Method for separating high-quality molybdenum concentrate from lead-bearing molybdenum ore

A molybdenum concentrate, high-quality technology, applied in solid separation and other directions, can solve the problems of good floatability, increased activity of lead minerals, smaller differences in mineral surface properties, etc., achieving excellent separation effect of molybdenum and lead, and easy operation in production. , the effect of low toxicity of the drug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

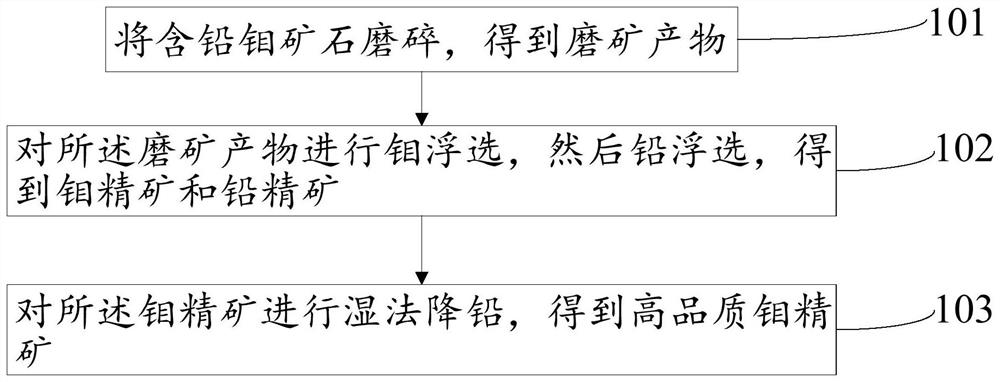

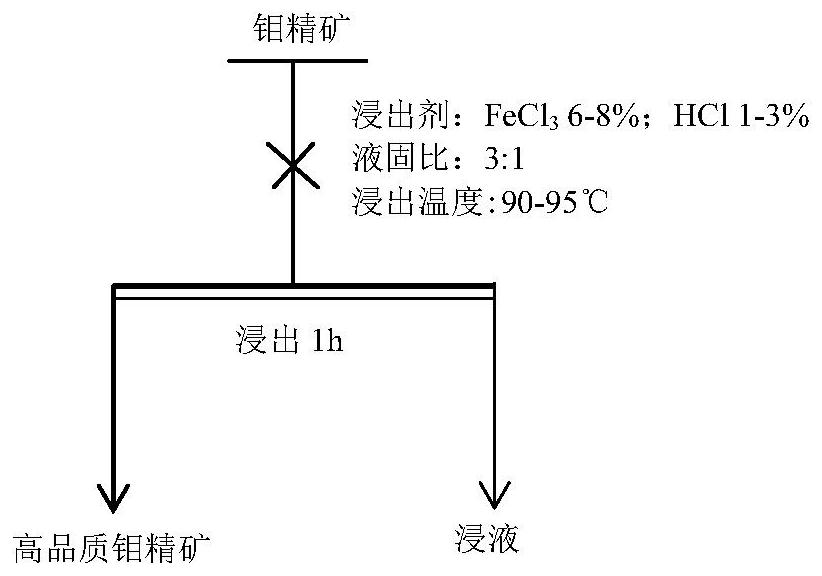

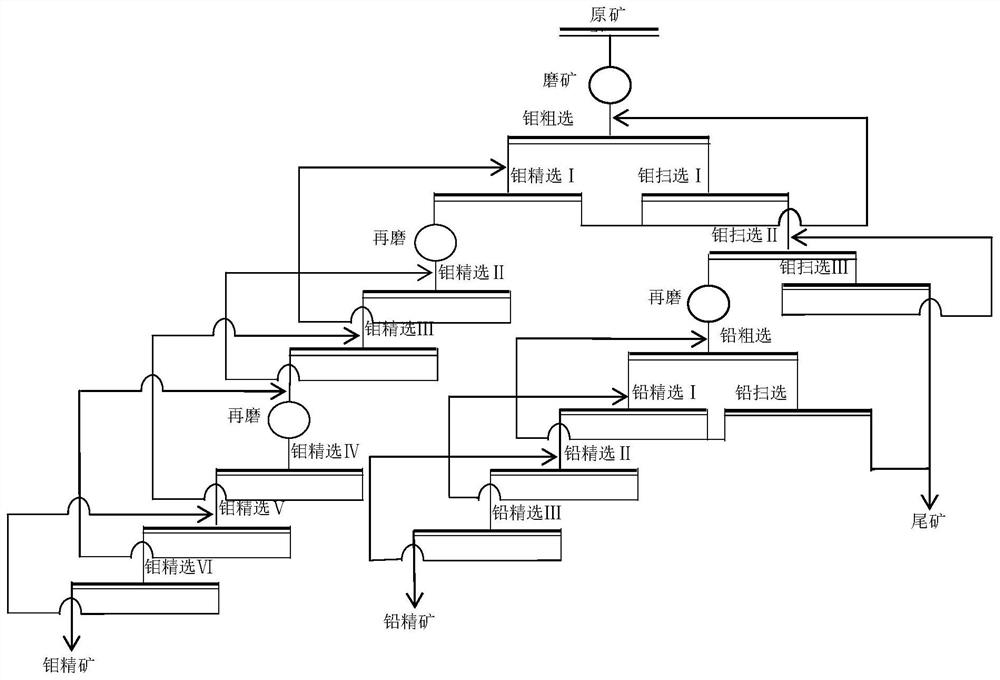

[0089] A molybdenum (lead) mine in Luonan, molybdenum 0.17%, lead 0.51%, such as Figure 1 to Figure 3The process shown in the separation, the grinding fineness is -0.074mm, the content accounts for 65%, the grinding products enter the lead suppression flotation molybdenum (molybdenum flotation), lead selection operation (lead flotation) in turn, and then grind again The fineness is -0.074mm, the content accounts for 88%, and the secondary regrinding fineness is -0.037mm, the content accounts for 85%. Add water glass 60g / t raw ore, phosphorus Knox 55g / t raw ore, diesel oil 50g / t raw ore, No. 2 oil 40g / t raw ore in molybdenum roughing operation. Molybdenum concentration I operation added phosphorus Knox 10g / t raw ore, diesel oil 4g / t raw ore, molybdenum concentration II operation added phosphorus Knox 70g / t raw ore, tannic acid 15g / t raw ore, sodium thioglycolate 30g / t raw ore, diesel oil 10g / t raw ore, No. 2 oil 4g / t raw ore, molybdenum beneficiation III operation added phosp...

Embodiment 2

