Coiled material conveying device and adjusting method of conveying device

A coil conveying device and coil technology, which are applied in the direction of coiling strips, transportation and packaging, thin material handling, etc., can solve problems such as increasing power loss, damaging machines, and increasing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

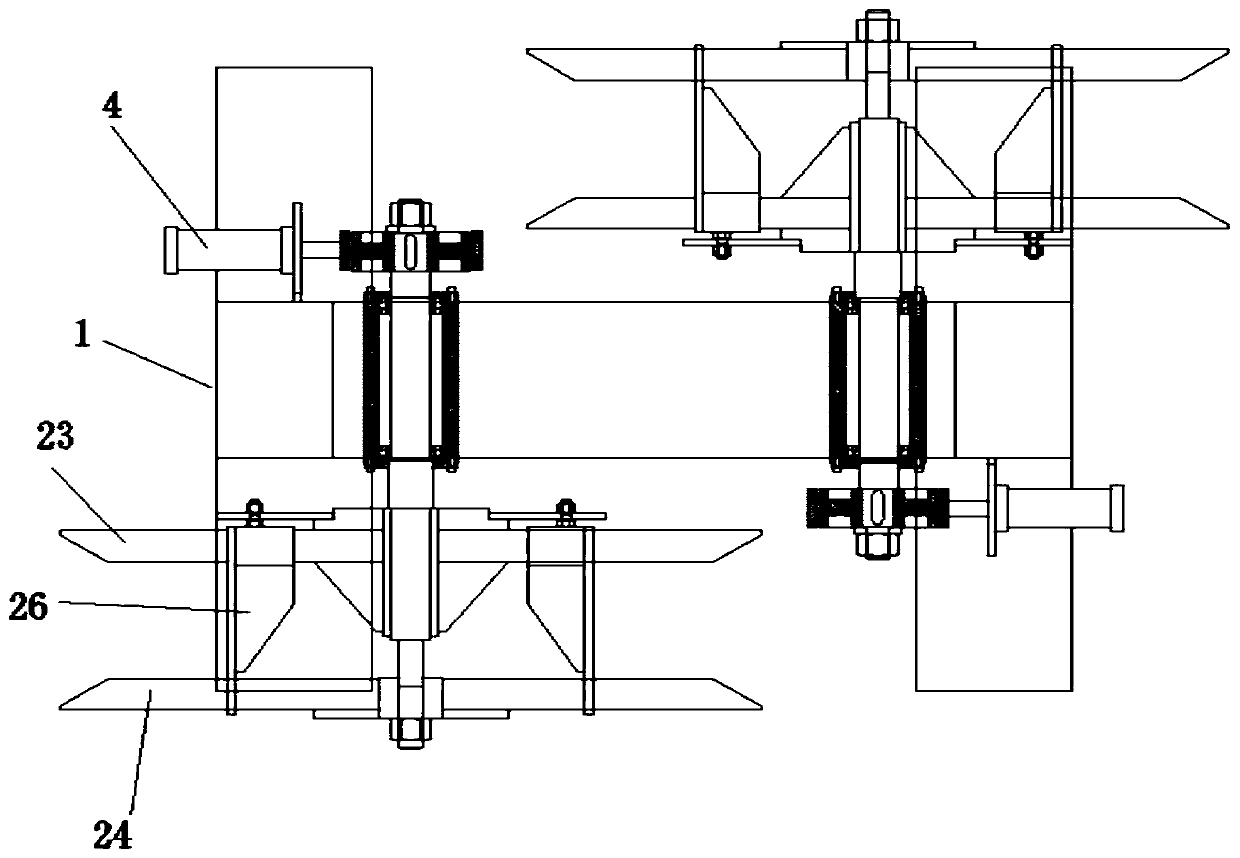

[0046] like Figure 1 to Figure 11 As shown, a coil conveying device includes a frame 1, and also includes:

[0047] The coiled material fixing structure 2 is used to install and fix the coiled material, and rotate synchronously with the coiled material. The coiled material fixing structure 2 can adjust the telescopic position of the tensioning assembly 26 by rotating the first turntable 23 to meet the needs of different coils. The inner ring size of the material needs to be different;

[0048] The brake locking structure 4 is used to quickly brake the coiled material fixing structure 2;

[0049] The stop structure 3 is used to fix the locking disc 25 of the coil fixing structure 2 and assist the adjustment of the tensioning assembly 26 at the same time.

