Planetary gear stepless variable-speed transmission

A planetary gear and continuously variable speed technology, which is applied to wheel transmissions, vehicle gearboxes, vehicle components, etc., can solve the problems of unsealed transmission, unsightly appearance, and large wear and tear, and achieve stable and reliable speed regulation and convenient use , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

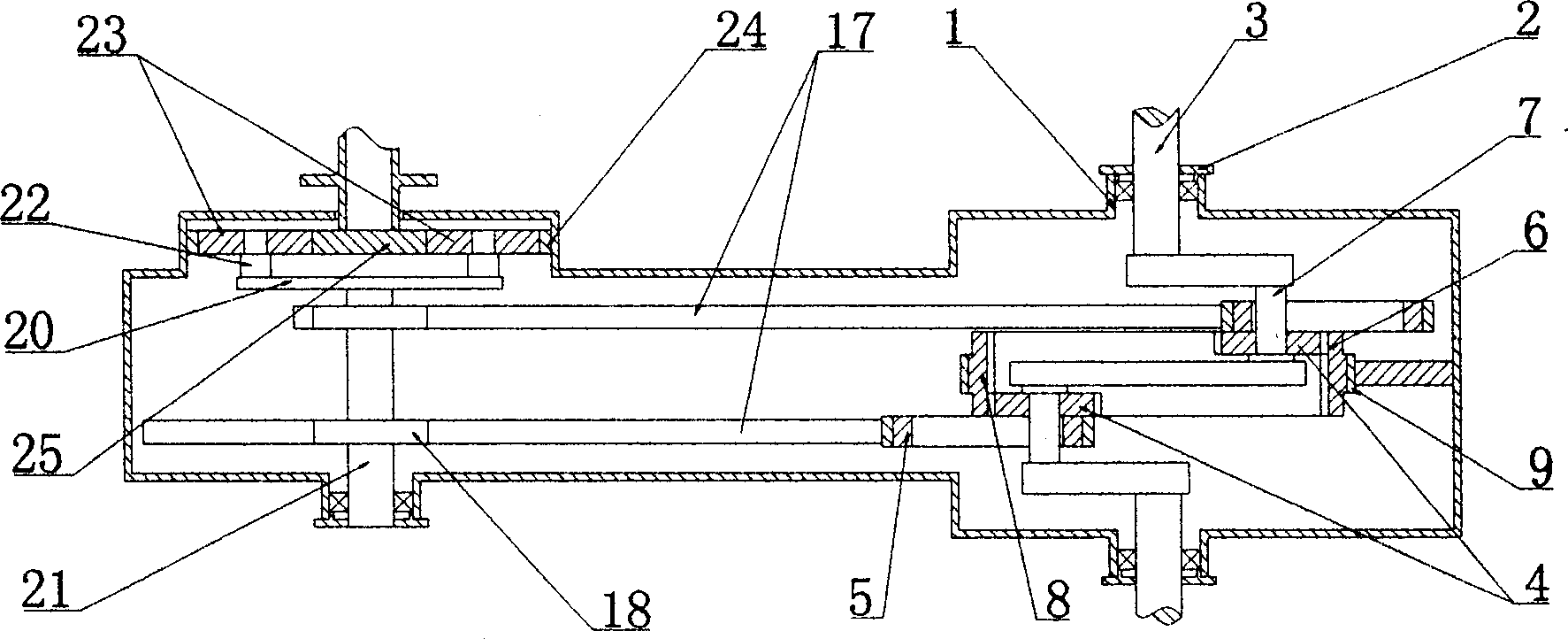

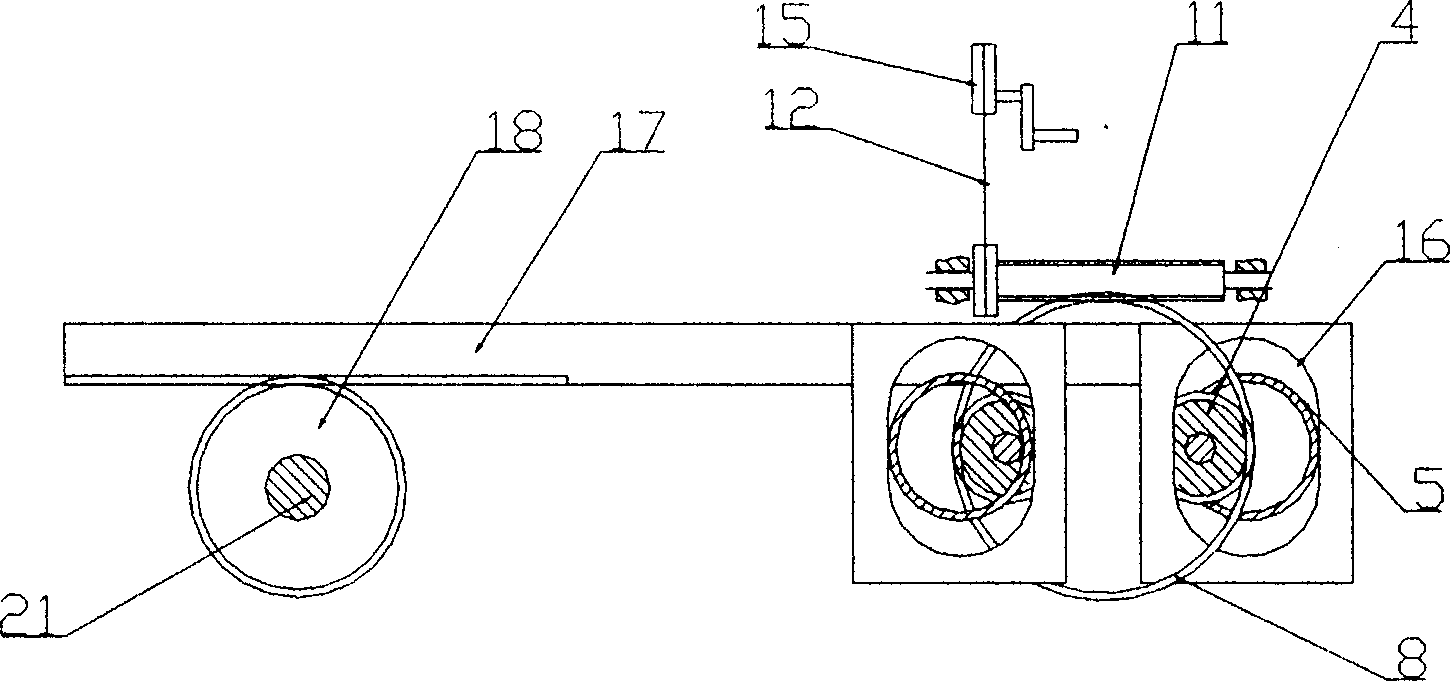

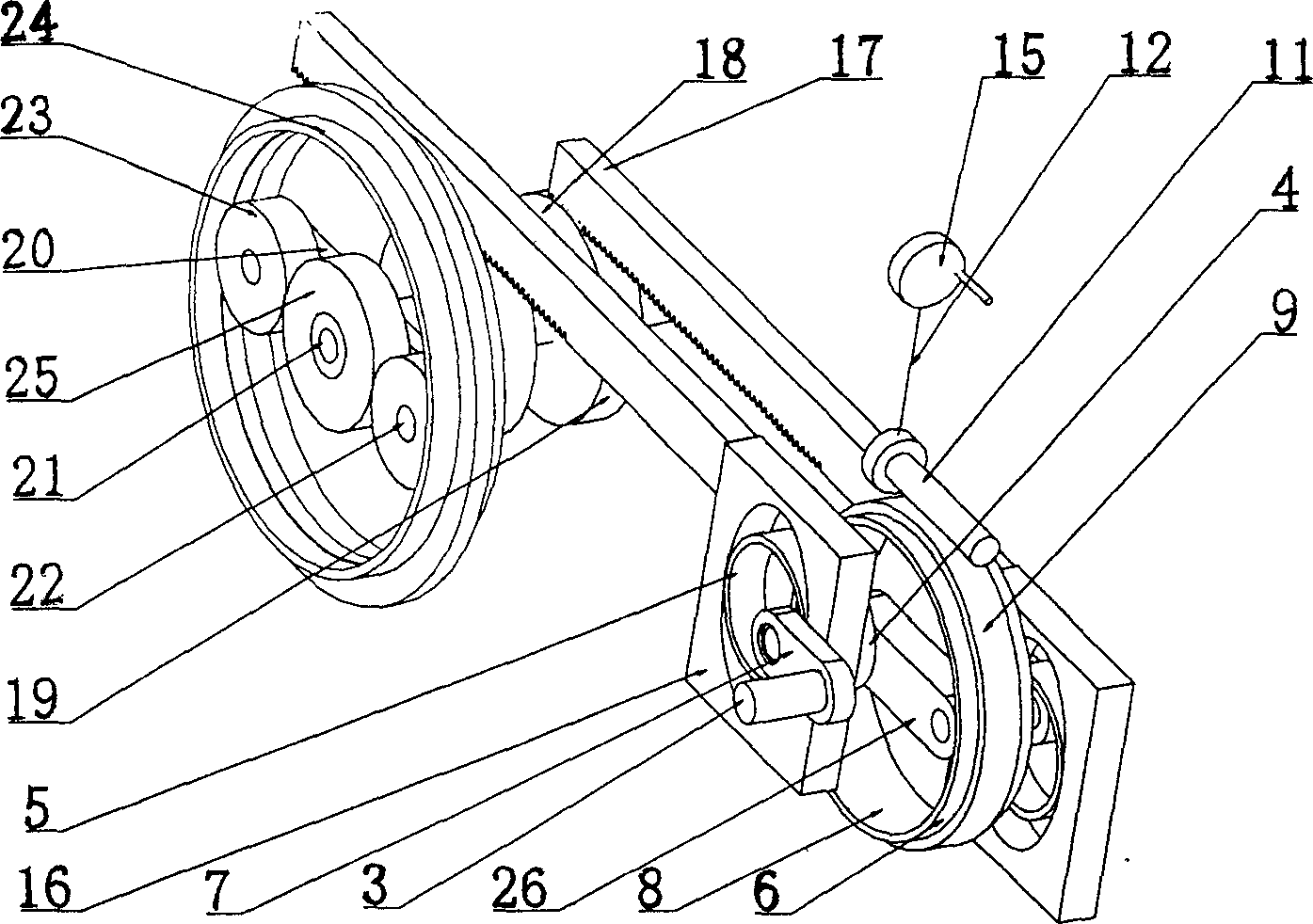

[0016] Such as figure 1 , figure 2 , image 3 As shown, the bicycle planetary gear continuously variable transmission device described in this embodiment mainly includes a planetary gear 4 , a cylindrical ferrule 5 , a ring gear 6 , crank throws 7 , and internal teeth 8 . Two planetary gears 4 are respectively loosely fitted on the bellcrank 7, and a cylindrical ferrule 5 is solidified on the end face of the planetary gear 4, and the planetary gear 4 meshes with the inner tooth 8 on the ring gear 6; the ferrule 5 The center of circle is on the index circle of the planetary gear 4; the central hole of the planetary gear 4 is in the inner circle of the collar 5. In order to adjust the speed conveniently, the ring gear 6 is composed of internal teeth 8 and external teeth 9. The number of teeth of the ring gear 6 is twice the number of teeth of the planetary gear 4 meshing with it. Wire rope 12 is connected with handle wheel 15. The rotary motion input to the shaft in the dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com