Double chamber parallel electromagnetic control secondary booster automobile brake general pump

An electromagnetic control and secondary boosting technology, applied in the field of automobile brake master cylinder, can solve the problems of major accidents, different requirements of brake performance, and different pipeline connection distances, so as to improve safety and reduce accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

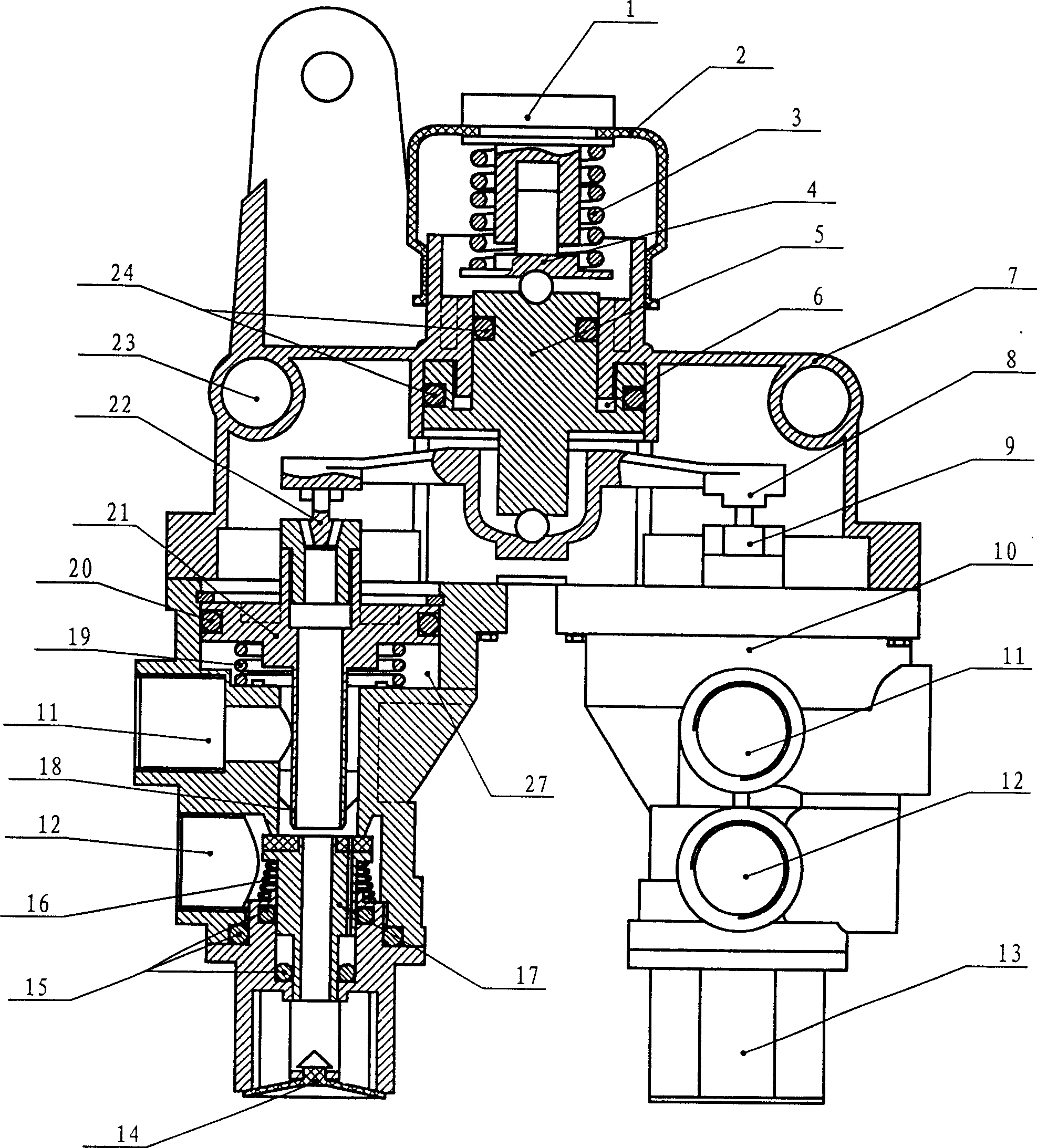

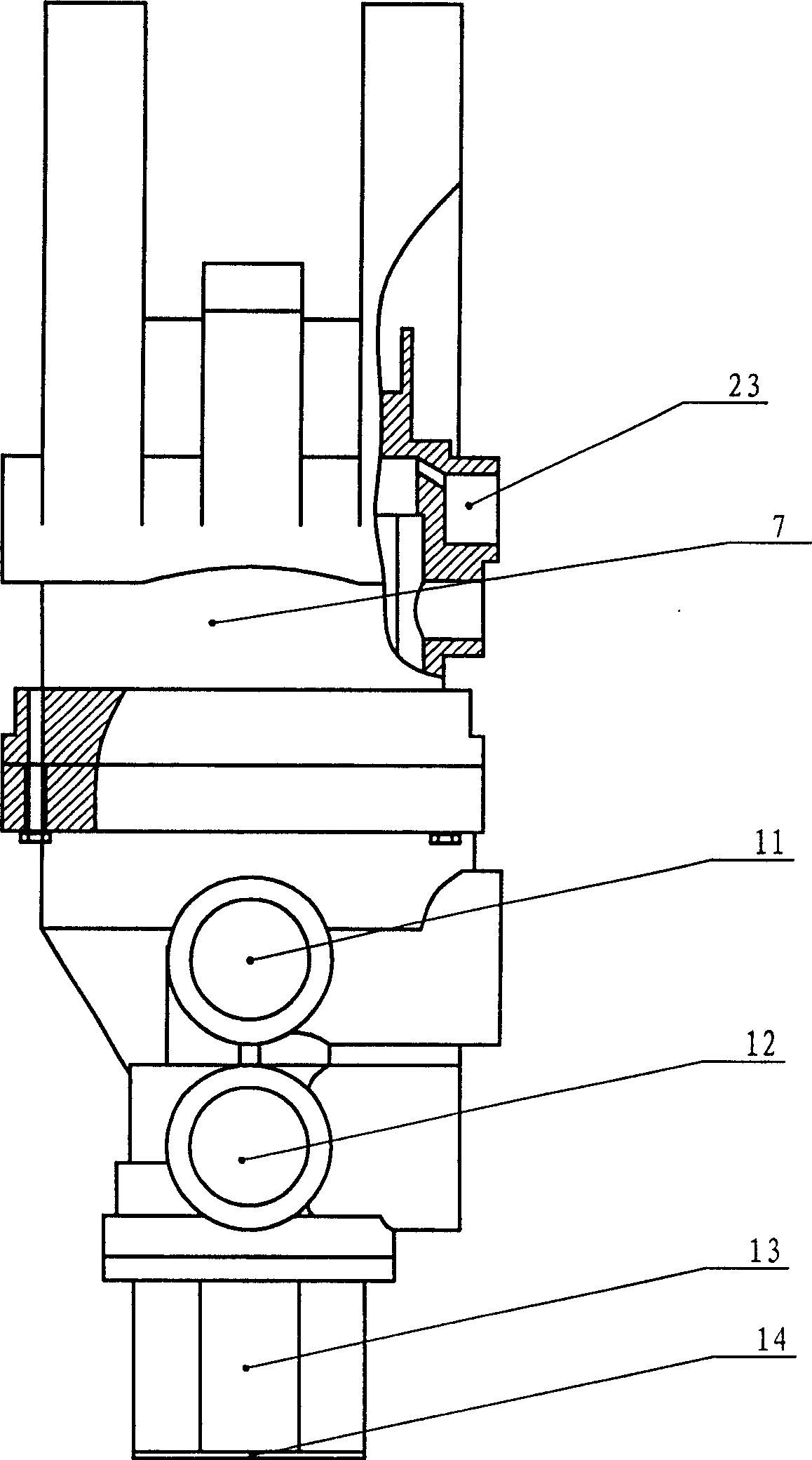

