Coaxial multi-layer multi-level center drive type electric drive system

A technology of electric drive system and central drive, which is applied in the direction of electric components, transmission devices, electromechanical devices, etc., can solve the problems of poor overall balance and complex structure of electric drive system, and achieve low manufacturing cost, compact structure and high safety factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

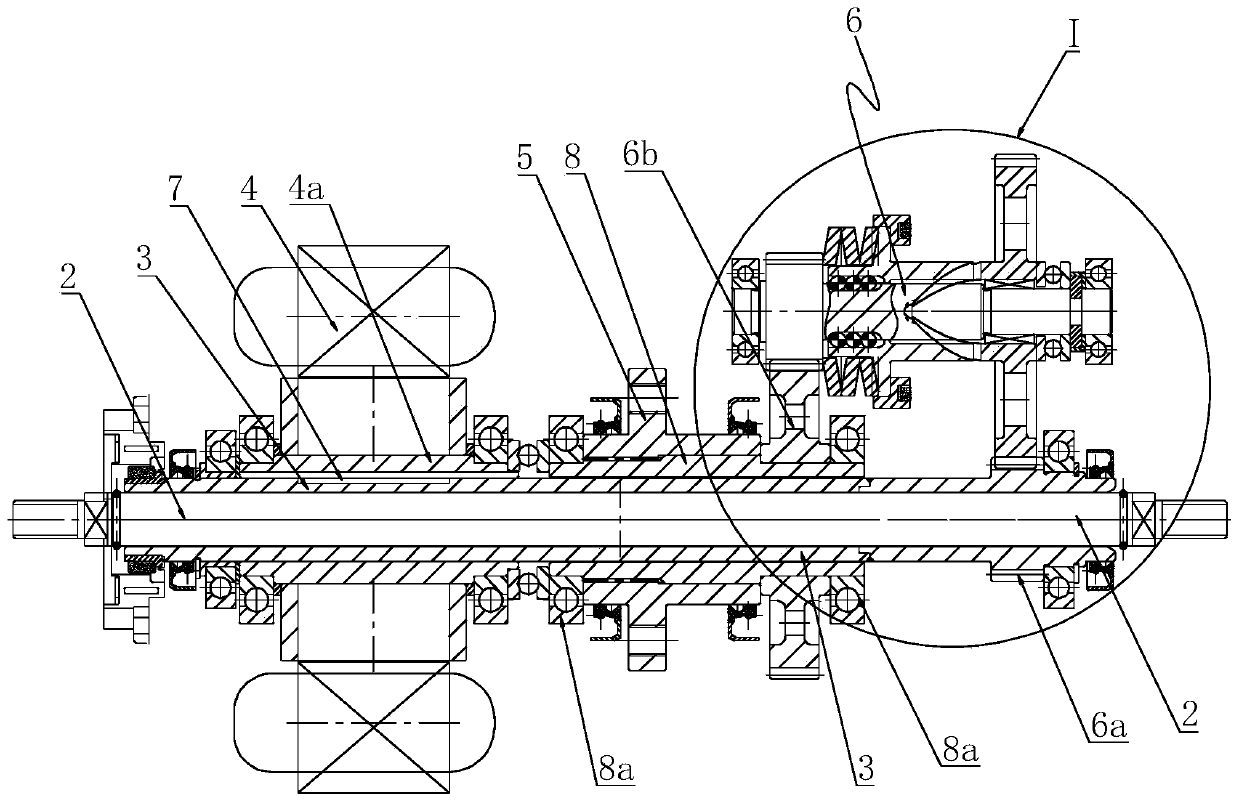

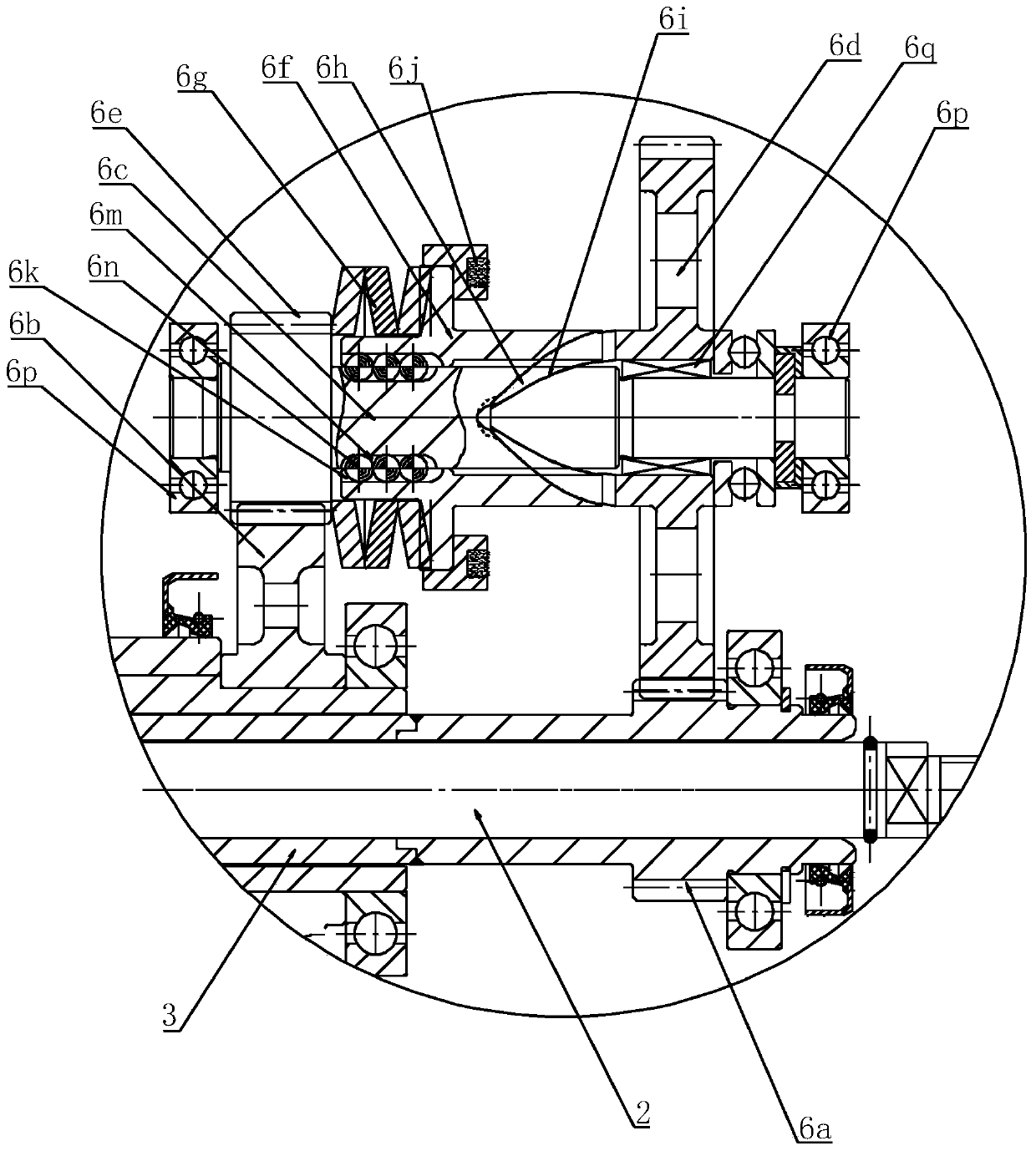

[0021] Such as figure 1 with 2 As shown, a coaxial multi-layer, multi-stage central drive type electric drive system includes a fixed shaft 2, which is used to support the entire electric drive system, and a rotating sleeve 3 extending along its length is sleeved on the fixed shaft 2. When the rotating sleeve 3 is working, it rotates relative to the fixed shaft 2. The rotating sleeve 3 is provided with a power source 4, an output component 5 and a reduction mechanism 6 in sequence from left to right. When the integrated electric drive system is working, the power source 4 drives the rotating sleeve. 3 rotation, the rotation speed of the rotating sleeve 3 is decelerated by the deceleration mechanism 6 to drive the output part 5 to rotate, that is, the effective power output is performed at the middle position of the electric drive system, and the setting of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com