Lock nut assembly

A technology of anti-loosening nuts and components, which is applied in the direction of nuts, threaded fasteners, screws, etc., which can solve the problems that nuts cannot meet the tightening requirements, and achieve the effects of improving friction, improving stability, and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

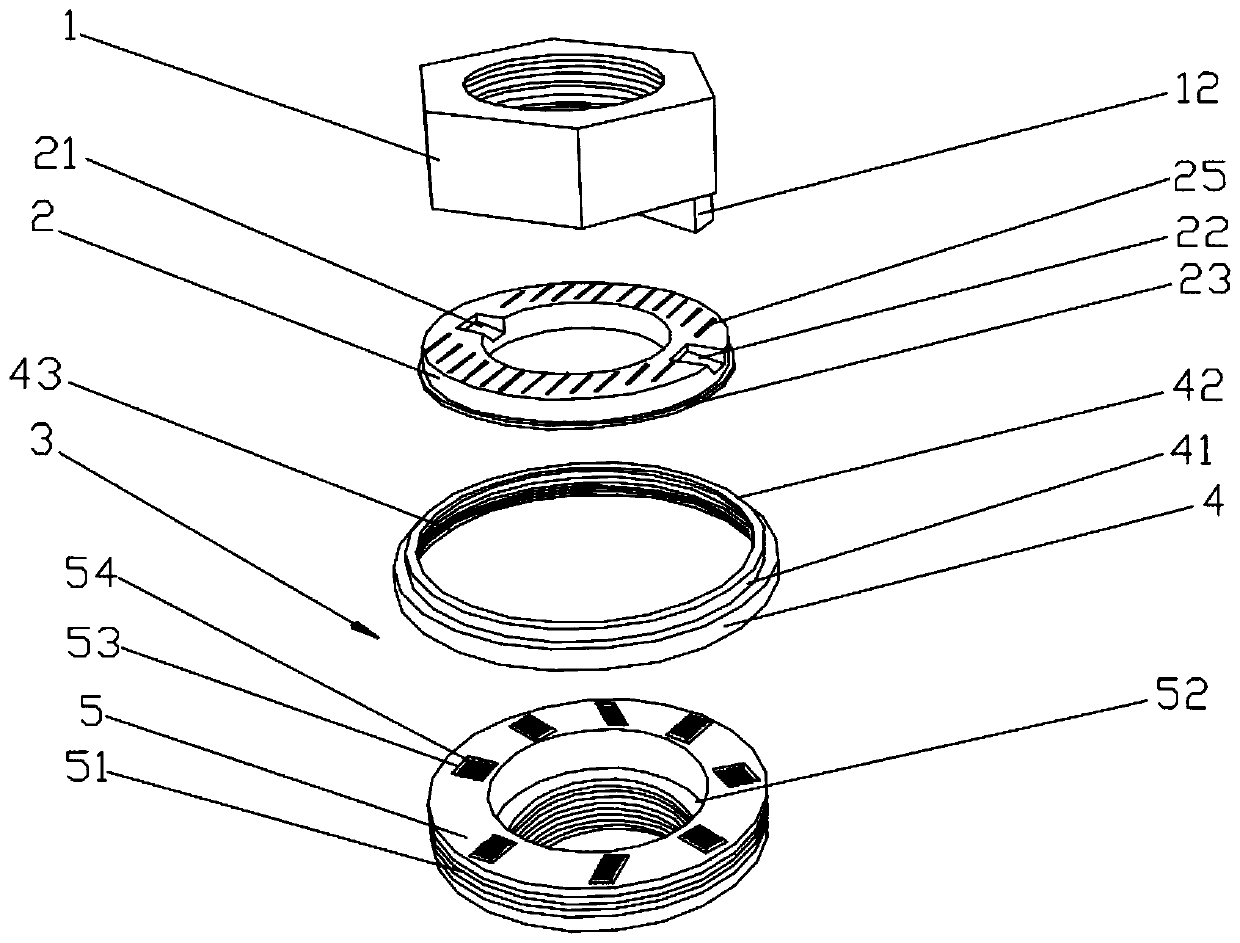

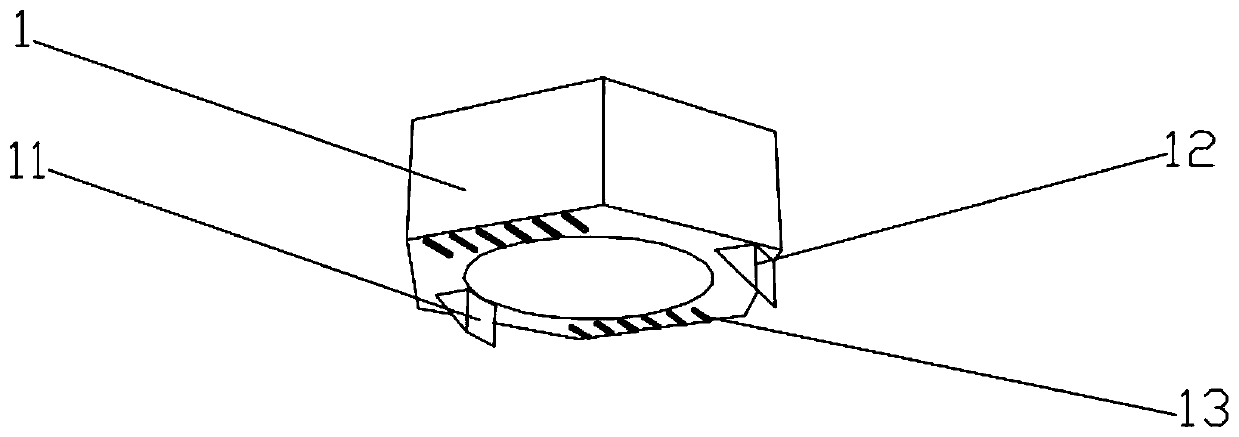

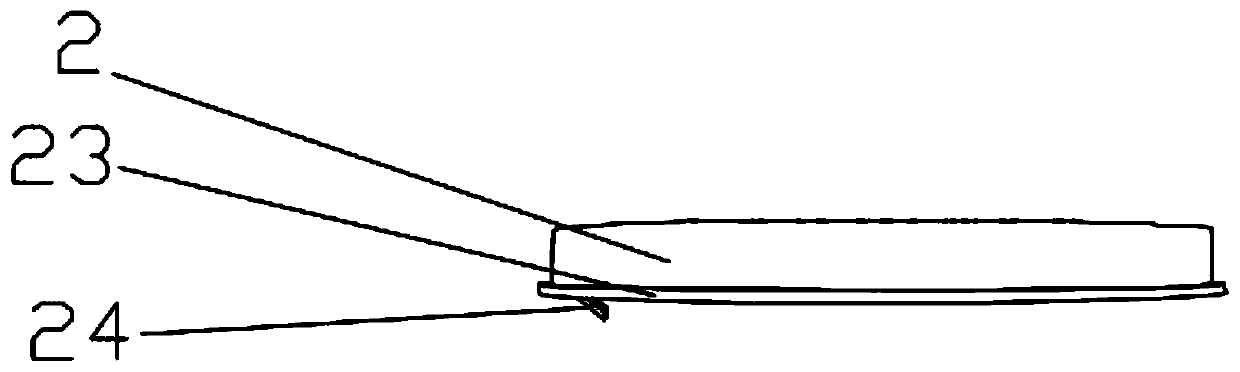

[0026] Such as Figure 1-6 As shown, it is a kind of anti-loosening nut assembly of the present embodiment, which includes nut body 1 and gasket 2 arranged up and down in sequence, the outer movable sleeve of gasket 2 is provided with anti-loosening ring sleeve 3, and the bottom surface of nut body 1 is arranged There are protrusion one 11 and protrusion two 12, both of protrusion one 11 and protrusion two 12 are in the shape of a right triangle, and the right angle sides of protrusion one 11 and protrusion two 12 are all fixedly arranged on the bottom surface of the nut body 1 , the other right-angled sides of the first protrusion 11 and the second protrusion 12 are perpendicular to the bottom surface of the nut body 1, the hypotenuses of the first protrusion 11 and the second protrusion 12 have the same direction, the gasket 2 is a ring-shaped structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com