Central drive electric drive system for electric two-wheeled vehicle

An electric drive system and central drive technology, applied in the direction of motor vehicles, electric components, motorcycles, etc., can solve the problems of poor overall balance and complex structure of the electric drive system, and achieve low manufacturing cost, compact structure and good balance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

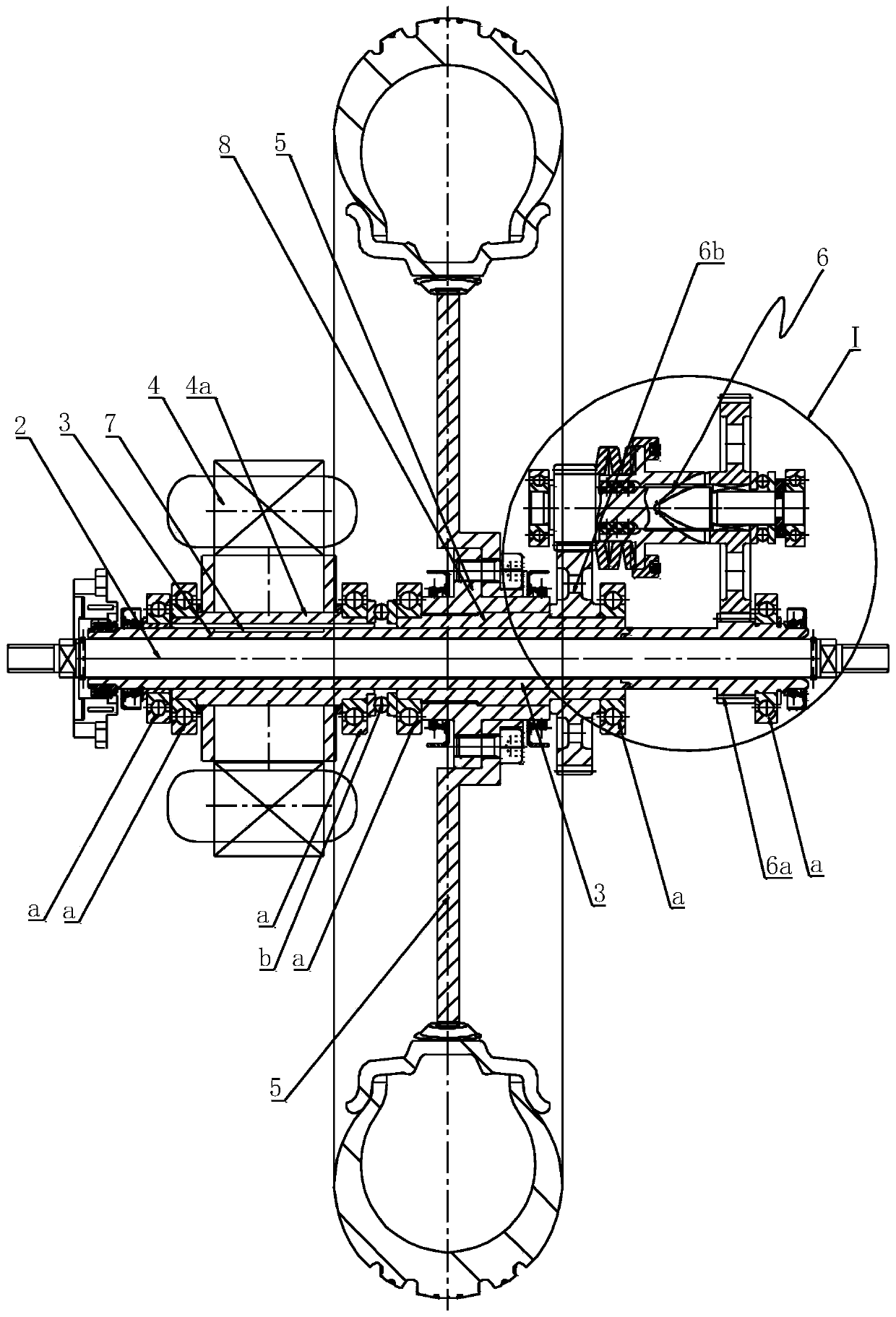

