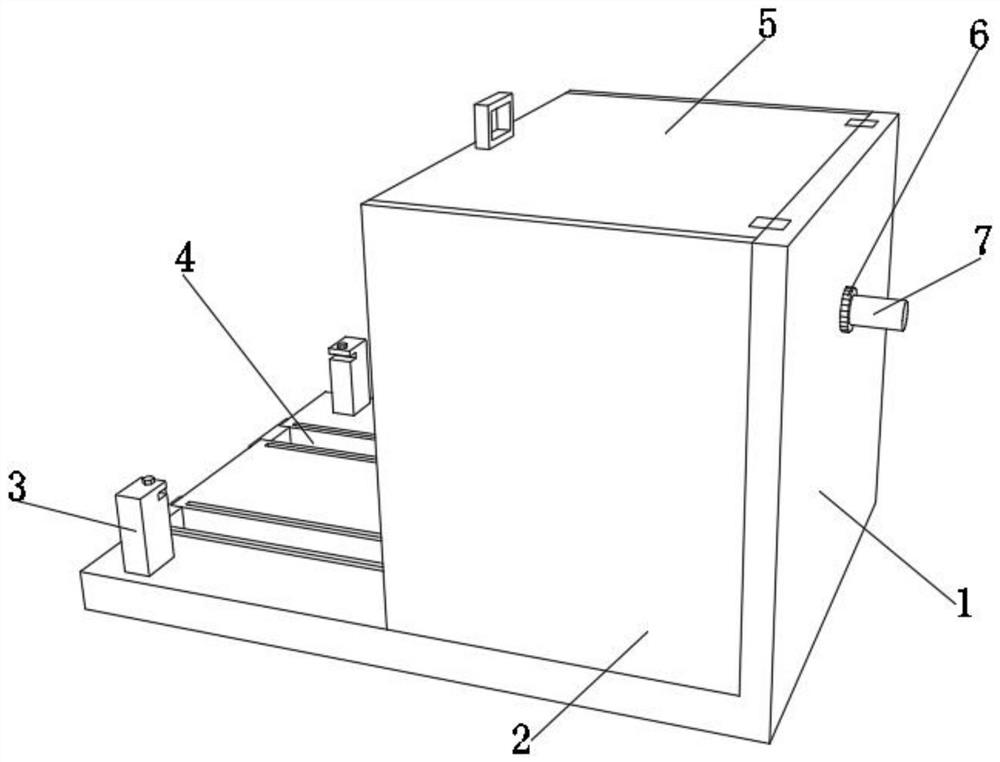

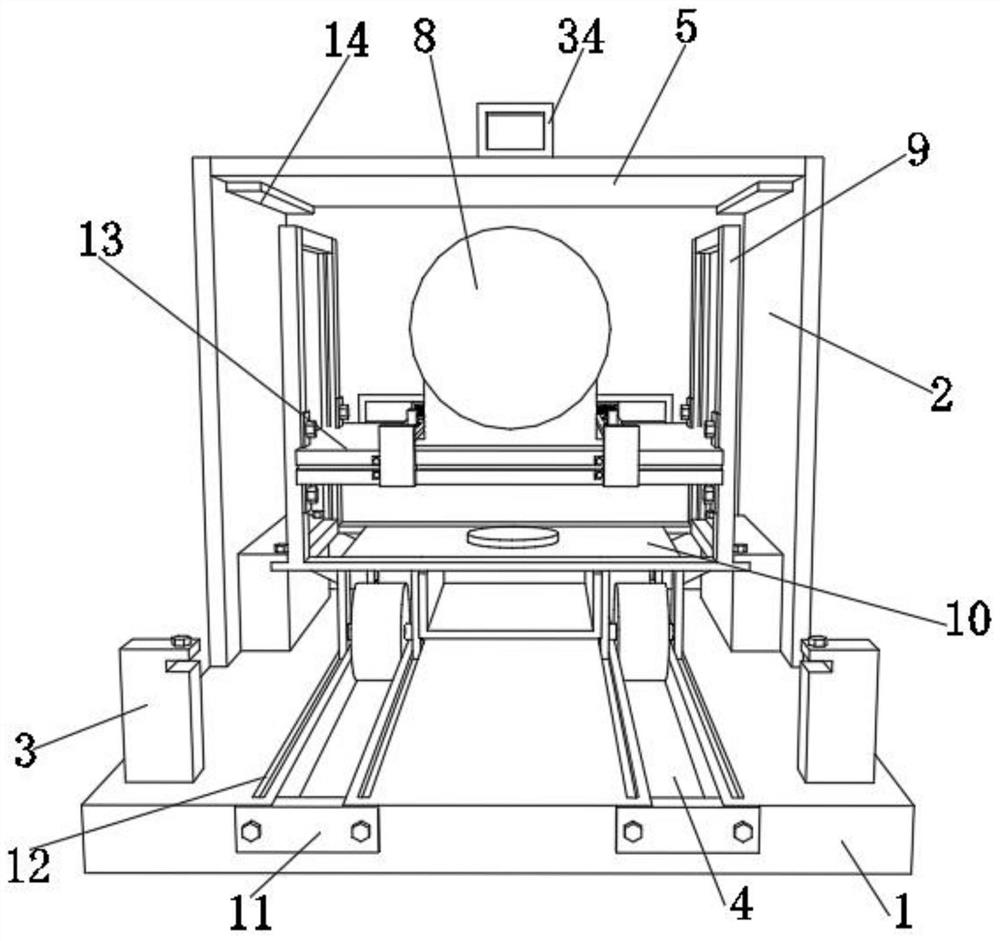

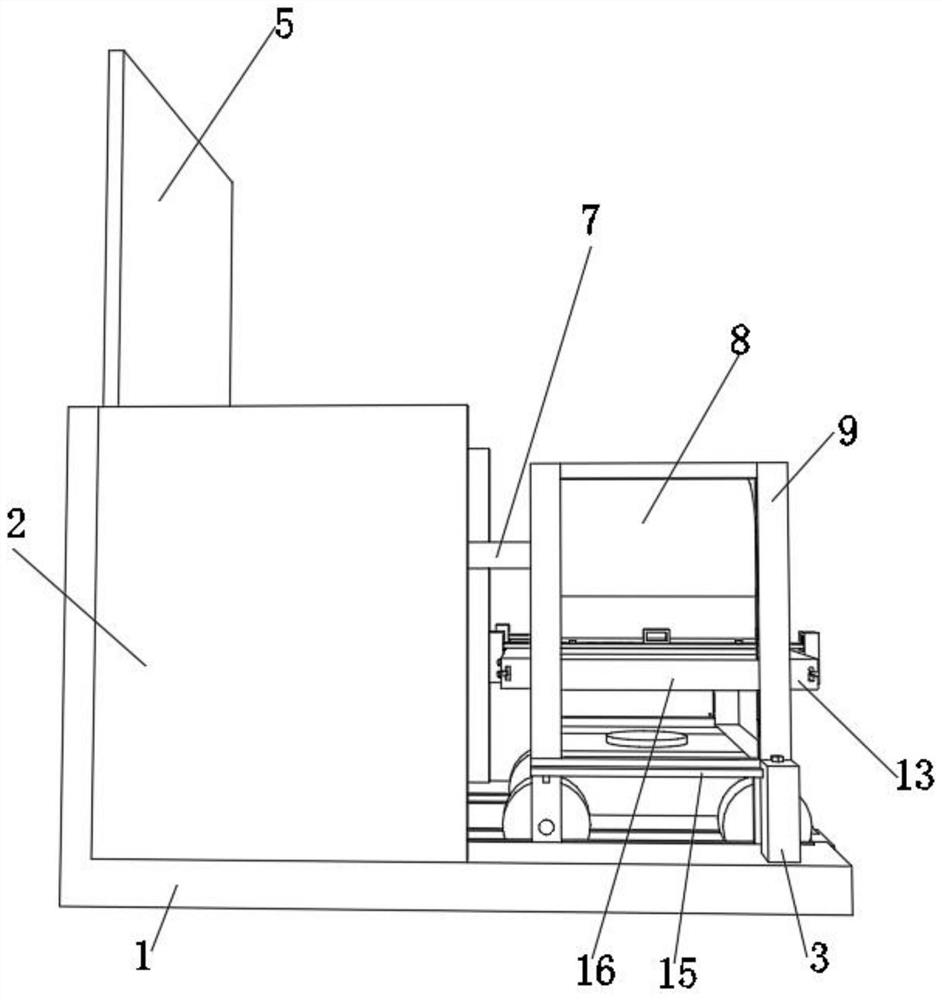

[0043] A detachable motor installation structure with protective function, such as Figure 1-7 As shown, it includes an L-shaped fixed plate 1, the outer wall of one side of the L-shaped fixed plate 1 is provided with two side baffles 2, the top outer wall of the L-shaped fixed plate 1 is fixed with a top cover 5 through a hinge, and the top outer wall of the top cover 5 A second handle 34 is provided, two support blocks 14 are respectively provided on the outer wall of one side of the two side baffles 2, two pulley tracks 4 are arranged on the outer wall of one side of the L-shaped fixed plate 1, and four inner walls of the four pulley tracks 4 are respectively provided with Four rollers 26, four rollers 26 top outer walls are provided with fixed frame 15, fixed frame 15 top outer walls are provided with two support frames 9, two support frames 9 side outer walls are provided with mounting plate 13, and mounting plate 13 top outer walls are provided with There is a motor base...

Embodiment 2

[0054] A method for installing a detachable motor installation structure with a protective function, comprising the following steps:

[0055] S1: first lift the top cover 5 through the second handle 34, and then unscrew the screws used to fix the fixing frame 15 on the two second positioning posts 19;

[0056] S2: pull out the fixing frame 15 by pulling the two supporting frames 9, and then fix the fixing frame 15 on the two first positioning columns 3 by screws;

[0057] S3: move the mounting plate 13 up and down to move the mounting plate 13 to a precise height, and then fix the position of the mounting plate 13 through the first fixing piece 20;

[0058] S4: Place the new motor 8 on the top outer wall of the mounting plate 13, and lift the two pressure plates 31 upward through the two first handles 28 with both hands;

[0059] S5: Both hands push the pressure plate 31 to move left and right through the two first handles 28, when the pressure plate 31 moves to the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com