[0098] A molybdenum (lead) mine in Luonan, molybdenum 0.17%, lead 0.51%, such as Figure 1 to Figure 3 In the process shown in the separation process, the grinding fineness is -0.074mm, and the content accounts for 67%. %, the secondary regrinding fineness is -0.037mm, and the content accounts for 87%. Molybdenum roughing operations add water glass 70g / t raw ore, phosphorus Knox 50g / t raw ore, diesel oil 45g / t raw ore, No. 2 oil 45g / t raw ore. Molybdenum concentration I operation added phosphorus Knox 15g / t raw ore, diesel oil 6g / t raw ore, molybdenum concentration II operation added phosphorus Knox 60g / t raw ore, tannic acid 18g / t raw ore, sodium thioglycolate 25g / t raw ore, diesel oil 15g / t raw ore, No. 2 oil 8g / t raw ore, molybdenum beneficiation III operation added phosphorus Knox 60g / t raw ore, tannic acid 10g / t raw ore, sodium thioglycolate 12g / t raw ore, molybdenum concentration IV added phosphorus Knox 15g / t raw ore, tannic acid 8g / t raw ore, sodium thioglycolate 10...

Embodiment 3

[0108] A molybdenum (lead) mine in Luonan, molybdenum 0.17%, lead 0.51%, according to Figure 1 to Figure 3 In the process shown in the separation process, the grinding fineness is -0.074mm, and the content accounts for 70%. %, the secondary regrinding fineness is -0.037mm, and the content accounts for 90%. Molybdenum roughing operations add water glass 80g / t raw ore, phosphorus Knox 45g / t raw ore, diesel oil 55g / t raw ore, No. 2 oil 50g / t raw ore. Molybdenum concentration I operation added phosphorus Knox 14g / t raw ore, diesel oil 5g / t raw ore, molybdenum concentration II operation added phosphorus Knox 65g / t raw ore, tannic acid 20g / t raw ore, sodium thioglycolate 35g / t raw ore, diesel oil 12g / t raw ore, No. 2 oil 6g / t raw ore, molybdenum beneficiation III operation added phosphorus Knox 50g / t raw ore, tannic acid 13g / t raw ore, sodium thioglycolate 10g / t raw ore, molybdenum concentration IV added phosphorus Knox 13g / t raw ore, tannic acid 9g / t raw ore, sodium thioglycola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com