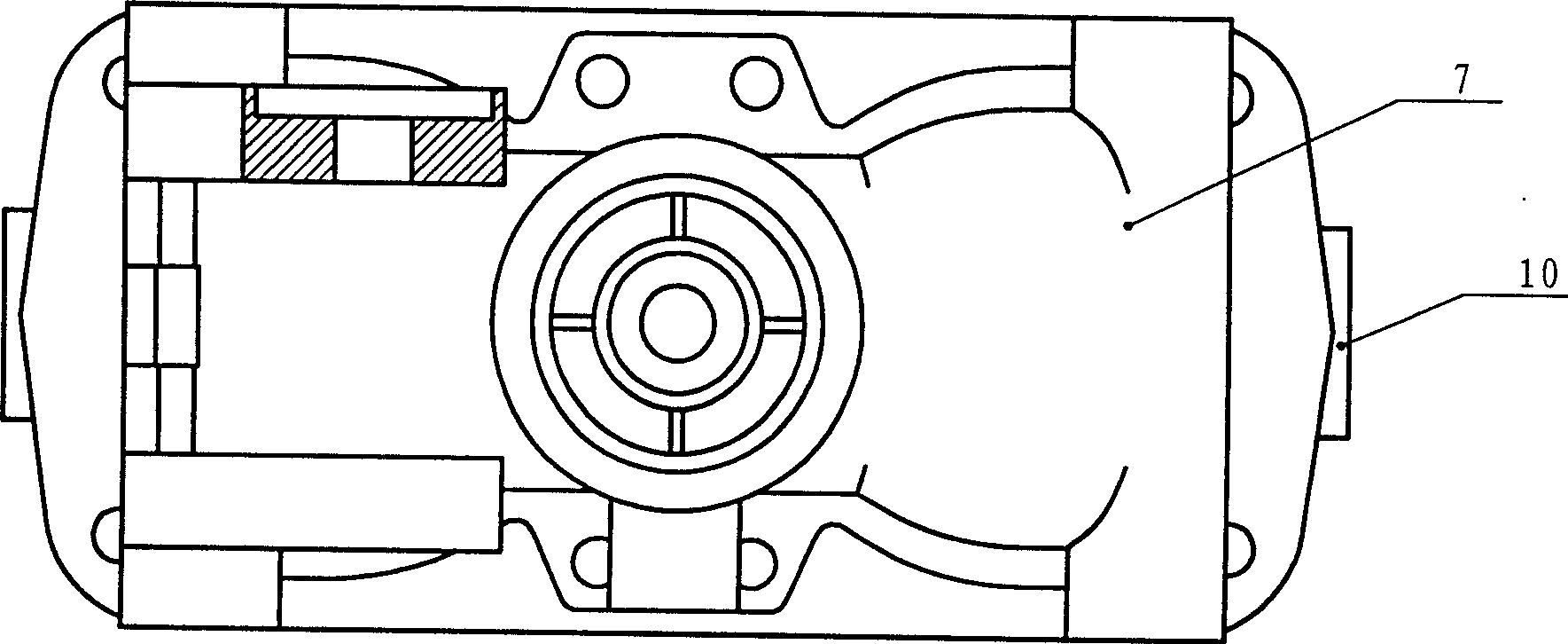

[0023] see figure 1 , figure 2 , image 3 , Figure 4 , in the figure 1-upper part of pressure rod assembly, 2-upper dustproof part, 3-spring, 4-lower part of pressure rod assembly, 5-upper piston, 6-pressurized air chamber, 7-upper pump body, 8- Balance lever, 9-top seat, 10-lower pump body, 11-brake air outlet, 12-brake air inlet, 13-plug, 14-lower dust-proof parts, 15-seal ring, 16-return spring, 17 - valve, 18- lower guide rod of lower piston, 19- return spring, 20- sealing ring, 21- lower piston, 22- ejector rod, 23- pressurizing air hole, 24- sealing ring, 27- surge pressure chamber,

[0024] In the figure, the double-chamber parallel electromagnetic control secondary booster brake master cylinder includes an upper pump body 7 and a lower pump body 10. The lower pump body 10 includes basically the same two parts, and there is an upper piston 5 in the upper pump body 7. assembly, and the balance lever 8 installed on the lower part of the upper piston 5 assembly, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com