Mechatronic permanent-magnet outer-rotor power generator

A technology for external rotors and generators, applied in the direction of electromechanical devices, magnetic circuit rotating parts, casings/covers/supports, etc., can solve the problems of high manufacturing costs, high installation requirements, and short service life of power generation equipment. Achieve the effects of reducing hidden dangers of mechanical failure, high mechanical transmission efficiency, and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment and accompanying drawing, technical embodiment of the present invention is described:

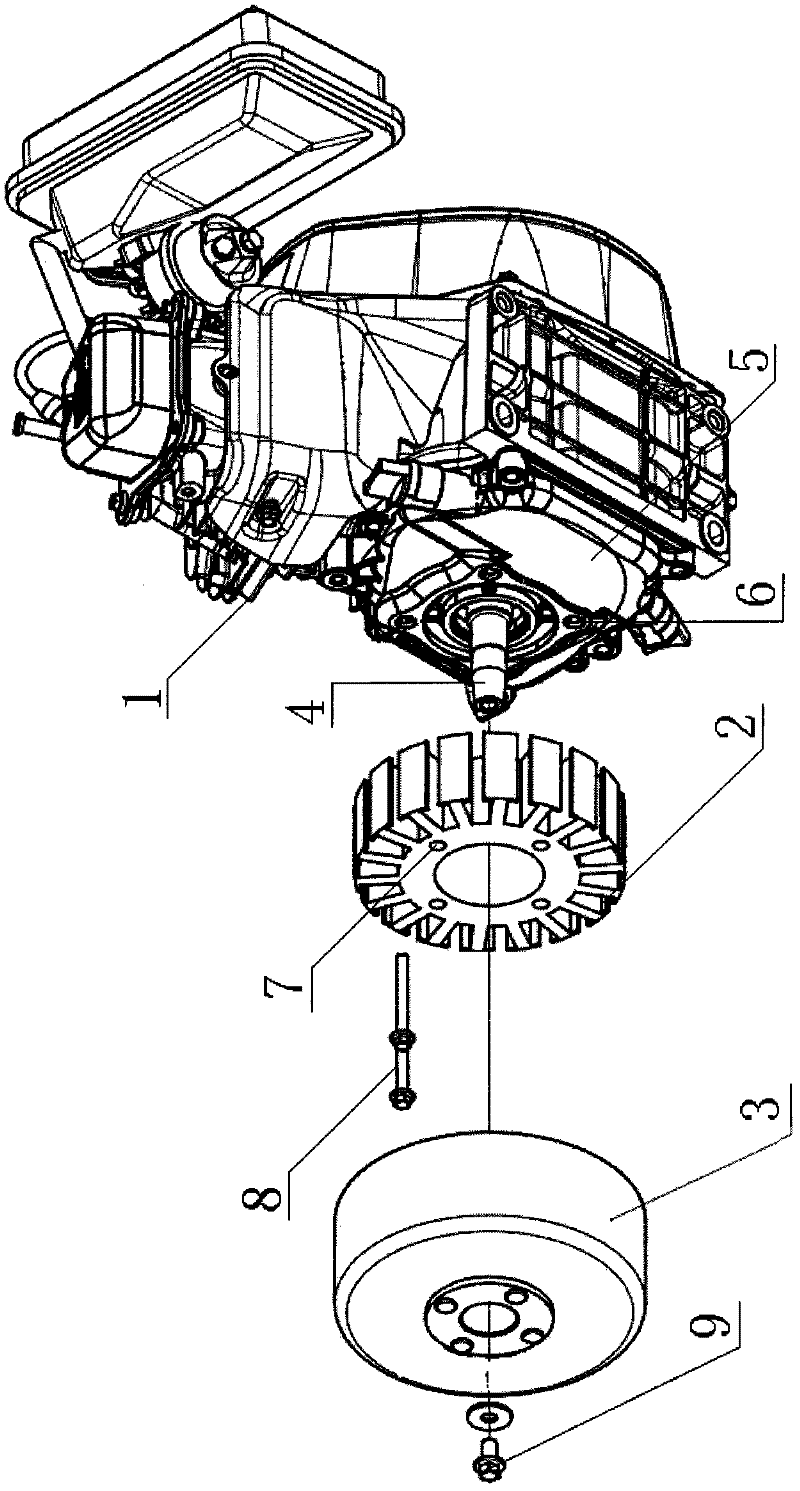

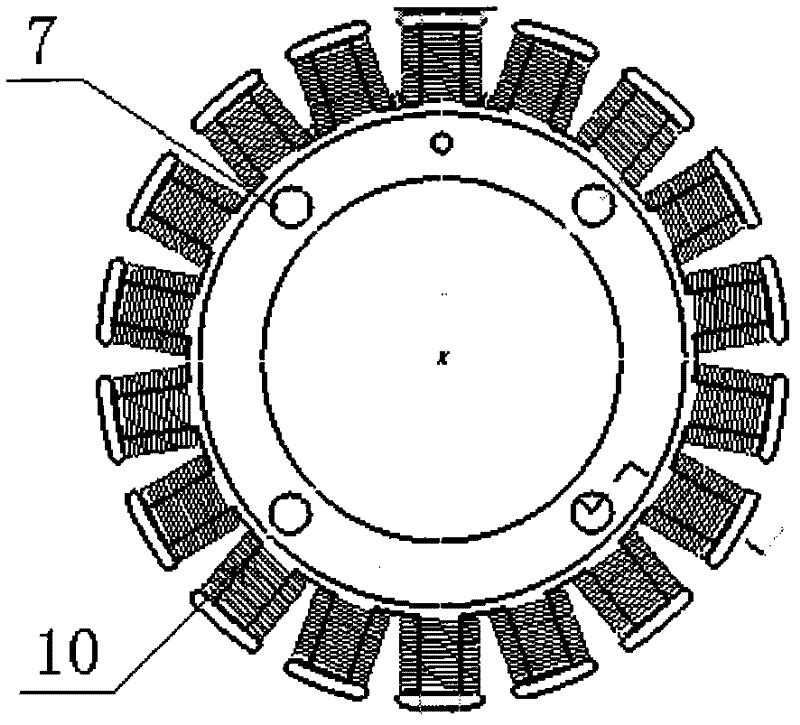

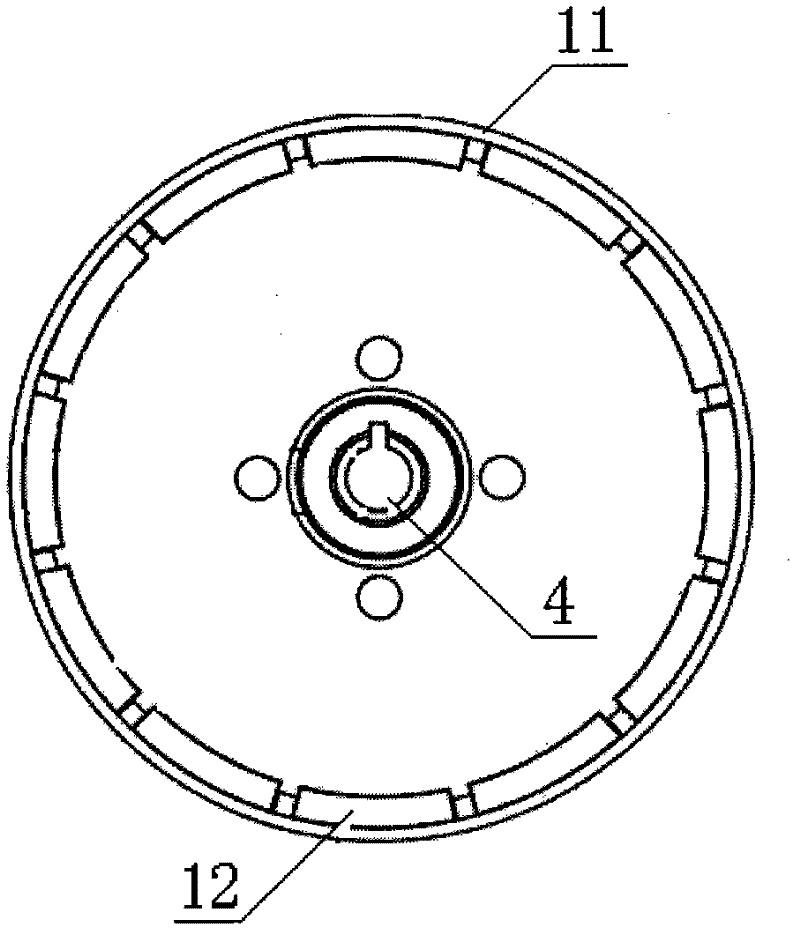

[0022] see figure 1 , the present invention is constituted as follows: an electromechanical integrated permanent magnet outer rotor generator, which is integrated by the engine 1 and the power generation equipment, and the power generation equipment is composed of the generator stator 2 and the power generator located concentrically on the periphery of the generator stator 2 The machine rotor consists of 3 components. On the shaft seat 5 of the engine power shaft 4, a positioning hole 6 is provided with the engine power shaft 4 as the center; on the generator stator 2, a through hole 7 is arranged at a position opposite to the positioning hole 6; the fixed screw rod 8 passes through The through hole 7 is screwed into the positioning hole 6 to fix the generator stator 2 on the shaft seat 5 . In actual production, four screw holes around the midpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com