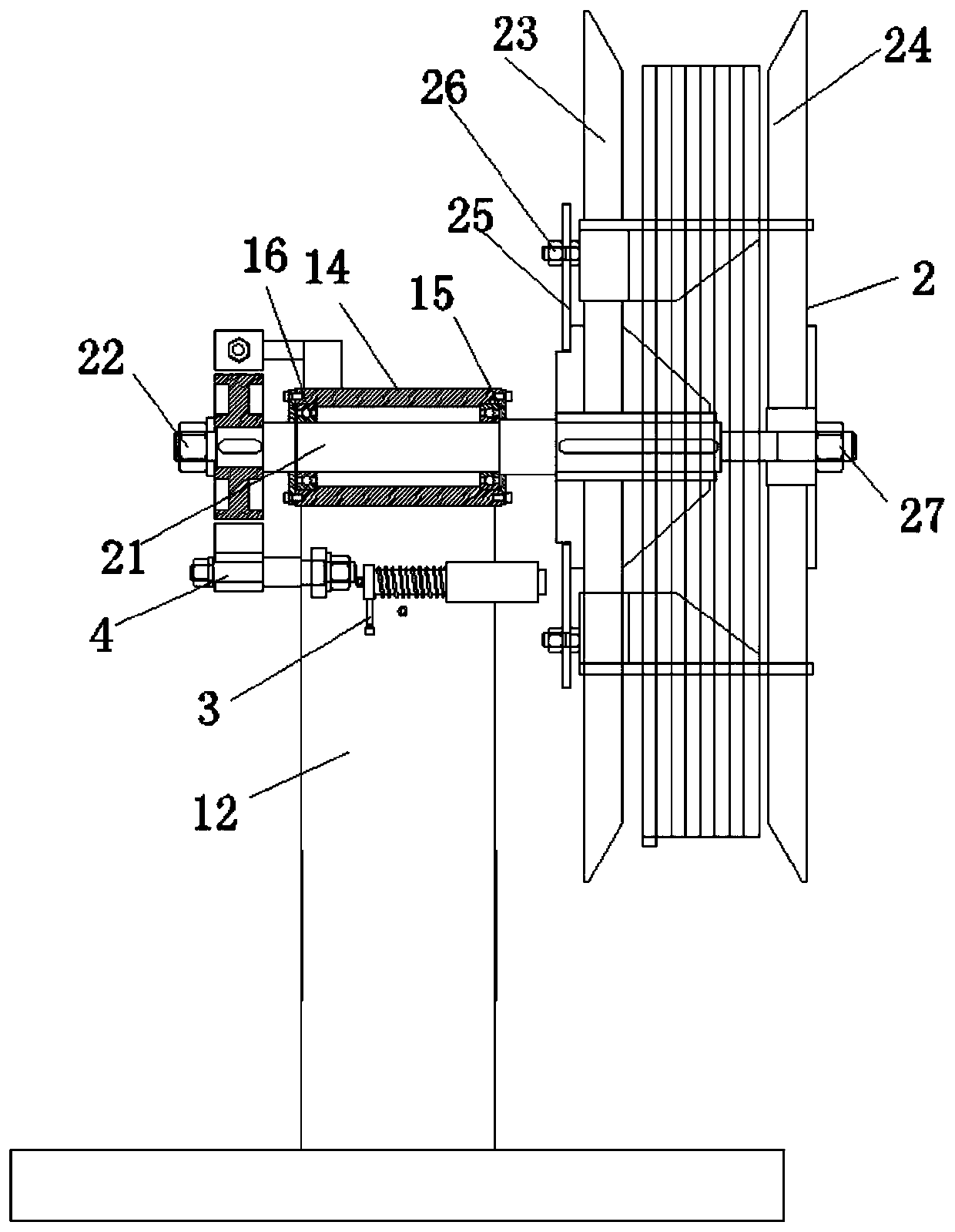

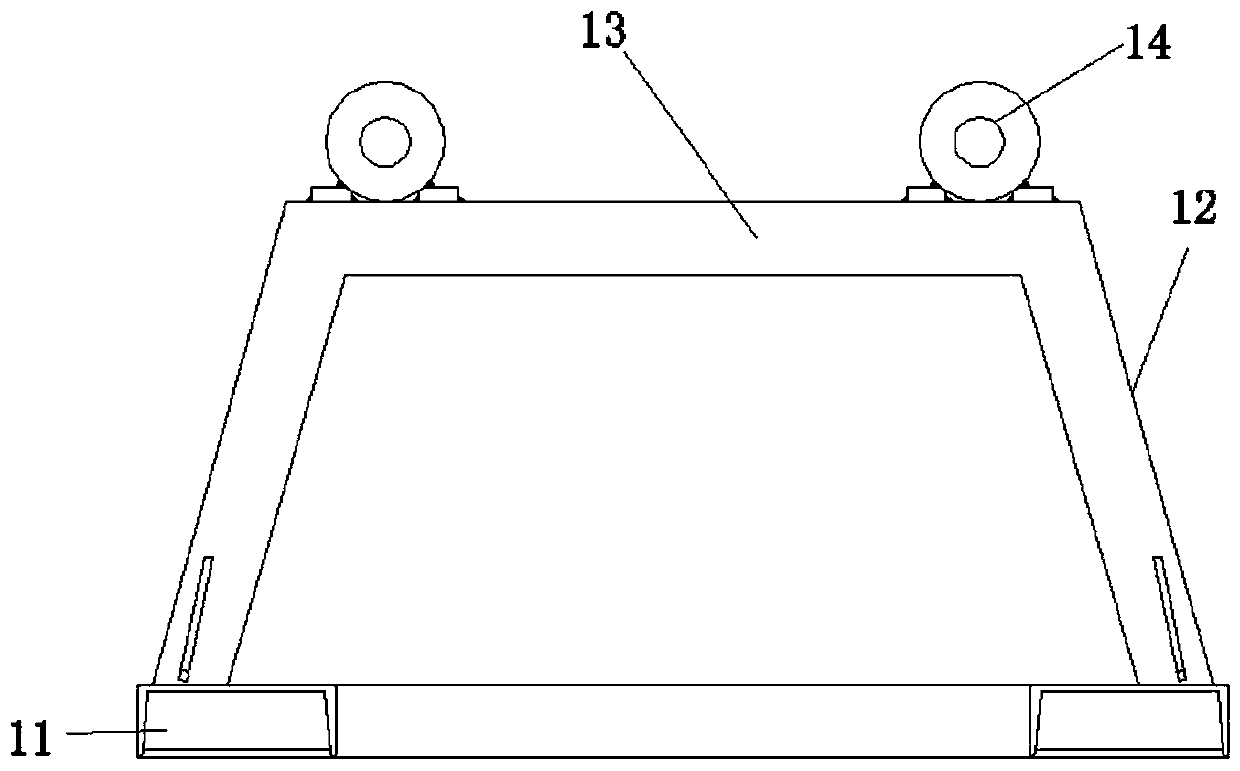

[0050] Described frame 1 comprises base plate 11, support bar 12, cross frame 13, bearing 16 seat 14, shaft cover 15 and bearing 16, and described support bar 12 is fixedly installed on the base plate 11, and described cro...

Embodiment 2

[0062] Embodiment 2, this embodiment is a further description of the coil conveying device of the embodiment, specifically:

[0063] A coil conveying device, comprising a frame 1, a coil fixing structure 2, a brake locking structure 4, and a stop structure 3. The frame 1 includes a bottom plate 11, a support rod 12, a horizontal frame 13, a bearing 16 seat 14, A shaft cover 15 and a bearing 16, the support rod 12 is fixedly installed on the bottom plate 11, the cross frame 13 is mounted on the support rod 12, the bearing 16 seat 14 is mounted on the cross frame 13, and the shaft cover 15 uses Fasteners are installed on both sides of the bearing 16 seat 14, and the bearing 16 is arranged on the inner side of the bearing 16 seat 14;

[0064] The coil fixing structure 2 includes a main shaft 21, a left limiter 22, a first turntable 23, a second turntable 24, a locking disc 25, a tensioning assembly 26 and a right limiter 27. The left limiter 22 Installed on the left end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com