A vehicle clutch assembly with sliding fuel saving function

A clutch and clutch shaft technology, which is applied to vehicle components, control devices, transportation and packaging, etc., can solve the problems of not meeting the needs of the maximum driving torque of the vehicle, not suitable for the vehicle to save fuel for a long time, and the maximum torque is limited. It is convenient for product promotion and application, reliable locking and small transmission torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is a specific embodiment of the present invention, and further describes the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to this embodiment.

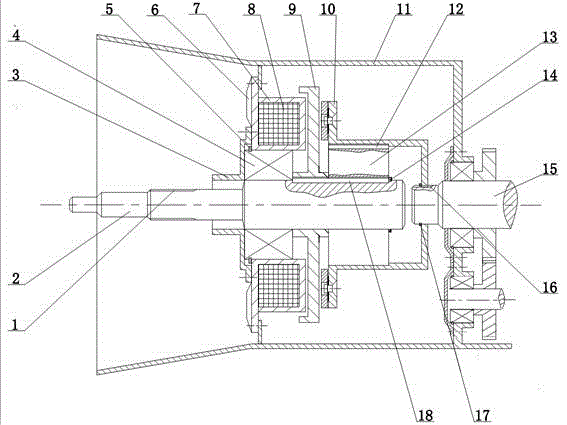

[0027] Such as figure 1 As shown, the clutch assembly housing of the present invention is integrated with the transmission housing, and the main parts include: housing 11, clutch shaft 2, electromagnetic clutch suction disc 7, driving disc 9, driven disc 10, overrunning clutch 13, Clutch shaft bearing 4, transmission input shaft 15 and other components. The spline 1 at the front of the clutch shaft is used to install the driven disc of the traditional dry friction disc clutch, and the rear part of the clutch shaft is connected with the driving disc 9 of the electromagnetic clutch and the active part of the overrunning clutch through the flat key 18—the inner ring, the overrunning clutch The driven part of the outer ring is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com