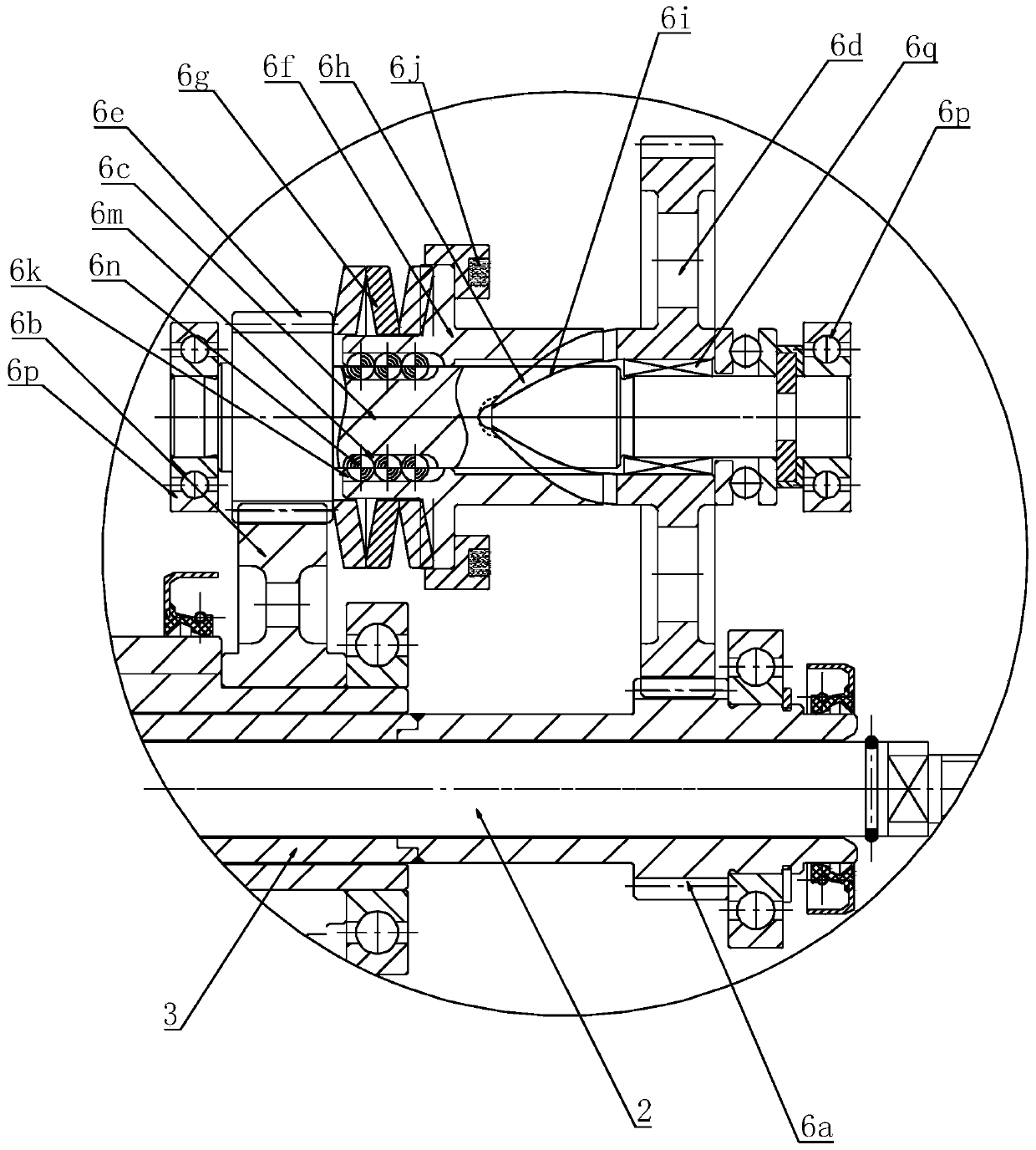

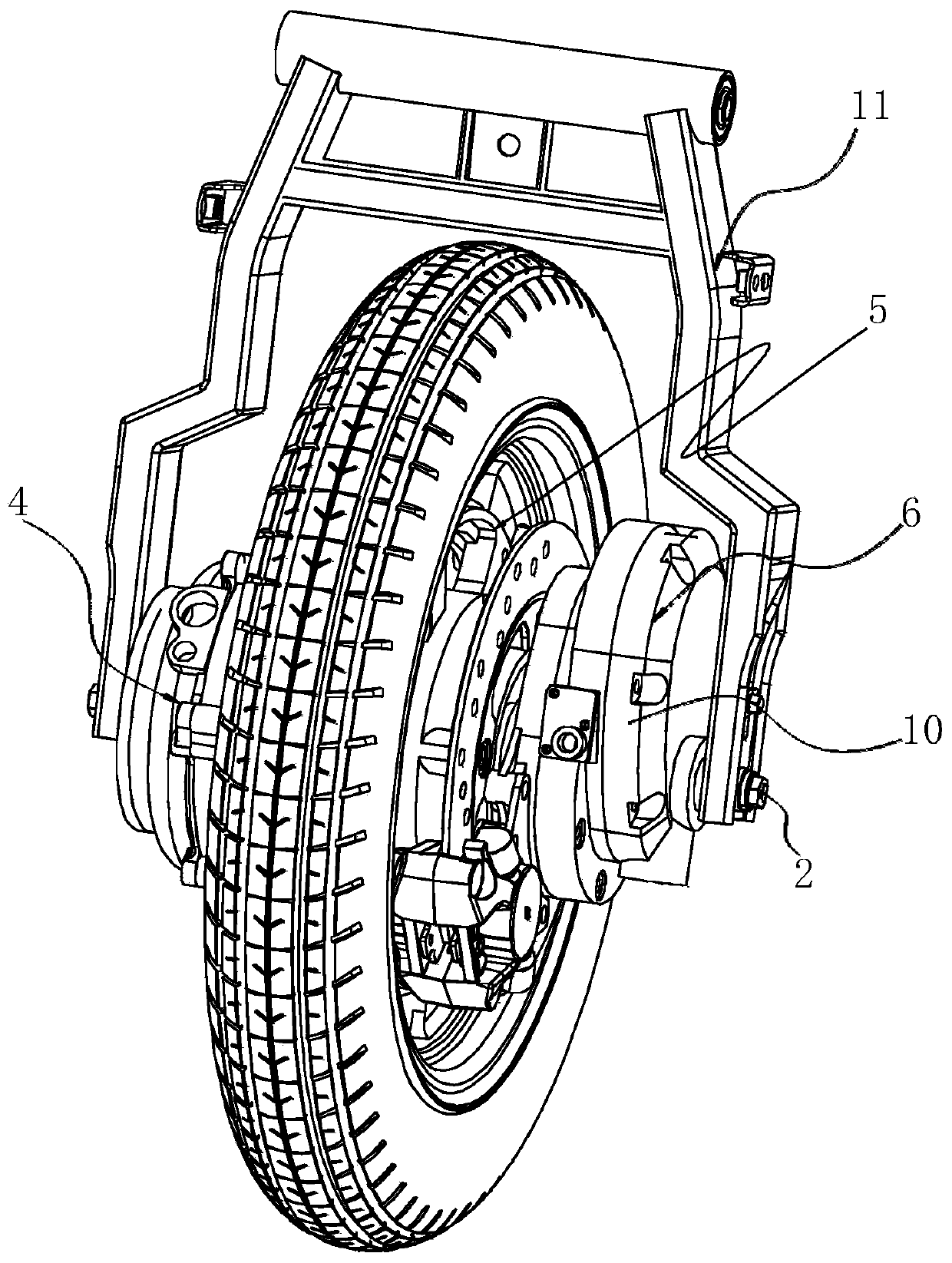

[0024] Such as figure 1 , 2 As shown in and 3, a central drive electric drive system for an electric two-wheeled vehicle includes a fixed shaft 2, and the two ends of the fixed shaft 2 can pass through the outer shell 10 and be fixedly installed on the vehicle wheel frame or flat fork 11, and the fixed shaft 2 Used to support the entire electric drive system, the fixed shaft 2 is covered with a rotating sleeve 3 extending along its length. The rotating sleeve 3 rotates relative to the fixed shaft 2 when it is working. Due to the assembly gap between the rotating sleeve 3 and the fixed shaft 2 , the proper amount of bending deformation generated after the fixed shaft 2 is loaded will not affect the transmission accuracy of the system. The motor 4, the hub 5 and the reduction mechanism 6 are arranged on the rotating sleeve 3 in sequence from left to right. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com