Air cooling device for secondary ventilation cooling of shield tunneling machine and working method of air cooling device

A ventilation cooling and air cooling technology, applied in mine/tunnel ventilation, refrigerators, compressors, etc., can solve the problems of low reliability of equipment operation, large starting current of the unit, affecting the overall operation, etc., and achieve light weight, single machine Low power, high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described below in conjunction with accompanying drawing and specific embodiment:

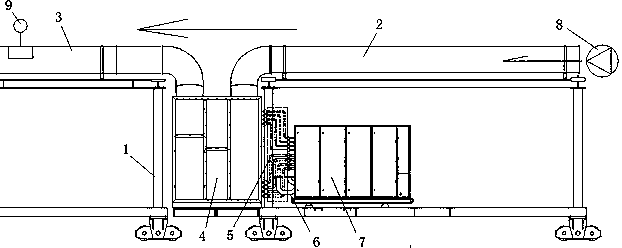

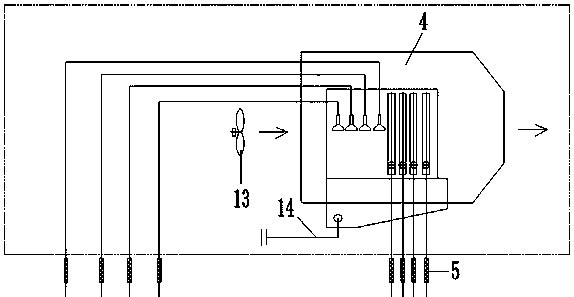

[0039] Such as Figure 1~3 As shown, an air cooling device for secondary ventilation cooling of a shield machine includes a shield machine frame 1, a secondary ventilation cooler 4 and a compression condensing unit 7 are installed on one side of the shield machine frame 1, The secondary ventilation cooler 4 and the compression condensing unit 7 are connected through a shock-absorbing hose 5;

[0040] The top of the shield machine frame 1 is provided with an air inlet pipeline 2 and an air supply pipeline 3, and the air inlet pipeline 2 is connected with the air inlet on the secondary ventilation cooler 3, and the air supply pipeline 3 Connect with the air outlet on the secondary ventilation cooler 3;

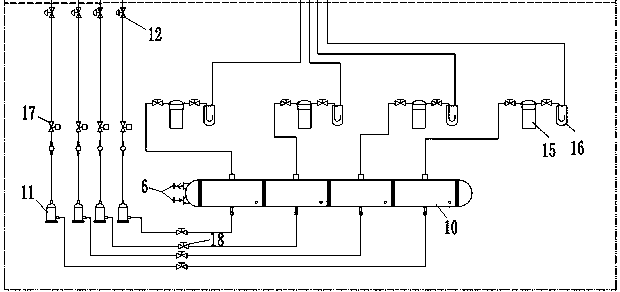

[0041] The compression condensing unit 7 includes a plurality of compressors 15 connected in parallel, and each compressor 15 is provided with a refrigeration cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com